| Issue |

EPJ Nuclear Sci. Technol.

Volume 11, 2025

Euratom Research and Training in 2025: ‘Challenges, achievements and future perspectives’, edited by Roger Garbil, Seif Ben Hadj Hassine, Patrick Blaise, and Christophe Girold

|

|

|---|---|---|

| Article Number | 43 | |

| Number of page(s) | 17 | |

| DOI | https://doi.org/10.1051/epjn/2025040 | |

| Published online | 15 August 2025 | |

https://doi.org/10.1051/epjn/2025040

Regular Article

OperaHPC & SCORPION: accelerated optimization of advanced fuels for Gen-II/III reactors via the synergy of high-performance computing with multiscale material engineering

1

CEA, DES, IRESNE, DEC, Cadarache, 13108 St Paul Lez Durance, France

2

School of Computing and Engineering, University of Huddersfield, Huddersfield, HD1 3DH, United Kingdom

3

Italian Institute of Technology (IIT), Via Morego 30, 16163 Genova, Italy

** e-mail: bruno.michel@cea.fr

**** e-mail: k.lambrinou@hud.ac.uk

Received:

13

January

2025

Received in final form:

22

April

2025

Accepted:

2

July

2025

Published online: 15 August 2025

The licensing of advanced fuel materials and designs for Gen-II/III reactors requires an extension of the qualification of industrial fuel performance codes to meet the requirements of nuclear safety authorities vis-à-vis the verification, validation, and uncertainties quantification process. To address these requirements, the OperaHPC project works on advanced simulation tools enabling 3D representation of fuel rods. In the first two years of this project, a creep test device for hot cell installation was designed and transmission electron microscopy was used to characterize the microstructure of an irradiated fuel on the nanoscale. In parallel, small-scale simulation and physics-based fuel mechanical modelling were initiated to study dislocation mobility. State-of-the-art fuel and fuel cladding mechanical laws were employed in preparation of advanced mechanical modelling. HPC fuel performance codes are being developed with OFFBEAT/SCIANTIX for macroscale fuel element simulations, and MMM for mesoscale fuel pellet microstructural simulations. The preparation of industrial applications with improved models involves exchanges on machine-learning methods alongside the computation of input data for fuel safety analysis.

SiC/SiC composites are a candidate accident-tolerant fuel cladding material that exhibits inherent refractoriness, pseudo-ductility, and a lack of accelerated oxidation during loss-of-coolant scenarios. Due to its potential for exceptional accident tolerance, this ‘revolutionary’ fuel cladding material concept has claimed large global investments since the 2011 Fukushima Daiichi event. Regrettably, all state-of-the-art variants of the SiC/SiC composite material concept must still overcome shortcomings, such as the inadequate compatibility of SiC with water/steam and its early (> 2 dpa) saturation of radiation-induced swelling during nominal operation. The SCORPION project strives for the radical performance optimization of SiC/SiC composites via multiscale material tailoring, which entails material re-design on the nanoscale (e.g., grain boundary engineering), mesoscale (e.g., fiber/matrix interface), and macroscale (e.g., coating development). In the first two years of this project, candidate coating ceramics and grain boundary engineered/doped SiC were experimentally synthesized and their performance was assessed via autoclave tests, high-temperature steam oxidation tests, and combined proton irradiation/aqueous corrosion tests. The hitherto tested materials performed significantly better than monolithic SiC, highlighting the success of the multiscale material engineering approach.

This article offers a high-level overview of the scope and midterm achievements of the OperaHPC & SCORPION projects, in view of the FISA-EURADWASTE & SNETP Forum 2025, organized in Warshaw, Poland, in the period 12-16 May 2025.

© B. Michel et al., Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1. Introduction

Generation II/III reactor fuels in Europe take advantage of a large pool of experimental data with a continuous evolution of fuel element design and materials, which allows maintaining high safety standards while adapting to the evolution of the reactor operating conditions. Fuel performance codes enable the simulation of the in-reactor behavior of fuel elements and constitute an essential component of the design, licensing and safety assessment of nuclear fuels. The licensing of innovative materials and fuel designs requires an extension of the qualification of industrial fuel performance codes to meet the requirements of nuclear safety authorities regarding the verification, validation, and uncertainties quantification process. To address these questions, the OperaHPC project [1] proposes the development of advanced simulation tools that enable the 3D representation of fuel rods. More specifically, the project aims at contributing to the fuel performance code qualification using advanced simulation tools with physically based modelling and high-performance computing capabilities. The project activities range from fundamental research, with experimental characterization of fuel creep behavior coupled with small-scale simulations, to representative engineering fuel safety studies, using improved industrial fuel performance codes and high-performance computing (HPC) 3D simulations. The latter is also improved in the OperaHPC project with the development of open-source codes, such as OFFBEAT at the fuel rod scale and MMM at the fuel microstructure scale. Moreover, machine-learning techniques are developed to enhance the transfer between 3D simulations and industrial models.

On the other hand, the SCORPION project strives for the accelerated development of SiC/SiC composite accident-tolerant fuel (ATF) cladding materials with radically improvement performance vis-à-vis coolant (water/steam) compatibility and resistance to radiation swelling for use in Gen-II/III light water reactors (LWRs). SCORPION is primarily an experiment-oriented project with select modelling activities, e.g., the effect of void swelling on the thermal conductivity of irradiated SiC-based fuel claddings will be simulated with the 2D fuel performance code Falcon in conjunction with the 3D OFFBEAT code also employed in OperaHPC. SCORPION adopts a modular material engineering approach connecting the nanoscale to the macroscale; more specifically, material tailoring on the nanoscale entails grain boundary engineering and doping to limit hydrothermal ageing and radiation swelling; the judicious (mesoscale) modification of the fiber/matrix ‘interphase’ aims at improving material stability under neutron irradiation and in high-temperature oxidizing environments after the onset of matrix microcracking (i.e., at the initial stages of damage of SiC/SiC composites under tension); and the development of protective coatings (macroscale) targets the effective prevention of in-reactor degradation of SiC-based materials in contact with water and steam. Such radical materials engineering across scales is challenging for the conservative nuclear sector, where nuclear materials innovation typically follows the well-trodden path of incremental material improvement, followed by time-consuming neutron irradiation campaigns and post-irradiation examinations (PIEs) before material deployment to market; unfortunately, this traditionally slow approach is not suited for the expedited development of ATFs that are designed to enhance nuclear energy safety as soon as technically feasible.

This article describes the incentive, midterm status, and selected results of the OperaHPC and SCORPION projects, as they both focus on advanced fuels for Gen-II/III LWRs. Prospects of exchanging reliable and pertinent experimental data as well as cross-fertilization of ideas on simulations approaches will be explored by the two projects in the future.

2. The OperaHPC project

2.1. Objectives

The OperaHPC (“Open HPC thermomechanical tools for the development of eAtf fuels”) project focuses primarily on the simulation of the in-reactor behavior of fuel elements [2]. This simulation is implemented in fuel performance codes [3–6], using a multi-physics computational scheme (see Fig. 1) that describes each individual fuel element comprising the fuel pellet column and the fuel cladding. For the fuel rod concept, the numerical algorithm adopts usually a multi-layered approach with an axial decomposition that uses global and local scales (see Fig. 1). Depending on the geometrical assumption used at the local scale, two types of fuel performance codes can be defined with the industrial modelling based on a one-dimensional cylindrical assumption, on one hand, and the advanced modelling based on a detailed two-dimensional or three-dimensional Finite Element (FE) discretization, on the other hand. The fuel performance codes are the cornerstones for fuel licensing, in combination with data collected from costly neutron irradiation experimental programs that require long periods for preparation and execution (typically, between 5 and 10 years). The planning and execution of irradiation campaigns on innovative nuclear materials are further challenged by the decrease in available irradiation facilities, alongside the emergence of new reactor operating conditions and/or innovative designs. Therefore, the objectives of the OperaHPC project have been carefully defined in such a manner to contribute to the fuel performance code qualification using advanced simulation tools with physically based modelling and HPC capabilities. The main motivation behind this plan is to address the challenge of reducing the licensing period needed for the qualification of enhanced ATFs (eATFs) by accelerating the transfer of know-how from the research & development (R&D) stage to the end-users of fuel performance codes. Therefore, the strategic objectives of the OperaHPC project are:

-

a fundamental research activity with focus on the fuel pellet mechanical properties;

-

the development of open-source fuel performance codes with an advanced 3D simulation, using HPC capabilities;

-

the improvement of the current industrial models by means of machine-learning-type techniques;

-

the production of representative industrial studies for pressurized water reactor (PWR) and water-water energetic reactor (VVER) eATFs with improved codes; and

-

the education & training of researchers, as well as the dissemination of project results.

|

Fig. 1. Multi-physics computational scheme used in fuel performance codes. |

To achieve its scientific and technical (S&T) objectives, the OperaHPC project involves 9 research institutes (CEA, France; CIEMAT, Spain; ENEA, Italy; JRC Karlsruhe, Belgium; LEI, Lithuania; NNL, UK; PSI, Switzerland; UJV Řež, Czech Republic; VTT, Finland), 5 universities (Bangor University, UK; EPFL, Switzerland; KTH, Sweden; POLIMI, Italy; UNIPI, Italy), and 4 industrial partners, 2 of which are SMEs (EDF, France; Framatome SAS/GmbH, France/Germany; NINE, Italy; SINTEC, Italy).

2.2. Fuel mechanical properties

The fundamental research activities focusing on the fuel pellet mechanical properties is distributed in two work packages (WPs), i.e., WP1 and WP2. The main topics addressed in these WPs are (a) the development of an experimental device for creep tests on irradiated fuel samples, (b) the determination of fuel mechanical property data yielded by the synergy of experimental characterization and multiscale modelling, and (c) the improvement of physics-based mechanical laws for fuel and fuel cladding.

The design of the mechanical setup for the creep test experiments has already been completed (see Fig. 2). The mechanical device is shown in Figure 2 will be used to perform compression tests on small-irradiated fuel specimens at high temperatures, in a hot cell of the LECA-STAR lab at the IRESNE institute of the CEA. The design enables direct implementation in the MERARG device [7] used for thermal annealing and fission gas release experiments, thus providing the heating system and the oxygen partial pressure control instrumentation needed for creep testing.

|

Fig. 2. Schematic diagram and computer-assisted design of the mechanical device used for creep tests on irradiated fuels [8]. |

In parallel, the selection and preparation of the irradiated fuel samples has been done, in order to start the detailed materials characterization by means of scanning electron microscopy (SEM) and transmission electron microscopy (TEM) at the microanalysis unit of the LECA-STAR hot lab. For two samples of 13 and 37 GWj/tM (see Fig. 3), the dislocations induced by irradiation have been characterized in detail by means of TEM [9]. These measurements provide the input data needed by the micromechanical modelling to assess irradiation-induced hardening.

|

Fig. 3. Characterization of the dislocations induced by irradiation in the samples before the mechanical creep test. The fuel burnups of 13 GWj/tM and 37 GWj/tM correspond to the total energy produced per unit volume of fuel during one cycle and two cycles, respectively [9]. |

To contribute the understanding of irradiation effects on fuel creep behavior, dislocation mobility simulations have used interatomic potentials and dislocation dynamics. In the fluorite crystal of uranium dioxide (UO2), thermally activated dislocation gliding is involved in the in-reactor fuel creep behavior at the temperatures experienced by the fuel pellet. In order to compute the physical data associated with dislocation velocity, molecular dynamics (MD) simulations have already been performed in the OperaHPC project. Based on these simulations [10], a cross-slip law has been proposed in the dislocation dynamics simulations to describe the complex behavior of screw dislocations in the three available gliding directions in UO2 (see Fig. 4a).

|

Fig. 4. (a) Screw dislocation mobility in UO2 [10]. (b) UO2 phase change ahead of the tip of a crack propagating under tension [11]. |

Rupture physical data have also been computed by means of MD simulations of a tensile test on a specimen that included an ellipsoidal notch of a few nanometers in length. The fracture toughness, KIC, was derived from the elastic energy restitution rate, which was computed by the energy absorbed during crack propagation and the crack surface increments due to crack growth. These simulations showed that the energy needed for surface separation can include, in some conditions, a dissipative phase change that occurs in the stress concentration zone ahead of the crack tip (see Fig. 4b).

The improvement of physics-based mechanical laws for fuel and fuel cladding has also started in the framework of WP2. A state-of-the-art analysis has been distributed to the partners to collect available material data and define a common methodology enabling the multiscale description of heterogeneous materials. Following the bibliographic study, it has been decided to use the crystal plasticity framework and the nonuniform transformation field analysis (NTFA) homogenization technique to describe the microstructure of polycrystalline UO2. Concerning the fuel cladding, the partners have decided to focus on an eATF material concept, i.e., the chromium (Cr)-coated zircaloy ATF cladding material, with a surrogate model describing the heterogeneity due to the thin external Cr coating [12]. The next steps include the transfer of physical data yielded in WP1 for creep and rupture into the new physics-based laws for UO2. Another output of the state-of-the-art concerns the use of the open-source tool MFront for the numerical implementation of the new mechanical laws in the fuel performance codes developed within the OperaHPC project.

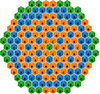

2.3. 3D HPC fuel performance code

The codes developed in the OperaHPC project (WP4) are named OFFBEAT [3] and MMM [13] and are dedicated to the fuel rod engineering scale (macroscale) and the heterogeneous material microstructure scale (microscale), respectively (see Fig. 5). To complete the OFFBEAT muti-physics modelling for fission gas behavior and irradiation-induced microstructural effects, the SCIANTIX code [14] is also developed in this project. The main idea behind these codes is to provide open-source tools enabling 3D simulation using HPC capabilities. In addition, a prototype tool is developed to take advantage of the Smooth Particle Method for the simulation of phenomena where the geometry update is challenging for both FE and finite volume (FVM) methods. The physics of fuel thermomechanical behavior to be addressed by these codes focuses on the assessment of fuel cladding integrity in case of Pellet-Cladding Mechanical Interaction (PCMI) and on fuel column integrity in case of Fuel pellet Over-fragmentation (FO). In addition to this, WP3 will provide an integration of these open-source codes in the existing computational framework of legacy fuel performance codes and core- or assembly-scale simulation tools. At the project’s outset, a document was published on the best practices and quality assurance needed to develop open-source fuel performance codes [15].

|

Fig. 5. OFFBEAT and MMM simulation results for (a) 2D discrete fuel pellets model for PCMI [16], and (b) 3D high-burnup microstructural model for fuel pellet over-fragmentation analysis [17]. |

2.3.1. The OFFBEAT/SCIANTIX codes

The OFFBEAT code [3] is a multi-dimensional fuel performance code originally developed at EPFL and PSI in Switzerland. The computational scheme refers to a cell-centered FVM to solve the nonlinear solid mechanics. This scheme is combined with a framework for thermal analysis and numerical developments concerning the treatment of the fuel/cladding gap heat transfer and contact, based on a mapping algorithm that allows the use of independent non-conformal meshes for fuel and fuel cladding. The code considers the temperature and fuel burnup dependence of material properties and is capable of modelling densification, relocation, swelling, growth, fission gas release, creep, plasticity, and other relevant fuel behavior phenomena. The OperaHPC project has already achieved new developments of the SCIANTIX code [14] and its coupling with the OFFBEAT code.

The code development activities performed within the first two years of the OperaHPC project concern the improvement of the physical models needed for an advanced description of the fuel behavior under irradiation. In the OFFBEAT code, the fuel cladding integrity assessment under PCMI or high internal pressure loading has been improved with the help of a large-strain formulation, a semi-implicit approach for thermomechanical contact, hydrogen transport, and hydride precipitation in the fuel cladding (see Refs. [18–21]). The new developments and validation of the SCIANTIX code addressed fission gas behavior in chromia-doped UO2 under restructuring process and in combination with high fuel burnup (see Refs. [22–25]). A first beta version of the OFFBEAT code has been delivered recently [26]. This version is already used in the OperaHPC project for code verification and validation and to prepare some learning databases in the framework of WP6.

2.3.2. The MMM code

The MMM code is 3D simulation tool dedicated to the solid mechanics analysis of a representative volume element of a heterogeneous material. The modelling approach is based on the MFEM-MGIS FE solver [27], enabling HPC calculations based on nonlinear mechanics. The main objective of using the MMM code is to describe the mechanical behavior of polycrystalline and porous fuel microstructures under irradiation. Three representative case studies have been defined to address the UO2 crystal viscoplastic behavior, the fuel fragmentation induced by fission gases over pressurized bubbles,and the viscoplastic behavior of an eATF ceramic-metallic fuel microstructure, respectively. Recently, a beta version of the MMM code has been delivered [28], including functionalities for the two first case studies. This version is also already used in the OperaHPC project for verification and validation before the preparation of the learning databases in the framework of WP6.

2.4. Machine learning techniques for industrial modeling

To take advantage of the advanced simulation work performed to improve the current industrial models, a computational time-reduction strategy based on machine learning techniques has been proposed in WP6. A report describing the methodology of the modelling improvement process, as well as the industrial models and fuel performance codes targeted in the project (see Fig. 6) has already been distributed to all partners [29]. This document addresses the state-of-the-art machine learning and surrogate model methods, with preliminary applications dedicated to PCMI and fission gas behavior. The first step in WP6 focused on building learning databases with the 3D simulation tools OFFBEAT and MMM developed in the project. These simulation results address both PCMI and FO phenomena consistently, with representative industrial studies of fuel element behavior targeted in WP7. At the end of the 2nd project year, the OFFBEAT simulations have started in order to acquire a detailed description of the pellet-cladding gap evolution, including a possible recovery of pellet fragment relocation after gap closure.

2.5. Representative industrial studies

The objective of this activity, carried out in WP7, is to demonstrate the capacity of 3D simulation and improved modelling for a set of representative industrial studies for PWRs and VVERs. For this, six different configurations have been defined to address questions related to state-of-the-art and eATF designs. These studies will enable the project partners to assess the fuel element behavior with improved models in fuel performance codes, such as TRANSURANUS, FINIX or CYRANO3, and also to challenge the OFFBEAT and the MMM codes in an industrial study framework. During the two first years, the activities in WP7 focused on the computation of irradiation loading history for the VVER configurations. New assessments at the core scale have been provided (see Fig. 7) to describe the nominal irradiation conditions for different fuel assembly configurations, the reactivity insertion accident (RIA) conditions with Cr-coated ATF claddings and the loss-of-coolant accident (LOCA) conditions with a large break in the cold leg.

|

Fig. 7. VVER core study to assess irradiation loading history: input data for fuel element behavior analysis [30]. |

2.6. Education & training

The large range of scientific topics in the OperaHPC project enables a comprehensive educational & training program in WP8, which touches upon basic research topics as well as industrial applications through fuel performance codes development and machine learning techniques. The project focus vis-à-vis the dissemination and exploitation of results [31] is the alignment with the EU Open Science policy, Open Access publications, open-source codes, and FAIR data management. One strength of this approach is to capitalize all project developments and results in open-source codes available for the partners, and beyond, for fuel performance codes and material communities. At the end of the 2nd year of the project, 32 publications were produced, including 13 articles in peer-reviewed journals and 19 conference presentations; moreover, beta versions of the OFFBEAT and MMM codes were uploaded to the open-source GitLab repository. In order to maximize the project impact on industrial studies, OperaHPC interacts with an End Users Group composed of industrial players in charge of the development and licensing of innovative fuels for current European reactors and in collaboration with manufacturers, utilities, and TSOs [32]. The members of the OperaHPC project End Users Group are EDF, France; EK-CER, Hungary; Framatome GmbH, Germany; TVO, Finland; Vattenfall, Sweden; Westinghouse, Sweden; and ASNR, France.

3. The SCORPION project

3.1. The need for accident-tolerant fuels (ATFs)

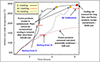

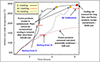

Standard fuel forms based on zirconium-based alloy (zircaloy) fuel claddings with UO2 fuels have served the nuclear power industry for a number of decades, lowering the fuel cost to less than 25% of the total cost for electricity production. However, the 2011 Fukushima Daiichi event highlighted the inherent weaknesses of these standard fuel forms during a LOCA. These weaknesses include the runaway exothermic oxidation reactions of zircaloy fuel claddings in contact with steam; such reactions can raise the core temperature to high levels (1500–1700 °C in PWRs [33]), resulting in fuel cladding failure. Fuel cladding failure leads to the release of fission products to the power plant containment, making the plant decontamination problematic and possibly leading to plant loss. The release of fission products to the containment is accompanied by hydrogen release that might lead to hydrogen explosion, containment breaching, and escape of radioactive fission products beyond the site boundary. At this stage, financial consequences include the plant loss and the remediation cost of the surrounding area; most importantly, however, both environment and society in the vicinity of the plant are harmed. ATFs are expected to enhance nuclear energy safety by surviving the loss of active cooling in the reactor core for considerably longer times during design-basis and beyond-design-basis events. The performance of candidate ATF cladding materials is assessed based on their resistance to high-temperature steam oxidation and the overall fuel cost performance [33]. Figure 8 shows the calculated temperature rise for Zr-based, stainless steel (SS), and SiC-based fuel cladding materials due to the loss of active cooling (power station blackout) in a PWR; as may be seen, only the SiC-based cladding can maintain the temperature at ∼1700 °C for a sufficiently long time after the blackout, thus enabling the potential reclaim of the power plant. The superior performance of the SiC fuel cladding is attributed to the lack of an accelerating oxidation reaction that accounts for the rapid temperature rise in the case of zircaloy and SS claddings. In case the blackout would be short-lived (< 1 h, as in the TMI-2 event), the SS cladding can also prevent fission product release to the containment and save the plant. However, longer blackouts (e.g., in the Fukushima event) cannot be addressed by either SS or Zr-based fuel claddings, resulting in fission product release to the containment and probably to the environment, if the blackout is prolonged. With respect to the economic performance of the fuel, relevant analyses [33] have indicated that the use of SiC-based claddings is associated with a small benefit ($410M) as compared to the currently used Zr-based claddings, thanks to the greater SiC neutron transparency. On the other hand, the use of SS claddings is accompanied by a yearly cost penalty of approx. $2.5B, which stems from the parasitic thermal neutron absorption of SS claddings, as compared to the more neutron-transparent zircaloy fuel claddings. The above analyses demonstrate the remarkable potential and inherent accident tolerance of SiC-based fuel claddings, justifying the already large investments in these materials on a global scale.

|

Fig. 8. Performance of different fuel claddings and consequences thereof; SS = stainless steel (adapted from [33]). |

First and foremost, innovative fuel cladding materials with true accident tolerance must demonstrate improved compatibility with steam under transient/accident conditions vis-à-vis commercial zircaloys, which undergo strong exothermic steam oxidation reactions that can lead to rapid fuel cladding failure (Fig. 8). Even though the high-temperature (1200–1600 °C) oxidation kinetics of SiC are strongly affected by composition, steam pressure, and steam velocity [34], the large global investments already made in the SiC/SiC composite ATF cladding material concept were partly motivated by the prolonged expected stability of SiC-based materials at ∼1700 °C in contact with steam (Fig. 8). These expectations were based on the exceptional refractoriness of SiC, which forms the first liquid phase at ∼2830 °C (red arrow in Fig. 9a) in its stoichiometric (SiC) and hyper-stoichiometric (i.e., SiC with excess C) compositions, according to the Si-C equilibrium phase diagram shown in Figure 9a. On the other hand, hypo-stoichiometric SiC (i.e., SiC with excess Si) forms the first liquid at 1420 °C (blue arrow in Fig. 9a). Moreover, candidate ATF cladding materials are expected to show an equally good or – if possible – better performance than zircaloys in contact with water of controlled chemistry, i.e., under nominal operation conditions. SiC forms silica (SiO2) in water, which is water-soluble, accounting for the non-negligible material losses of SiC/SiC composites during nominal operation. Silica solubility in water peaks at ∼340 °C, being 3-4 times higher for amorphous silica than for quartz [35]. The severity of this problem is reduced by the technology drivers via the deposition of a dense chemical vapor-deposited (CVD) β-SiC coating (50–500 μm-thick, depending on the material design) on SiC/SiC composite fuel claddings; the CVD SiC layer is used to limit material losses in water, sealing porous SiC/SiC composites – such as those produced by chemical vapor infiltration (CVI) of SiC fiber preforms – from in-service water ingress into the material bulk. One of the main objectives of the SCORPION (“SiC composite claddings: LWR performance optimization for nominal and accident conditions”) project [36] is the radical improvement of the compatibility of SiC with water & steam, for reasons that will be explained in the following two sections.

|

Fig. 9. (a) Si-C equilibrium phase diagram: stoichiometric & hyper-stoichiometric SiC starts melting at 2830 °C. (b) Silica (SiO2) equilibrium phase diagram: β-cristobalite melts at ∼1723 °C. (c) Schematic of the Si-C-O ternary phase system (top), and SiO2-SiC pseudo-binary phase diagram (bottom) showing gas formation above 2086 K (1813 °C); abbreviations: G = gas (vapor), CR = crystalline SiO2 (cristobalite or tridymite), LS = liquid salt, LM = liquid metal (adapted from [37]). |

3.2. SiC compatibility with steam (transient/accident LWR conditions)

SiC is typically passivated by silica (SiO2) in contact with steam, hence, under transient/accident conditions, the system of relevance is not stoichiometric SiC, but the SiC-SiO2 equilibrium (top, Fig. 9c). As shown in the SiO2-SiC phase diagram of Figure 9c, gas phase formation (SiO & CO) is predicted at temperatures higher than 2086 K (1813 °C), for the particular system studied in [37]. The formation of SiO2 on SiC/SiC composites tested in steam was confirmed by energy-dispersive X-ray spectroscopy (EDS; see Fig. 10a). The high-temperature polymorph of silica, β-cristobalite, melts at ∼1723 °C, as pinpointed by a red arrow in the SiO2 equilibrium phase diagram of Figure 9b; other silica polymorphs, such as tridymite and quartz, melt at lower temperatures. Molten silica reacts with solid SiC, producing gaseous species (SiO & CO) according to the following chemical reaction: 2SiO2(l) + SiC(s) ↔ 3SiO(g) + CO(g). This unexpected SiC/SiO2 chemical reactivity was, for the first time, observed during very high temperature steam oxidation tests performed at KIT on Westinghouse (WH) SiC/SiC composites, where the strong release of gaseous species at 1750 °C led to premature test termination (Fig. 10a). Subsequent transient steam oxidation tests performed at KIT on CEA SiC/SiC composite fuel claddings gave similar results [38]; the CEA SiC/SiC composites were tested in the framework of the H2020 IL TROVATORE project (another Euratom project dedicated to ATF cladding materials and linked to SCORPION; see Sect. 3.5). These data suggest that the formation of SiO2 must be prevented during the exposure of SiC/SiC composites to steam, in order to exploit the refractoriness of SiC at temperatures exceeding the melting point of β-cristobalite (∼1723 °C). A straightforward way to prevent the formation of SiO2 on SiC exposed to high-temperature steam is via the deposition of protective coatings on the surface of SiC/SiC composite fuel claddings; this solution is pursued in SCORPION.

|

Fig. 10. (a) Results of screening steam oxidation tests at very high temperatures, performed at KIT on WH SiC/SiC composite fuel claddings: 1600 °C, 1 h (left); 1700 °C, 1 h (middle); 1750 °C, 16 min (right). Severe damage is visible on the surface of the tube tested at 1750 °C; SEM/EDS inspection of all tube surfaces detected the formation of SiO2. (b) Transient steam oxidation test (heating rate: 10 °C/min) to 1845 °C performed at KIT on CEA SiC/SiC composite fuel claddings showed severe tube damage accompanied by a gaseous phase release. Transient tests require sealed rodlets filled with graphite susceptors for high-frequency inductive heating (c). Light optical microscopy images of metallographic cross-sections of intact (d) and damaged (e) tube areas; the latter shows the failure of the outer CVD SiC layer (adapted from [38]). |

3.3. SiC compatibility with water (nominal LWR conditions)

As already mentioned, SiC in contact with warm water forms silica (SiO2) that is water-soluble, accounting for material losses during nominal operation. Water flow accelerates such losses, whilst water chemistry plays also an important role, as standard autoclave testing of SiC/SiC composites in hydrogenated water showed better material performance than in oxygenated water, presumably due to the relative suppression of silica formation in the first case. Moreover, some of the SiC/SiC composite variants are more prone to hydrothermal corrosion than others; for example, liquid phase-sintered (LPS) SiC/SiC composites contain an amount of residual sintering additives (e.g., alumina, Al2O3, and yttria, Y2O3) that are water-soluble, increasing material losses under nominal operation conditions. Moreover, irradiation affects the hydrothermal corrosion behaviour of SiC/SiC composites; however, early irradiations of SiC/SiC composites at the Halden and MITR-II test reactors produced contradicting data that do not allow the reliable prediction of material performance. To be more precise, irradiations of SiC/SiC composites at Halden & MITR-II in PWR water at 290–300 °C to > 2 dpa have shown some materials to behave acceptably and others to fall apart. The only known case of simultaneous irradiation of different SiC/SiC composite variants (i.e., different grades of CVI & LPS SiC/SiC composites) was the 1st cycle of the BR2 irradiation campaign of the H2020 IL TROVATORE project; during this cycle, SiC/SiC composites were irradiated at a maximum temperature of 300 °C, in contact with (slowly) flowing PWR-like water, to a damage dose of ∼0.88 dpa (see also Sect. 3.5). Selected samples of this irradiation cycle will be subjected to post-irradiation examination (PIE) at JRC Karlsruhe in the framework of the SCORPION project.

Out-of-pile efforts to understand the degradation mechanisms of SiC under nominal operation conditions involve studies that employ both ion irradiation and aqueous corrosion tests to understand in-service material degradation. An interesting two-step study conducted at Kyoto University, Japan, involved the irradiation with self-ions (5.1 MeV Si2+) of masked SiC specimens, followed by autoclave testing (320 °C, 20 MPa, 168 h) [40]. This study revealed that irradiated sample areas receded by 3 μm more than non-irradiated areas (Fig. 11b), indicating that irradiation accelerates the hydrothermal degradation of SiC. Tests involving the sequential exposure of a nuclear material to degradation effects that act simultaneously in-reactor have an obvious disadvantage when compared to tests that can study these effects in a synergistic manner. A recent breakthrough in this field came with the development of the IAC (irradiation-accelerated corrosion) cell [41] at the MIBL (Michigan Ion Beam Lab) of the University of Michigan (U-M), USA. The IAC cell can perform synergistic proton irradiation/aqueous corrosion tests, thus allowing the study of fuel cladding material degradation under two of the three in-reactor stressors, i.e., corrosion & irradiation (Fig. 11a). The IAC cell uses a proton beam to irradiate samples in contact with (slowly) flowing water of controlled chemistry (Fig. 11c). Prior studies performed using this cell on other nuclear materials, such as Zry-4 (Fig. 11d) and 316L SS, have shown distinct differences in material degradation between irradiated & non-irradiated areas, shedding additional light into material degradation mechanisms [39, 42]. IAC tests were recently conducted on CVD SiC, a material used as outer protective coating of CVI SiC/SiC composite fuel claddings. These tests used 5.4 MeV protons (p+) to irradiate CVD SiC discs (Ø 3 mm, ∼50 μm-thick; same production batch) in contact with three different water chemistries, i.e., (a) 320 °C, PWR water with 3 ppm H2, (b) 320 °C, PWR water with 0.1 ppm H2, and (c) 288 °C, BWR (boiling water reactor) water with 2 ppm O2 and added H2SO4; the duration of all tests was 48 h. Three areas formed on the surface of each tested CVD SiC disc due to differences in the degradation mechanisms, i.e., proton irradiation & water radiolysis (I), water radiolysis (II), and aqueous corrosion (III) (Fig. 11e).

|

Fig. 11. (a) Factors causing the in-reactor degradation of fuel cladding materials: COR = corrosion, RDN = radiation, STR = stress. (b) A 3 μm-high step was found between unirradiated and irradiated (5.1 MeV Si2+) areas in high-purity 3C-SiC; self-ion irradiation preceded the SiC exposure to water (320 °C, 20 MPa, 168 h) [40]. (c) The IAC cell used for synergistic proton irradiation/aqueous corrosion tests on various nuclear materials. (d) Zircaloy-4 (Zry-4) subjected to proton irradiation (3.2 MeV p+; 1.1 × 10−6 dpa/s; 320 °C; 24 h) in contact with hydrogenated water (3 ppm H2) in the IAC cell. SEM inspection of the tested Zry-4 sample revealed oxide scales of ∼0.3 μm and ∼3 μm in thickness in the unirradiated and irradiated areas, respectively [39]. (e) Three areas are typically observed on the surface of disc-shaped samples subjected to synergistic proton irradiation/aqueous corrosion tests in the IAC cell. The material degradation mechanisms in these three areas are: (I) proton irradiation & water radiolysis, (II) water radiolysis, and (III) aqueous corrosion. The diameter of area (I) corresponds to the diameter of the p+ beam. |

All three IAC tests on CVD SiC (Fig. 12a) achieved a damage dose of 0.1 dpa (full-cascade SRIM calculations; SRIM = The Stopping and Range of Ions in Matter [43]) at an accumulation rate of 0.05 dpa/day versus the expected 0.025 dpa/day during the BR2 irradiation of SiC-based materials in H2020 IL TROVATORE (see Sect. 3.5). Figures 12b–12c show results of the IAC test performed at 320 °C for 48 h in contact with PWR water containing 3 ppm H2. This test was only twice faster than the BR2 irradiation in terms of damage accumulation rate but was accelerated in terms of hydrothermal corrosion; the latter has been attributed to SiC attack by water radiolysis species, mainly hydrogen ions (H+), the concentration of which was significantly increased by the fraction of the p+ beam (∼99%, according to SRIM calculations) that was transmitted through the CVD SiC sample, ending up in the volume of water in direct contact with the SiC sample surface (see Fig. 12a). It should be noted that the batch of CVD SiC (supplied by GA-EMS) irradiated in the IAC test cell in three different water chemistries had been intentionally produced with a high density of defects, such as SFs and intricate dislocation networks, to study the effect of processing-induced defects on material performance. The as-fabricated CVD SiC consisted of columnar SiC grains growing quasi-parallel to each other and perpendicular to the (sacrificial) substrate and containing numerous SFs, which appear as fine lines perpendicular to the direction of grain growth (Fig. 12c). The CVD SiC sample tested at 320 °C for 48 h in PWR water with 3 ppm H2 appeared preferentially attacked by water radiolysis species (esp. H+) at GBs & SFs (Fig. 12d). These findings support the rather recent ab initio molecular dynamics (MD) simulations of corrosion effects at the SiC/water interface, which revealed that the scission of the Si-C bonds by hydrogen species is an important step of the hydrothermal degradation process of SiC [44]. The contribution of the hydrogen scission reaction to the hydrothermal degradation of SiC becomes more important in LWR service environments, where water radiolysis provides continuously hydrogen ions (H+) that are capable of attacking nanometric SiC ‘defects’, such as GBs & SFs, due to their small size (van der Waals radius: 120 pm). Obviously, the scission of Si-C bonds by H+ at GBs & SFs creates new internal interfaces in bulk SiC that are very susceptible to oxidation, producing water-soluble oxidation species such as silicic acid (Si(OH)4) & SiO2 and increasing greatly the material losses under nominal operation conditions.

|

Fig. 12. (a) Setup used for synergistic proton irradiation/aqueous corrosion testing of CVD SiC discs in the IAC cell; the p+ beam diameter was 1.5 mm. (b) A CVD SiC disc (48 μm-thick) appeared perforated after testing in the IAC cell (see central hole). The test conditions were: 5.4 MeV p+, 320 °C, 48 h, hydrogenated PWR water (3 ppm H2). (c) HAADF STEM image of as-fabricated CVD SiC made of columnar SiC grains. Yellow arrows indicate the growth direction of neighbouring columnar SiC grains. The dashed white line marks the termination of the columnar SiC grains, which coincides with the top surface of the CVD SiC coating. The SiC grains contain a high density of stacking faults, SFs, which are better visible in the inset atomic-resolution HAADF STEM image. (d) After IAC testing, the SiC grains appeared preferentially attacked at grain boundaries (GBs) and SFs. (e) SEM micrographs of bulk yttrium aluminium garnet (Y3Al5O12; YAG) produced by pressureless sintering (left) and bulk SiC GB engineered with YAG (right). (f) A bulk YAG disc (50 μm-thick) appeared integral after IAC testing at identical conditions as the CVD SiC disc of Fig. 12b. The radiation-assisted hydrothermal degradation of YAG was limited to mild GB etching. |

3.4. Improving the SiC compatibility with water & steam in SCORPION

The experimental data presented in Sections 3.2 & 3.3 show that SiC/SiC composite ATF cladding materials intended for use in Gen-II/III LWRs need protective outer coatings that inhibit material losses in water caused by the formation of water-soluble species such as Si(OH)4 & SiO2 (nominal operation conditions), and prevent the formation of SiO2 in steam, as SiO2 melts at ∼1723 °C, reacting with SiC and forming gaseous species such as SiO & CO (transient/accident conditions). The development of appropriate coating materials for SiC/SiC composites is one of the two main avenues explored in SCORPION to improve the compatibility of SiC with water & steam. One of the candidate coating materials is yttrium aluminium garnet (Y3Al5O12; YAG). YAG is a refractory ceramic (melting point = 1942 °C; density = 4.56 g/cm3; CTE = 6.14 × 10−6 °C−1) that has exhibited excellent compatibility with both water & steam. In SCORPION, quasi phase-pure YAG has been synthesised at KU Leuven both by pressureless sintering (1150–1600 °C, 4 h, air; Fig. 12e left) and pulsed electric current sintering (1350–1550 °C, 10 min, 30 MPa, vacuum). YAG supplied by KU Leuven has been tested (a) at CEA in autoclave (360 °C, 187 bar, 28 days, PWR water containing 1000 ppm B & 2 ppm Li), showing a negligible mass change of −0.003%, and (b) at KIT in steam (1600 °C, 1 h, heating/cooling at 10 °C/min), exhibiting again a very small weight change of −0.015%. Furthermore, YAG has been subjected to synergistic proton irradiation/aqueous corrosion testing in the IAC cell (U-M), at identical conditions (i.e., 5.4 MeV p+, 320 °C, 48 h, PWR water with 3 ppm H2) as the CVD SiC shown in Figures 12b–12d. The performance of YAG (Fig. 12f) was much better than the performance of CVD SiC that emerged perforated in area I (Fig. 12b) from the IAC cell, i.e., the consumption rate of the particular batch of CVD SiC under radiation-assisted hydrothermal corrosion was ≥1 μm/h. On the other hand, YAG exhibited only mild GB etching in areas I & II after IAC testing (Fig. 12f); moreover, testing resulted in some porosity due to the dissolution of parasitic alumina (Al2O3) stemming from material processing (Fig. 12f). Materials intended to be used as protective coatings for SiC/SiC composite ATF claddings should not contain water-soluble parasitic phases such as Al2O3 & SiO2.

The second approach systematically investigated in SCORPION to improve the compatibility of SiC with high-temperature, high-pressure water involves the GB engineering of SiC with compounds that exhibit excellent resistance to hydrothermal corrosion and high-temperature steam oxidation. The decoration of GBs in bulk SiC ceramics with compounds that can hinder the preferred ingress of water radiolysis species into these inherent material ‘defects’ is expected to delay the (radiation-assisted) hydrothermal ageing of SiC-based materials, thus drastically reducing material losses during nominal operation. The incentive behind this approach is the fact that GB engineering has been shown to improve the hydrothermal stability of 3 mol% yttria-stabilised tetragonal zirconia polycrystalline (3Y-TZP) ceramics used for dental restoration [45]. Adding select dopants that segregate preferentially at GBs improves the performance of these ceramics, and the degree of improvement increases with the radius of the dopant cation (La3+ > Nd3+ < Al3+), probably due to the change in the GB diffusivity of water species (esp. OH−), which is held responsible for the hydrothermal ageing of zirconia (ZrO2). The microstructure of a bulk SiC GB engineered with YAG (Y3Al5O12) is shown in Figure 12e (right image); this ceramic material has been synthesized at KU Leuven by spark plasma sintering (2000 °C, 10 min, 28 MPa, vacuum). Different grades of GB engineered SiC ceramics are currently being studied in SCORPION vis-à-vis their suitability for the ATF cladding application, systematically testing their performance in water (autoclaves, CEA) & high-temperature steam (BOX furnace, KIT), under in situ ion irradiation (MIAMI-2 facility, University of Huddersfield), and under synergistic proton irradiation/aqueous corrosion (IAC cell, U-M). The successful GB engineering of SiC with various compounds that exhibit excellent compatibility with both water & steam is considered an important technical and scientific milestone of the SCORPION project.

3.5. Linked international research collaborations on ATFs

SCORPION is linked with two international research projects on innovative ATF cladding materials, including the SiC/SiC composite ATF cladding material concept, the radical performance optimisation of which is the main objective of SCORPION. These two international research projects are: H2020 IL TROVATORE (“Innovative cladding materials for advanced accident-tolerant energy systems”) & I-NERI US/EURATOM PERSEUS (“Advanced PIE of accident-tolerant fuel claddings neutron-irradiated in the BR2 test reactor”). H2020 IL TROVATORE (Grant Agreement No. 740415) is an international collaboration between Europe, the USA, and Japan, and the largest (30 partners) ongoing programme in the World on ATF cladding materials. H2020 IL TROVATORE combines seamlessly academic excellence with strong industrial support, while also engaging directly or indirectly standardisation bodies (e.g., AFNOR, ISO), nuclear safety regulatory authorities (e.g., Bel V), and important organisations that are actively striving for safer nuclear energy (e.g., IAEA, JAEA, US-DOE), thus maximising the EU added value and its global impact. The main focus of H2020 IL TROVATORE is the optimisation and validation of innovative ATF cladding material concepts (coated zircaloys, SiC/SiC composites, and ODS-FeCrAl alloys) in industrially relevant conditions, i.e., under neutron irradiation in PWR-like water. This H2020 IL TROVATORE irradiation campaign is performed in the BR2 test reactor at SCK CEN (Belgian Nuclear Research Centre) and targets the co-irradiation of different candidate ATF cladding material concepts and variants thereof (Tmax = 320 ± 20 °C; damage accumulation rate = 25 × 10−3 dpa/day, calculated for Fe; PWR-like water; expected damage dose after 3 cycles ≈2.15 dpa, calculated for Fe). The MISTRAL-N irradiation rig is designed to carry 3 needles, each one of which can be loaded with up to 17 ATF cladding rodlets (standard length: L ≈ 30 mm; adjustable length). The 1st cycle of the H2020 IL TROVATORE BR2 irradiation campaign included two needles fully loaded with SiC-based rodlets from various suppliers (WH, Toshiba, GA-EMS, ORNL = Oak Ridge National Lab, CEA, Kyoto University).

I-NERI US/EURATOM PERSEUS is an international collaboration endorsed by both European Commission (Euratom) & US Department of Energy (US-DOE) with the main aim to conduct in-depth PIE on select ATF claddings & joints irradiated in the BR2 test reactor within H2020 IL TROVATORE. I-NERI (International Nuclear Energy Research Initiative) projects foster US/EURATOM collaborations on topics of mutual interest for both parties, providing a legal framework for collaborative R&D activities between partners contributing with their own resources or with funds secured on competitive basis to make such collaborations possible. The I-NERI PERSEUS partners are: H2020 IL TROVATORE, PNNL (Pacific Northwest National Lab), INL (Idaho National Lab), JRC Karlsruhe, U-M, WH, and GA-EMS (see Fig. 13). The advanced PIE of BR2-irradiated materials employs cutting-edge materials characterization techniques at PNNL, INL & JRC Karlsruhe, and is expected to yield key data on reactor-relevant ATF cladding material performance, contributing to the understanding of material degradation mechanisms, and aiding further material optimization by providing feedback to the ATF technology drivers. Figure 13 depicts the link between H2020 IL TROVATORE & I-NERI PERSEUS: the former foresees the irradiation of different ATF cladding material concepts in the BR2 test reactor, whereas the latter focuses mainly on the advanced PIE of the BR2-irradiated ATF claddings.

|

Fig. 13. Interconnection of H2020 IL TROVATORE & I-NERI US/EURATOM PERSEUS: the former targets the optimization of ATF cladding material concepts, culminating in the irradiation of the best-performing candidate materials in the BR2 research reactor, whereas the latter focuses on the advanced PIE of BR2-irradiated materials. The I-NERI PERSEUS partners are indicated using blueblue characters: H2020 IL TROVATORE, PNNL, INL, JRC Karlsruhe, U-M, WH, and GA-EMS. |

To achieve its S&T objectives, the SCORPION project involves 11 beneficiaries from Europe (IIT, Italy; KU Leuven, Belgium; RWTH Aachen University, Germany; KIT, Germany; Friedrich-Alexander University Erlangen-Nürnberg, Germany; GTT mbH, Germany; Linköping University, Sweden; CEA, France; POLITO, Italy; JRC Karlsruhe, Belgium; x-nano Srl, Italy), 1 beneficiary from the USA (University of Michigan), 1 beneficiary from Japan (Kyoto University), 2 associated partners from the UK (Oxford University; University of Huddersfield), and 1 associated partner from Switzerland (PSI). The S&T progress of the SCORPION project is periodically assessed by the members of the External Expert Advisory Committee (EEAC), who are renowned experts from (a) industries with vested interests in SiC/SiC composite ATF cladding material concepts (Westinghouse Electric Company LLC; General Atomics-Electromagnetic Systems; Framatome; Rolls-Royce; NGS Advanced Fibers Co., Ltd), (b) US National Laboratories with leading expertise in the testing, irradiation, and PIE of SiC/SiC composite ATF claddings (PNNL; INL; ORNL), and (c) the IAEA (International Atomic Energy Authority).

4. Conclusions

This article provides a high-level overview of the scope and midterm achievements of the Euratom-funded OperaHPC & SCORPION projects. Even though both projects are dedicated to accident-tolerant fuels (ATFs), OperaHPC focuses primarily on the simulation of the in-pile behavior of fuel elements, as implemented in fuel performance codes that are the cornerstones of fuel licensing, in conjunction with fuel data collected from neutron irradiation campaigns. Considering that neutron irradiations of novel nuclear materials are both costly and time-consuming, the OperaHPC project objectives have been carefully defined to contribute to fuel performance code qualification using advanced simulation tools with physically based modelling and high-performance computing (HPC) capabilities. The main motivation behind this plan is to address the challenge of reducing the licensing period needed for the qualification of enhanced ATFs (eATFs) by accelerating the transfer of know-how from the R&D stage to the end-users of fuel performance codes. It is also worthwhile noting that one of the industrial studies of OperaHPC is the Cr-coated zircaloy fuel cladding, which is the ‘near-term’ ATF cladding material concept endorsed by both Westinghouse & Framatome and expected to be deployed to market rather soon (estimated deployment timescale: 2026–2028). On the other hand, SCORPION is a ‘hardcore’ experimental project targeting the radical performance optimization – through a multiscale material tailoring approach – of the ‘revolutionary’ SiC/SiC composite ATF cladding material concept, the market deployment of which is anticipated the earliest in the next 5-10 years. However, specific predictive modelling activities in SCORPION employ similar simulation tools as OperaHPC; for example, the effect of void swelling on the thermal conductivity of irradiated SiC will be simulated in SCORPION with the 2D fuel performance code Falcon in conjunction with the 3D OFFBEAT code also developed and employed in OperaHPC. The above demonstrate that even though OperaHPC & SCORPION appear to focus on different R&D activities, with the former being simulation-oriented and the latter experiment-enabled, both projects address different but important aspects of ATF qualification and licensing. The complementary learnings and insights achieved by these two projects are, thus, expected to aid the expedited deployment of ATFs designed and developed to enhance nuclear energy safety on a global scale.

Acknowledgments

The IAC tests and post-test analysis of CVD SiC samples fall within the framework of the I-NERI PERSEUS project. The CVD SiC samples were supplied by General Atomics-Electromagnetic Systems (GA-EMS). Post-test analysis of the CVD SiC samples tested in the IAC cell was conducted at U-M and PNNL. The SiC/SiC composites subjected to very high temperature steam oxidation tests at KIT were supplied by Westinghouse Electric Company LLC (WH), GA-EMS, and CEA. The YAG bulk ceramics tested in autoclave at CEA, high-temperature steam at KIT, and synergistic proton irradiation/aqueous corrosion testing in the IAC cell of U-M were supplied by the Department of Materials Engineering (MTM) of the KU Leuven.

As this article aims to provide a high-level overview of the scope and status of the OperaHPC and SCORPION projects, it is impossible to include all material suppliers and data contributors in the authors’ list. In an attempt to correct this, some of the contributors are identified here. B.M. would like to acknowledge M. Bertolus of CEA; R. Largenton of EDF; J. Heikinheimo of VTT; A. Scolaro of EPFL; L. Luzzi of POLIMI; R. Lo Frano of UNIPI; M. Zilly of Framatome GmbH; and S. De Grandis of SINTEC for their support in coordinating the OperaHPC project, as well as all project contributors to the results presented in this article. K.L. would like to acknowledge E.J. Lahoda & L. Czerniak of WH; C.P. Deck & S. Gonderman of GA-EMS; C. Lorrette, J. Braun & C. Sauder of CEA; M. Grosse & M. Steinbrueck of KIT; S. Huang & J. Vleugels of KU Leuven; R.D. Hanbury, K. Sun, P. Wang & G.S. Was of U-M; and K.H. Yano, J.A. Silverstein, S.L. Riechers & R.L. Oelrich of PNNL.

Funding

Both OperaHPC and SCORPION projects have been co-funded by the Horizon-Euratom Research & Training Programme 2021-2025, OperaHPC under Grant Agreement No 101061453 and SCORPION under Grant Agreement No 101059511. The H2020 IL TROVATORE project has been co-funded by the Euratom Research & Training Programme 2014-2018 under Grant Agreement No 740415. The IAC cell tests on CVD SiC were funded by US-DOE, Office of Nuclear Energy under DOE Idaho Operations Office Contract No DE-AC07-051D14517. The post-test analysis of the CVD SiC samples subjected to synergistic proton irradiation/aqueous corrosion in the IAC cell have been co-funded by WH, PNNL, and H2020 IL TROVATORE.

Conflicts of interest

The authors have no conflicts of interest to disclose.

Data availability statement

Data associated with project results presented in this article cannot be disclosed yet until the findings of the OperaHPC and SCORPION projects have either been published under the Open Access publication scheme or protected via patent applications.

Author contribution statement

Conceptualization, M.B. and K.L.; Data Curation, M.B. and K.L.; Writing – Original Draft Preparation, M.B. and K.L.; Writing – Review & Editing, M.B. and K.L.; Project Coordination, M.B. and K.L.; Funding Acquisition, M.B. and K.L.

References

- OperaHPC project website: https://www.operahpc.eu/ [Google Scholar]

- P. Van Uffelen, G. Pastore, 2.13 – in Oxide Fuel Performance Modeling and Simulation, Comprehensive Nuclear Materials, edited by R.J.M. Konings, R.E. Stoller, 2nd edn. (Elsevier, 2020), Vol. 2, pp. 363–416, https://doi.org/10.1016/B978-0-12-803581-8.11693-5 [Google Scholar]

- A. Scolaro, I. Clifford, C. Fiorina, A. Pautz, The OFFBEAT multi-dimensional fuel behavior solver, Nucl. Eng. Des. 358, 110416 (2020), https://doi.org/10.1016/j.nucengdes.2019.110416 [Google Scholar]

- P. Van Uffelen, J. Hales, W. Li, G. Rossiter, R. Williamson, A review of fuel performance modelling, J. Nucl. Mater. 516, 373 (2019), https://doi.org/10.1016/j.jnucmat.2018.12.037 [Google Scholar]

- C. Introïni, I. Ramière, J. Sercombe, B. Michel, T. Helfer, J. Fauque, ALCYONE: The fuel performance code of the PLEIADES platform dedicated to PWR fuel rods behavior, Ann. Nucl. Energy 207, 110711 (2024), https://doi.org/10.1016/j.anucene.2024.110711 [Google Scholar]

- M. Lainet, B. Michel, J.-C. Dumas, M. Pelletier, I. Ramière, GERMINAL, a fuel performance code of the PLEIADES platform to simulate the in-pile behaviour of mixed oxide fuel pins for sodium-cooled fast reactors, J. Nucl. Mater. 516, 30 (2019), https://doi.org/10.1016/j.jnucmat.2018.12.030 [Google Scholar]

- J. Noirot, Y. Pontillon, S. Yagnik, J.A. Turnbull, Post-irradiation examinations and high-temperature tests on undoped large-grain UO2 discs, J. Nucl. Mater. 462, 77 (2015), https://doi.org/10.1016/j.jnucmat.2015.03.008 [Google Scholar]

- H. Fuentes, A. Socié, C. Colin, Design of a compression mechanical testing device for irradiated fuel at high temperature, Milestone MS2 document of the OperaHPC project. [Google Scholar]

- C. Onofri, Results of TEM and SEM characterization of irradiated fuel before mechanical testing. OperaHPC Public (PU) project deliverable D1.1 (2024), https://www.operahpc.eu/documents-and-results/ [Google Scholar]

- J.-E. Suchorski, A. Pivano, J. Amodeo, Screw dislocation core structure and mobility in UO2, The 11th International Conference on Multiscale Materials Modeling (MMM11), 22-27 September 2024, Prague, Czech Republic, https://mmm11.ipm.cz [Google Scholar]

- L. Dixon, M. Rushton, The determination of fracture toughness in UO2 using classical Molecular Dynamics, Second annual meeting of the OperaHPC Euratom project, 20-21 November 2024, Cordoba, Spain [Google Scholar]

- P. Aragón, F. Feria, L.E. Herranz, A. Schubert, P. Van Uffelen, Fuel performance modelling of Cr-coated Zircaloy cladding under DBA/LOCA conditions, Ann. Nucl. Energy 211, 110950 (2025), https://doi.org/10.1016/j.anucene.2024.110950 [Google Scholar]

- G. Latu, T. Helfer, S. Bernaud, G. Folzan, MFEM-MGIS-MFRONT, A HPC mini-application targeting nonlinear thermo-mechanical simulations of nuclear fuels at mesoscale, TMDA Open-Source Modelling and Simulation Tools for Nuclear Reactors, IAEA Conferences, https://conferences.iaea.org/event/247/contributions/20551/attachments/10969/16119/Abstract_Latu.docx [Google Scholar]

- D. Pizzocri, T. Barani, L. Luzzi, SCIANTIX: A new open source multi-scale code for fission gas behaviour modelling designed for nuclear fuel performance codes, J. Nucl. Mater.s 532, 152042 (2020), https://doi.org/10.1016/j.jnucmat.2020.152042 [Google Scholar]

- A. Scolaro, B. Michel, G. Latu, D. Pizzocri, L. Luzzi, I. Clifford, Best practices and QA protocols for code development. OperaHPC PU project deliverable D4.1 (2023), https://www.operahpc.eu/documents-and-results/ [Google Scholar]

- I. Guénot-Delahaie et al., Task 5.1 – Update on the verification status of OperaHPC tools caried out and remaining work towards D5.1, Second annual meeting of the OperaHPC Euratom project, 20-21 November 2024, Cordoba, Spain [Google Scholar]

- T. Barani et al., Modelling over-fragmentation induced by pressurized bubbles into a brittle material by MMM, Second annual meeting of the OperaHPC Euratom project, 20-21 November 2024, Cordoba, Spain [Google Scholar]

- L. Verma, I. Clifford, P. Konarski, A. Scolaro, H. Ferroukhi, OFFBEAT V&V studies for REBEKA tests on cladding ballooning and burst during LOCA conditions, Ann. Nucl. Energy 208, 110773 (2024), https://doi.org/10.1016/j.anucene.2024.110773 [Google Scholar]

- M. Reymond, J. Sercombe, A. Scolaro, Investigation of the PCMI failure of pre-hydrided Zy-4 cladding during Reactivity Initiated Accidents with ALCYONE and OFFBEAT fuel performance codes, Nucl. Eng. Des. 427, 113430 (2024), https://doi.org/10.1016/j.nucengdes.2024.113430 [Google Scholar]

- E.L. Brunetto, A. Scolaro, C. Fiorina, A. Pautz, Extension of the OFFBEAT fuel performance code to finite strains and validation against LOCA experiments, Nucl. Eng. Des. 406, 112232 (2023), https://doi.org/10.1016/j.nucengdes.2023.112232 [Google Scholar]

- L. Verma, I. Clifford, H. Ferroukhi, A. Scolaro, Extending the validation database of OFFBEAT fuel performance code for LOCA scenarios, TOPFUEL 2024, 29 September - 3 October 2024, Grenoble, France. https://www.operahpc.eu/wp-content/uploads/2024/11/3.Verma_et_al_TopFuel2024_Final.pdf [Google Scholar]

- G. Zullo, A. Scolaro, T. Barani, D. Pizzocri, Two-phase modelling for fission gas sweeping in restructuring nuclear oxide fuel, Nucl. Eng. Des. 429, 113602 (2024), https://doi.org/10.1016/j.nucengdes.2024.113602 [Google Scholar]

- G. Zullo, D. Pizzocri, A. Scolaro, P. Van Uffelen, F. Feria, L.E. Herranz, L. Luzzi, Integral-scale validation of the SCIANTIX code for Light Water Reactor fuel rods, J. Nucl. Mater. 601, 155305 (2024), https://doi.org/10.1016/j.jnucmat.2024.155305 [Google Scholar]

- G. Nicodemo, G. Zullo, F. Cappia, P. Van Uffelen, A. De Lara, L. Luzzi, D. Pizzocri, Chromia-doped UO2 fuel: An engineering model for chromium solubility and fission gas diffusivity, J. Nucl. Mater. 601, 155301 (2024), https://doi.org/10.1016/j.jnucmat.2024.155301 [Google Scholar]

- G. Zullo, D. Pizzocri, L. Luzzi, The SCIANTIX code for fission gas behaviour: Status, upgrades, separate-effect validation, and future developments, J. Nucl. Mater. 587, 154744 (2023), https://doi.org/10.1016/j.jnucmat.2023.154744 [Google Scholar]

- Preliminary (beta) version of the new OFFBEAT developments, GitLab repository: https://gitlab.com/foam-for-nuclear/offbeat [Google Scholar]

- T. Helfer et al., MFEM/MGIS, a HPC mini-application targeting nonlinear thermo-mechanical simulations of nuclear fuels at mesoscale, The Journal of Open Source Software, (n.d.)., Retrieved 22 November 2024 from: https://joss.theoj.org/papers/8033479e79b6f2a12d81ad676919bb2b [Google Scholar]

- Preliminary (beta) version of the new MMM developments, GitLab repository: https://github.com/rprat-pro/mm-opera-hpc/ [Google Scholar]

- R. Lo Frano, S.A. Cancemi, L. Giaccardi, P. Van Uffelen, S. Gianfelici, T. Barani, D. Pizzocri, R. Largenton, M. Povilaitis, F. Feira, L. Caveglia Curtil, Numerical and mathematical approaches for computation time reduction, OperaHPC PU deliverable D6.1 (2024), https://www.operahpc.eu/documents-and-results/ [Google Scholar]

- M. Zilly, Simulation of fuel element behaviour in operating and accidental transient conditions, Second annual meeting of the OperaHPC Euratom project, 20-21 November 2024, Cordoba, Spain [Google Scholar]

- B. Michel, S. De Grandis, Plan for the Exploitation and Dissemination of Results, OperaHPC PU deliverable D8.2 (2023), https://www.operahpc.eu/documents-and-results/ [Google Scholar]

- B. Michel, M. Bertolus, Minutes of the first End User Group meeting, OperaHPC PU deliverable D8.5 (2024), https://www.operahpc.eu/documents-and-results/ [Google Scholar]

- E.J. Lahoda, L. Hallstadius, F. Boylan, S. Ray, What should be the objective of accident tolerant fuel?, Trans. – Am. Nucl. Soc. 110, 733 (2014) [Google Scholar]

- P.A. Mouche, K.A. Terrani, Steam pressure and velocity effects on high temperature silicon carbide oxidation, J. Am. Ceram. Soc. 103, 2062 (2020), https://ceramics.onlinelibrary.wiley.com/doi/10.1111/jace.16834 [Google Scholar]

- R.O. Fournier, J.J. Rowe, The solubility of amorphous silica in water at high temperatures and high pressures, Am. Mineral. 62, 1052 (1977) [Google Scholar]

- SCORPION project website: https://projectscorpion.eu [Google Scholar]

- S. Morris, T. Hawkins, P. Foy, C. McMillan, J. Fan, L. Zhu, R. Stolen, R. Rice, J. Ballato, Reactive molten core fabrication of silicon optical fiber, Opt. Mater. Express 1, 1141 (2011), https://doi.org/10.1364/OME.1.001141 [Google Scholar]

- M. Steinbrueck, M. Grosse, U. Stegmaier, J. Braun, C. Lorrette, Oxidation of silicon carbide composites for nuclear applications at very high temperatures in steam, Coatings 12, 875 (2022), https://doi.org/10.3390/coatings12070875 [Google Scholar]

- P. Wang, G.S. Was, Oxidation of Zircaloy-4 during in situ proton irradiation and corrosion in PWR primary water, J. Mater. Res. 30, 1335 (2015), https://doi.org/10.1557/jmr.2014.408 [Google Scholar]

- S. Kondo, S. Mouri, Y. Hyodo, T. Hinoki, F. Kano, Role of irradiation-induced defects on SiC dissolution in hot water, Corrosion Sci. 112, 402 (2016), https://doi.org/10.1016/j.corsci.2016.08.007 [Google Scholar]

- S.S. Raiman, A. Flick, O. Toader, P. Wang, N.A. Samad, Z. Jiao, G.S. Was, A facility for studying irradiation accelerated corrosion in high temperature water, J. Nucl. Mater. 451, 40 (2014), https://doi.org/10.1016/j.jnucmat.2014.03.022 [Google Scholar]

- S.S. Raiman, D.M. Bartels, G.S. Was, Radiolysis driven changes to oxide stability during irradiation-corrosion of 316L stainless steel in high temperature water, J. Nucl. Mater. 493, 40 (2017), https://doi.org/10.1016/j.jnucmat.2017.05.042 [Google Scholar]

- J.F. Ziegler, M.D. Ziegler, J.P. Biersack, SRIM – The stopping and range of ions in matter (2010), Nucl. Instrum. Methods Phys. Res. Sect. B: Beam Interact. Mater. At. 268, 1818 (2010), https://doi.org/10.1016/j.nimb.2010.02.091 [Google Scholar]

- J. Xi, C. Liu, D. Morgan, I. Szlufarska, Deciphering water-solid reactions during hydrothermal corrosion of SiC, Acta Mater. 209, 116803 (2021), https://doi.org/10.1016/j.actamat.2021.116803 [Google Scholar]

- F. Zhang, K. Vanmeensel, M. Batuk, J. Hadermann, M. Inokoshi, B. Van Meerbeek, I. Naert, J. Vleugels, Highly-translucent, strong and aging-resistant 3Y-TZP ceramics for dental restoration by grain boundary segregation, Acta Biomater. 16, 215 (2015), https://doi.org/10.1016/j.actbio.2015.01.037 [Google Scholar]

Cite this article as: Bruno Michel, Konstantina Lambrinou. OperaHPC & SCORPION: accelerated optimization of advanced fuels for Gen-II/III reactors via the synergy of high-performance computing with multiscale material engineering, EPJ Nuclear Sci. Technol. 11, 43 (2025). https://doi.org/10.1051/epjn/2025040

All Figures

|

Fig. 1. Multi-physics computational scheme used in fuel performance codes. |

| In the text | |

|

Fig. 2. Schematic diagram and computer-assisted design of the mechanical device used for creep tests on irradiated fuels [8]. |

| In the text | |

|

Fig. 3. Characterization of the dislocations induced by irradiation in the samples before the mechanical creep test. The fuel burnups of 13 GWj/tM and 37 GWj/tM correspond to the total energy produced per unit volume of fuel during one cycle and two cycles, respectively [9]. |

| In the text | |

|

Fig. 4. (a) Screw dislocation mobility in UO2 [10]. (b) UO2 phase change ahead of the tip of a crack propagating under tension [11]. |

| In the text | |

|

Fig. 5. OFFBEAT and MMM simulation results for (a) 2D discrete fuel pellets model for PCMI [16], and (b) 3D high-burnup microstructural model for fuel pellet over-fragmentation analysis [17]. |

| In the text | |

|

Fig. 6. Model improvement process using 3D simulations and machine learning techniques [29]. |

| In the text | |

|

Fig. 7. VVER core study to assess irradiation loading history: input data for fuel element behavior analysis [30]. |

| In the text | |

|

Fig. 8. Performance of different fuel claddings and consequences thereof; SS = stainless steel (adapted from [33]). |

| In the text | |

|

Fig. 9. (a) Si-C equilibrium phase diagram: stoichiometric & hyper-stoichiometric SiC starts melting at 2830 °C. (b) Silica (SiO2) equilibrium phase diagram: β-cristobalite melts at ∼1723 °C. (c) Schematic of the Si-C-O ternary phase system (top), and SiO2-SiC pseudo-binary phase diagram (bottom) showing gas formation above 2086 K (1813 °C); abbreviations: G = gas (vapor), CR = crystalline SiO2 (cristobalite or tridymite), LS = liquid salt, LM = liquid metal (adapted from [37]). |

| In the text | |

|

Fig. 10. (a) Results of screening steam oxidation tests at very high temperatures, performed at KIT on WH SiC/SiC composite fuel claddings: 1600 °C, 1 h (left); 1700 °C, 1 h (middle); 1750 °C, 16 min (right). Severe damage is visible on the surface of the tube tested at 1750 °C; SEM/EDS inspection of all tube surfaces detected the formation of SiO2. (b) Transient steam oxidation test (heating rate: 10 °C/min) to 1845 °C performed at KIT on CEA SiC/SiC composite fuel claddings showed severe tube damage accompanied by a gaseous phase release. Transient tests require sealed rodlets filled with graphite susceptors for high-frequency inductive heating (c). Light optical microscopy images of metallographic cross-sections of intact (d) and damaged (e) tube areas; the latter shows the failure of the outer CVD SiC layer (adapted from [38]). |

| In the text | |

|

Fig. 11. (a) Factors causing the in-reactor degradation of fuel cladding materials: COR = corrosion, RDN = radiation, STR = stress. (b) A 3 μm-high step was found between unirradiated and irradiated (5.1 MeV Si2+) areas in high-purity 3C-SiC; self-ion irradiation preceded the SiC exposure to water (320 °C, 20 MPa, 168 h) [40]. (c) The IAC cell used for synergistic proton irradiation/aqueous corrosion tests on various nuclear materials. (d) Zircaloy-4 (Zry-4) subjected to proton irradiation (3.2 MeV p+; 1.1 × 10−6 dpa/s; 320 °C; 24 h) in contact with hydrogenated water (3 ppm H2) in the IAC cell. SEM inspection of the tested Zry-4 sample revealed oxide scales of ∼0.3 μm and ∼3 μm in thickness in the unirradiated and irradiated areas, respectively [39]. (e) Three areas are typically observed on the surface of disc-shaped samples subjected to synergistic proton irradiation/aqueous corrosion tests in the IAC cell. The material degradation mechanisms in these three areas are: (I) proton irradiation & water radiolysis, (II) water radiolysis, and (III) aqueous corrosion. The diameter of area (I) corresponds to the diameter of the p+ beam. |

| In the text | |

|

Fig. 12. (a) Setup used for synergistic proton irradiation/aqueous corrosion testing of CVD SiC discs in the IAC cell; the p+ beam diameter was 1.5 mm. (b) A CVD SiC disc (48 μm-thick) appeared perforated after testing in the IAC cell (see central hole). The test conditions were: 5.4 MeV p+, 320 °C, 48 h, hydrogenated PWR water (3 ppm H2). (c) HAADF STEM image of as-fabricated CVD SiC made of columnar SiC grains. Yellow arrows indicate the growth direction of neighbouring columnar SiC grains. The dashed white line marks the termination of the columnar SiC grains, which coincides with the top surface of the CVD SiC coating. The SiC grains contain a high density of stacking faults, SFs, which are better visible in the inset atomic-resolution HAADF STEM image. (d) After IAC testing, the SiC grains appeared preferentially attacked at grain boundaries (GBs) and SFs. (e) SEM micrographs of bulk yttrium aluminium garnet (Y3Al5O12; YAG) produced by pressureless sintering (left) and bulk SiC GB engineered with YAG (right). (f) A bulk YAG disc (50 μm-thick) appeared integral after IAC testing at identical conditions as the CVD SiC disc of Fig. 12b. The radiation-assisted hydrothermal degradation of YAG was limited to mild GB etching. |

| In the text | |

|

Fig. 13. Interconnection of H2020 IL TROVATORE & I-NERI US/EURATOM PERSEUS: the former targets the optimization of ATF cladding material concepts, culminating in the irradiation of the best-performing candidate materials in the BR2 research reactor, whereas the latter focuses on the advanced PIE of BR2-irradiated materials. The I-NERI PERSEUS partners are indicated using blueblue characters: H2020 IL TROVATORE, PNNL, INL, JRC Karlsruhe, U-M, WH, and GA-EMS. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.