Fig. 12.

Download original image

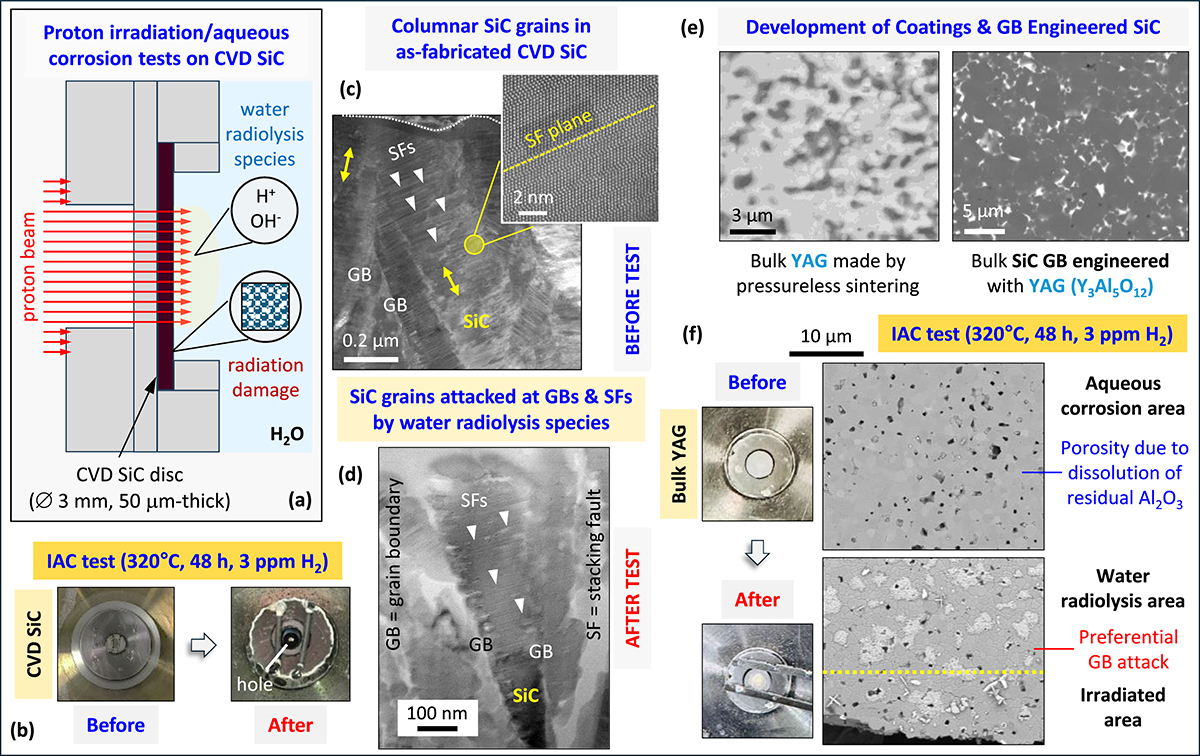

(a) Setup used for synergistic proton irradiation/aqueous corrosion testing of CVD SiC discs in the IAC cell; the p+ beam diameter was 1.5 mm. (b) A CVD SiC disc (48 μm-thick) appeared perforated after testing in the IAC cell (see central hole). The test conditions were: 5.4 MeV p+, 320 °C, 48 h, hydrogenated PWR water (3 ppm H2). (c) HAADF STEM image of as-fabricated CVD SiC made of columnar SiC grains. Yellow arrows indicate the growth direction of neighbouring columnar SiC grains. The dashed white line marks the termination of the columnar SiC grains, which coincides with the top surface of the CVD SiC coating. The SiC grains contain a high density of stacking faults, SFs, which are better visible in the inset atomic-resolution HAADF STEM image. (d) After IAC testing, the SiC grains appeared preferentially attacked at grain boundaries (GBs) and SFs. (e) SEM micrographs of bulk yttrium aluminium garnet (Y3Al5O12; YAG) produced by pressureless sintering (left) and bulk SiC GB engineered with YAG (right). (f) A bulk YAG disc (50 μm-thick) appeared integral after IAC testing at identical conditions as the CVD SiC disc of Fig. 12b. The radiation-assisted hydrothermal degradation of YAG was limited to mild GB etching.

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.