| Issue |

EPJ Nuclear Sci. Technol.

Volume 11, 2025

Euratom Research and Training in 2025: ‘Challenges, achievements and future perspectives’, edited by Roger Garbil, Seif Ben Hadj Hassine, Patrick Blaise, and Christophe Girold

|

|

|---|---|---|

| Article Number | 30 | |

| Number of page(s) | 20 | |

| DOI | https://doi.org/10.1051/epjn/2025026 | |

| Published online | 30 June 2025 | |

https://doi.org/10.1051/epjn/2025026

Regular Article

Exploring the safety and performance of molten salt reactors for their deployment in the European Union: the MIMOSA and ENDURANCE projects

1

Orano 125 Avenue de Paris 92320 Châtillon France

2

Politecnico di Milano Via La Masa 34 20156 Milano Italy

3

Delft University of Technology, Radiation Science and Technology department Mekelweg 15 2629 JB Delft The Netherlands

4

NRG Westerduinweg 3 1755 LE Petten The Netherlands

5

Research Centre Řež 130, Řež 250 68 Husinec Czech Republic

6

Thorizon Amsterdam 1012 SN The Netherlands

7

IJCLab, CNRS/IN2P3, Université Paris-Saclay 91405 Orsay France

8

European Commission, Joint Research Centre Karlsruhe Germany

9

Orano 11 Rue d’Idalie 1050 Ixelles Belgium

10

Nuclear 21 Groenstraat 35 Waasmunster 9250 Belgium

11

Politecnico di Torino Corso Duca degli Abruzzi, 24 10129 Torino Italy

12

LPSC, IN2P3/CNRS, Grenoble INP – UGA, Univ. Grenoble Alpes 53 Avenue des Martyrs 38000 Grenoble France

13

Subatech, IN2P3/CNRS, IMT-Atlantique, Nantes Université 4 Rue Alfred Kastler – La Chantrerie 44000 Nantes France

14

Institut de Radioprotection et de Sûreté Nucléaire (IRSN), PSN-RES/SAG, Cadarache Centre 13108 St. Paul lez Durance Cedex France

15

Framatome 1, Place Jean Millier Courbevoie 92400 France

16

Paul Scherrer Institute (PSI) Forschungsstrasse 111 5232 Villigen Switzerland

17

ARTTIC 39 Rue des Mathurins Paris 75008 France

* e-mail: isabelle.morlaes@orano.group

** e-mail: stefano.lorenzi@polimi.it

Received:

22

November

2024

Received in final form:

12

March

2025

Accepted:

7

May

2025

Published online: 30 June 2025

Molten Salt Reactors (MSR) are Generation IV nuclear systems in which the fuel is dissolved in a molten salt circulating through the primary system. There is growing interest in this advanced technology in Europe, but also in the US, China, South Korea, Japan and Russia, due to their inherently high safety level, flexibility, reliability, load-following capabilities, and potential for multi-recycling of materials contained in light-water reactors’ spent nuclear fuels. These advantages could position MSRs as ideal complements to other decarbonized energy sources in a future sustainable energy mix. In this respect, it is probably one of the most promising advanced technologies and, at the same time, the least mature and studied one. Two ongoing EURATOM-funded projects, MIMOSA and ENDURANCE projects are exploring molten salt reactors’ safety and performance features, as well as fuel cycle aspects, in order to assess and demonstrate their potential for future deployment in Europe. The MIMOSA and ENDURANCE projects have the common objective of improving the maturity of MSR technology. The MIMOSA project develops and analyses multi-recycling strategies for the European Union based on the use of MSR and demonstrates several key aspects of their technical feasibility and performance by both calculations and experimental investigations. The ENDURANCE project supports the safe operation and the development of Critical Technology Elements by connecting design developers and industry with universities and research centres while ensuring alignment with regulatory requirements. Whereas ENDURANCE is in its starting phase, MIMOSA has already delivered important results.

© I. Morlaes et al., Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1. Introduction

Molten Salt Reactors (MSR) are Generation-IV nuclear systems in which the fuel is dissolved in a molten salt circulating through the primary system. There is growing interest in this advanced technology, in Europe but also in the US, China, South Korea, Japan and Russia, due to their inherently high safety level, fuel cycle flexibility, reliability, load-following capabilities, and potential for multi-recycling1 of materials contained in light-water reactors’ spent nuclear fuels. These advantages could position MSRs as ideal complements to other decarbonized energy sources in a future sustainable energy mix. In this respect, it is probably one of the most promising advanced technologies and, at the same time, the least mature and studied one.

The European Union increasingly recognizes the potential contribution of Small Modular Reactors (SMRs) and Advanced Modular Reactors (AMRs)2 to a sustainable and secure energy supply. The Euratom Research and Training Program plays a pivotal role in supporting the development of these technologies, among which the molten salt technology. By funding research projects and fostering collaboration across the European nuclear sector, the Euratom program drives progress in reactor safety, efficiency, and sustainability as well as research related to the fuel cycle. This support is crucial to accelerate the development and the deployment of SMRs and AMRs within the EU, in line with the ambition of the SMR Industrial Alliance [1] of achieving operational SMRs in Europe by the 2030s.

The interest in MSR technology is demonstrated by a long history of R&D projects financed by both EU member states and Euratom. MOST (2002–2005) was the first project funded by EU under the 5th Framework Programme. It sought to evaluate past knowledge on data and develop modelling tools for the study of MSR, with a focus on the graphite-moderated thermal designs operated and proposed in the past as the Molten Salt Reactor Experiment (MSRE) and the Molten Salt Breeder Reactor (MSBR). A review of different liquid salt options for innovative applications was performed in the ALISIA project (2007–2008), where a fuel salt and a design were selected for a European MSR design. The EVOL project (2010–2013) was funded with the aim of improving and evaluating the design of the Molten Salt Fast Reactor (MSFR), a fast-spectrum system based on thorium-fluoride salt option. The design was optimized on the base of neutronics and thermal-hydraulics analysis, focusing also on the blanket arrangement. Different fuel cycles based on U-235 and/or Pu-239 were studied to cope with the lack of U-233 required for the U-Th cycle, leading two options for fuel salt composition. A fuel reprocessing scheme was proposed within the project. The SAMOFAR project [2] (2015–2019) analysed the key safety features of the MSFR. This effort led to the identification and classification of initiating events for MSFR, along with the definition and characterization of fuel properties, the further development of both computational tools, especially for multiphysics analysis, and experimental setups as SWATH-S and DYNASTY. The follow-up project, SAMOSAFER [3] (2020–2023), continued the work on the safety assessment with a focus on severe accidents and safety barriers. The activities performed in the project includes the translation and the adaptation of the current defence-in-depth safety approach to MSR; the development of simulation codes for MSR safe design, safety assessment and severe-accident analysis; and the study of the theoretical and empirical models for the characteristic phenomena and the analysis of thermophysical and thermochemical properties of the fuel salt. Efforts were dedicated to the development of experimental setups and the design of advanced barriers for severe accidents.

Today, two ongoing EURATOM-funded projects are exploring molten salt reactors’ safety and performance features, as well as fuel cycle aspects, in order to assess and demonstrate their potential for future deployment in Europe. The aim of the MIMOSA project [4] is twofold. On one hand, it develops and analyses multi-recycling strategies based on the use of MSR in European countries. Indeed, significant improvement in converting plutonium and minor actinides isotopes into fission products with shorter half-lives can be achieved with the introduction of advanced fast-reactor systems among which the chloride fast MSR is a particularly promising option. In parallel, it demonstrates several key aspects of the technical feasibility and performance of MSR, by both calculations and experimental investigations. The ENDURANCE project [5] aims at supporting the safe operation and the technological development of MSRs in Europe by connecting design developers and industry with universities and research centres while ensuring alignment with regulatory requirements. The project improves the maturity of relevant Critical Technology Elements (CTEs), namely the chemistry of fuel salt and structural materials in the reactor environment; experimental evidence on safety-related phenomena; modelling preparedness for safety assessment and licensing; sustainability and safeguards compliance of MSR fuel cycle; and demonstration of safe MSR adaptability in future decarbonized energy scenario. In this manner, the two projects follow similar approaches with the aim to improve the maturity of MSR. Whereas ENDURANCE is in its starting phase, MIMOSA has already delivered important results, which are described in this paper.

2. Measurement and modelling of fresh and irradiated molten salt properties

The safe and optimal performance of a molten salt reactor design is directly related to the properties of the fuel salt mixture. The thorough characterisation of the salt thermochemical and thermophysical properties is essential to enable the design, safety analysis, and qualification of MSR components, since relevant parameters (e.g., margin to solidification, margin to boiling, mass flowrate, etc.) are dependent on these properties. Furthermore, accurate uncertainty quantification is essential to support the qualification and licensing processes. Therefore, in the ENDURANCE and MIMOSA projects, one of the major aims is to gain knowledge on key fuel salt properties, namely melting temperature, heat capacity, vapour pressure, density, viscosity, and thermal conductivity on different salt compositions. While MIMOSA focuses on the physicochemical properties of two “fresh-fuel” chloride salt compositions, ENDURANCE will be dedicated to the study of fission product systems in both fluoride and chloride salt mixtures.

2.1. Description and results of the measurement campaigns within MIMOSA

In the first year of the MIMOSA project, two specific fuel salt mixtures were selected in the NaCl-MgCl2-PuCl3 and NaCl-ThCl4-PuCl3 salt systems, based on calculations using thermodynamic databases [6–8], coupled with neutronics calculations. Several iterations were necessary to make sure that the final selected mixtures would fit requirements on both thermochemical (notably low melting temperature, high heat capacity, low vapour pressures) and neutronic properties (criticality achieved for the selected reactor configurations).

Synthesis and preparation of the relevant mixtures took place in the second year of the project (Fig. 1). To this end, the synthesis of the two actinide chloride compounds PuCl3 and ThCl4 was first realized from available source materials at the JRC Karlsruhe and TU Delft, respectively. In the case of PuCl3, the experimental apparatus, synthesis technique, and analytical scheme to prove the product purity were already established at JRC Karlsruhe [9, 10] before the start of the MIMOSA project, and were used to prepare the required material to be used during the project. The purity check using a combination of mass balance, phase analysis using X-ray diffraction (XRD), and characterization of melting behaviour via differential scanning calorimetry (DSC) clearly proved that the purity of the PuCl3 product was satisfactory for the high temperature thermodynamic measurements and for corrosion studies. Although no impurity was observed, the purity is estimated to be >99% due to the detection limits of the used techniques.

|

Fig. 1. Synthetized PuCl3 and ThCl4 salts in the lab scale quantities. Characteristic green colour of PuCl3 on the left, and on the right ThCl4 with characteristic white colour. |

The synthesis procedure for ThCl4 was moreover successfully implemented at the TU Delft, leading again to a high purity product (>99%), as confirmed by XRD. Scaling-up of the process is still on-going to produce enough material for all experiments (including corrosion tests – see Sect. 4). In the meantime, CVR purchased NaCl and MgCl2 in several tens of kg. The removal of water was verified by vacuum drying and melting methods.

The melting and transition temperatures of several compositions in the NaCl-MgCl2-PuCl3 system were subsequently measured at JRC and used as input for the re-assessment of the thermodynamic model of this fuel system [7]. In addition, the density of the selected NaCl-MgCl2-PuCl3 composition was also collected for a large range of temperature. The set-up used for the measurement, which is available at JRC, is based on the Archimedean method and has been validated against literature data on inactive salt systems and during the Round Robin tests performed in the recent past [11]. Some key optimizations of the measurement procedure have been implemented, mainly to downscale the amount of sample needed for the measurement to reduce the exposure to radioactive samples and to comply with the glove box installation requirements. Moreover, heat capacity of the same salt mixture was collected using DSC and the step method. The uncertainty of the applied method will be benchmarked to our previous heat capacity measurements on molten salt systems using the drop calorimetry [12–14] to identify the best possible method for future measurements. At the TU Delft, preliminary measurements of the phase equilibria in the NaCl-ThCl4 system were performed using Differential Scanning Calorimetry, complemented by molecular dynamics simulations of thermo-physical properties (e.g., density, heat capacity, mixing enthalpy).

It is also planned within the MIMOSA project to measure vaporization behaviour of the selected NaCl-MgCl2-PuCl3 composition. This will be done using the Knudsen Effusion Mass Spectrometry (KEMS) [15] in a similar manner as done in the past on fluoride and chloride salt systems [16, 17]. Experimental set-ups for the measurement of viscosity, and thermal conductivity at JRC are still under development. Viscosity measurements using a rotational viscometer were successfully performed at room temperature and slightly elevated temperatures (<100°C) using water-based solutions. Optimization of the sample volume and high temperature adaptation are on-going, as required for the measurement of radioactive molten salt samples. Thermal diffusivity will be measured using a Laser Flash technique, from which the thermal conductivity can be derived. This requires optimization of the encapsulation method for molten halide samples. This work is on-going.

2.2. Discussion and perspectives within MIMOSA

Measurements of properties of the two fresh salt mixtures will continue until the end of the MIMOSA project. On the other hand, with a view to the licensing of the MSR technology, it will be essential to perform thermo-physical property measurements on irradiated fuel salts, which is a challenging task due to the high radiotoxicity and the low volume available. The fuel salt properties may be influenced by the numerous fission products that are generated during irradiation, making insights into this aspect highly valuable. As part of the MIMOSA project, we will investigate the technical challenges and explore possible solutions for measuring irradiated chloride salts with the aim of identifying the most suitable techniques and the associated requirements. While MIMOSA does not include irradiation campaigns, these considerations will be highly beneficial once irradiated fuel becomes available.

2.3. Discussion and perspectives within ENDURANCE

To complement activities performed within MIMOSA, the ENDURANCE project will be dedicated to gain insights into the chemistry of irradiated fuel salts, notably the impact of fission products on the thermo-physical properties. First, a round-robin campaign will be organised on the measurement of melting temperatures, heat capacity, density, viscosity, and thermal conductivity on a selected shortlist of salt compositions. The results will be collected in an open repository and will allow for the development of correlations to be implemented and tested in simulation tools. Thanks to uncertainty analyses, best practices for accurate measurements of thermochemical and thermophysical properties, as well as for quality assurance during salt preparation, fabrication, and purification, will be provided towards the qualification process of the involved materials. Given the lack of data [18] and models [19] on density, viscosity, and thermal conductivity of fission product systems, which are representative of irradiated fuel salt, the development of a density and viscosity database coupled to the JRCMSD thermodynamic database is moreover envisaged. In particular, density and viscosity models for unary, binary, and ternary fission products systems will be developed, which will adopt the same mathematical framework as the JRCMSD, i.e., quasi-chemical formalism in the quadruplet approximation. Such coupled thermodynamics-density-viscosity models will be developed for key fission product systems in fluoride and chloride salts, that feature high fission yield, high volatility, and/or high radiological impact. The input for the model development will be provided by experimental data and molecular dynamics simulations. These simulations will rely on the Polarisable Ion Model (PIM) [20], which is well-adapted to such ionic systems. Finally, the models on multi-component systems will be validated by a comparison with experimental measurements and molecular dynamics calculations on simulated irradiated salt of the SALIENT-01 [21] and SALIENT-03 compositions3.

3. Analysis of molten salt composition evolution in the reactor

During irradiation in the reactor, the composition of molten salt evolves and new isotopes appear. These changes are relevant for key aspects of molten salt technology development as sustainability, proliferation resistance, and safety of fuel cycle options and MSR reprocessing schemes.

Within MIMOSA, experiments and advanced computer calculations are developed and employed to simulate the evolution of the chloride molten salt composition inside an MSR, for various evolution scenarios. These experiments and simulations support fuel cycle calculations, safety evaluation, and the analysis of valuable isotopes that can be produced in MSR. Also, considering that accurate nuclear data libraries are essential for all design and licensing calculations, especially as advanced reactor designs increasingly utilize non-traditional structural materials, MIMOSA has focused on developing simple, well-defined experiments to validate nuclear data for chlorine, which is not well characterized as it is not a common material in the nuclear industry, and recent studies [22] show that criticality mispredictions can be significant due to chlorine nuclear data.

On its side, the ENDURANCE project will focus on simulating the detailed nuclide flow inside various MSR concepts and scenarios to investigate the sustainability, proliferation resistance, and safety of fuel cycle options. To support the evaluation of sustainability aspects of the MSRs, nuclide dynamic system analyses of selected MSR concepts will be performed to evaluate nuclide flows throughout the entire fuel cycle. In this context, various sustainability metrics will be analysed and optimised for different scenarios (see Sect. 8.3).

3.1. Description and results of the depletion calculations within MIMOSA

Within the MIMOSA project, four MSR evolution scenarios have been proposed for analysis: they consider two different power reactors’ configurations (10 MWth and 300 MWth) and two different fuel salt compositions for the supply of these reactors (the two compositions defined previously for fuel salt properties measurements – see Sect. 2.1). These four scenarios, including their ‘bis’ variants, are presented in Table 1.

Proposed evolution scenarios with their ‘bis’ variants.

Depletion calculations have been performed with the CNRS REM code [24] for these four MSR evolution scenarios, providing relevant depleted fuel compositions for further analysis of back-end scenarios. As a first step, depletion calculations were performed on reactor configurations proposed by CNRS and Orano, called RAPTOr4.

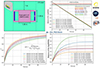

Figure 2 shows the results of these first calculations on different versions of the RAPTOr* concept [25] Interesting results can be identified on these images, such as the fact that converter configurations with a specific power of 250 MWth/m3 mobilise fissile material more quickly than 150 MWth/m3 versions due to the larger number of fissions, but also consume plutonium more quickly and produce less americium, for the same reason.

|

Fig. 2. Results of first depletion calculations performed with the CNRS REM code on reactor configurations proposed by CNRS and Orano (RAPTOr). |

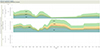

Then, depletion calculations were performed on the four MSR evolution scenarios. Figure 3 shows results for a 300 MWth reactor (2 m3 core) and NaCl-MgCl2-PuCl3 fuel (with enriched chlorine) associated with different actinides provenance: Scenario 2 (supply with Pu ex-MOX, solid line) and Scenario 2bis (supply with Pu ex-MOX and Minor Actinides (MA), dashed line). The preliminary processing scheme developed in collaboration with CNRS was used. These results were used to assess the recoverable materials from this type of concept (see Sect. 5.1).

|

Fig. 3. Depletion calculations for a 300 MWth MSR and NaCl-MgCl2-PuCl3 fuel (with enriched chlorine) associated with different actinides provenance: (Scenario 2: Pu ex-MOX, solid line) and (Scenario 2bis: Pu ex-MOX+ MA, dashed line). |

3.2. Description and results of the salt irradiation experiment within MIMOSA

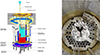

The LR-0 is a zero-power, light-water reactor operating at atmospheric pressure and near room temperature, utilizing VVER-1000-type fuel assemblies with enriched uranium and shortened fission column height to 125 cm. A distinctive feature of this reactor, especially its benchmark core, is the criticality achievement process: the reactor reaches start-up and criticality by continuously pumping the moderator into an initially empty reactor vessel, which is characteristic for shutdown state. Depending on the experimental setup, criticality can be achieved in a partially flooded fuel configuration with control rods fully withdrawn to the top. This approach is beneficial as it eliminates neutron flux depressions caused by absorbing rods, leaving the moderator level as the only critical parameter, which can be precisely measured. Figure 4 provides a schematic and real view of the core.

|

Fig. 4. LR-0 reactor general view (left side), photo of real reactor arrangement (right side). |

Recently, the LR-0 has been recognized as a reference core, which means that it produces well-characterized and repeatable neutron field [26] and therefore it is suitable for validation experiments. The most fundamental cross section validation is checking whether the criticality predictions of this benchmark configuration – with a significant quantity of chlorinated compounds – could be accurately calculated. Only the simplest compounds, such as NaCl, CaCl2, or MgCl2 in solid state at ambient temperature and pressure, have been used in these experiments.

In the described experiments, several kilograms of pure NaCl salt were utilized in the LR-0 reactor, where the NaCl salt served either as an inserted zone within the thermal reactor or as a reflector surrounding the core. The experimental reactor assembly models are shown in Figure 5. Two NaCl column heights – 40 cm and 80 cm – were investigated to assess the effect of the salt's thickness on overall agreement in criticality measurements. A total of 12 independent measurements were conducted across these configurations. The results for both the inserted and salt-reflected core configurations were compared to the reference state with an empty central channel. The results of the critical experiments are presented in Table 2.

|

Fig. 5. LR-0 core with NaCl insertion (left) and core with NaCl reflector (right). NaCl is the grey region. |

Critical levels of the LR-0 with different amounts of NaCl.

These findings indicate that NaCl serves as a poor moderator or reflector within a thermal neutron spectrum. The addition of salt leads to an increase in the critical moderator level compared to the reference state, reflecting its limited moderation capability and predominant absorption properties. This effect is magnified as the quantity of salt within the core increases, resulting in progressively higher critical levels. An exception is observed in the case with a 40 cm salt reflector, where absorption by the salt combines with increased neutron leakage through the void region above it. When compared to the 80 cm salt reflector case, the moderator level is higher, suggesting that the salt's reflection properties are suboptimal; they still offer some improvement over a partly voided configuration.

With experimental critical parameters established, further calculations were conducted using MCNP6.2 [27] with multiple nuclear data libraries: ENDF/B-VII.1, ENDF/ B-VIII.0 [28] JEFF-3.3 [29] and JENDL-5 [30]. Statistical uncertainty in the calculations was maintained below 10 pcm across all cases. Table 3 presents the comparative results in the form of C/E-1, which directly indicates the reactivity deviation from experimental conditions. The results show that, apart from geometrical configuration, reactivity strongly depends on the chosen nuclear data library. While only minor deviations were noted in the reference core, configurations with NaCl insertions revealed notable discrepancies. Notably, while the chlorine data remained unchanged between ENDF/B-VII.1 and ENDF/B-VIII.0, differences arose due to evolved definitions for fuel and structural materials.

Comparison of the calculation vs. experimental agreements in the form of the C/E-1, units are pcm.

To evaluate the impact of chlorine salt definitions, the fuel and structural components in the LR-0 core were fixed to ENDF/B-VIII.0 while the salt insertion and reflection regions were defined using ENDF/B-VII.1, JEFF-3.3, and JENDL-5. Table 3 summarizes the calculation results, revealing that solutions based on ENDF/ B-VII.1 and JEFF-3.3 fall within the calculation's statistical uncertainty, whereas JENDL-5 demonstrates markedly improved performance.

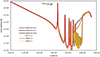

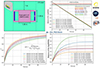

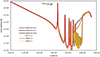

This improvement likely arises from differences in chlorine cross-section evaluations: while ENDF/B-VII.1, ENDF/B-VIII.0, and JEFF-3.3 share the same chlorine data, JENDL-5 includes a distinct chlorine definition. In thermal-spectrum reactors, scattering and absorption cross sections significantly influence results. Although the total cross-section differences may be minimal, probabilities for specific reactions – such as 35Cl(n,p), shown in Figure 6 – can vary. Larger discrepancies are expected in fast-spectrum systems, for which dedicated validation experiments are currently under development.

|

Fig. 6. Comparison of the different evaluations of 35Cl(n,p) reaction. |

Based on the preliminary experiments, the conclusion can be drawn that the current and even the most recent nuclear data evaluations have significant reserves and exceeding uncertainties for systems containing large concentrations of chlorine. The improvement of the chlorine evaluations are essential for correct prediction of criticality, which is necessary for design as well as accidental scenario studies. This necessity might be amplified for the systems working with fast neutron spectrum. Experiments with other chloride salt components as CaCl2 or MgCl2 are under evaluation. Further research should also aim at the validation of the prompt gamma production to correctly predict doses from gamma, which influence not only structures by damaging or heating, but also personnel doing the regular maintenance.

3.3. Discussion and perspectives within MIMOSA

In most molten salt reactor designs, the liquid fuel is not static. Movement of salt fuel in and out of the critical volume affects the salt fuel composition (by introducing periods of fission product decay), reactivity control (through the movement of fission products), and dose rates and heat production away from the reactor core. For this reason, analysis of molten salt reactor physics in principle requires strong coupling with thermal hydraulics.

A simple MSR loop-system will be applied in MIMOSA to perform code verification and numerical parameter studies with MSR codes. The ultimate goal of this numerical task within MIMOSA is to (1) assess delayed neutron effects in a simple loop system, and (2) compare different simulation approaches. The calculations will start simple, with fixed core power, flow rate and salt properties in order to calibrate the MSR codes. Gradually, the calculations will be made more complex (and realistic), to identify potential code differences and deficiencies.

3.4. Description of the depletion calculations within ENDURANCE

On its side, the ENDURANCE project will focus on two types of irradiation calculation. On the one hand, many MSR concepts will be evaluated in a simplified manner on lattice level, considering a basic unit of fuel salt, structural materials, and moderator blanket, if any. These simulations should enable intercomparison of neutronics and fuel cycle performance between the concepts. At this stage no detailed reprocessing scheme will be included. Part of the activity is a definition of fuel cycle performance criteria and evaluation of the fuel cycle sustainability from natural resources utilization perspective. On the other hand, the simulations of detailed nuclide flow inside the system of various MSR concepts for several scenarios will be investigated. These simulations should confirm the earlier identified capability to utilize natural resources. At the same time, the full core simulations with detailed nuclides flow will enable evaluation of proliferation resistance, waste streams, and safety related coefficients. The waste stream will be extended to the immobilisation step and discrete storage casks should be ultimately evaluated from radiotoxicity and decay heat perspective. The SAMOSAFER benchmark for depletion tools will be further extended by its in-depth evaluation and addition of chloride salt cases. Ultimately, it should provide a handy option for the code developers, to verify the tool after some changes. It should also provide a simple option to identify errors in the input file for given simulation. For one or two selected concepts a scenario study is foreseen, where the MSR will acts as one of many reactors in the same fuel cycle scenario. It includes dynamic system analyses with transitions between fuel cycle types. The nuclide flows and waste streams will be evaluated throughout the entire scenario. In this context, various sustainability metrics will be analysed and optimised for different scenarios.

4. Analysis of corrosion and mechanical behaviour of structural materials in interaction with molten salt

Corrosion is considered as one of the major technical challenges of molten salt reactors. A thorough assessment of corrosion mechanisms under mechanical stress and irradiation is fundamental to favour the design, safety analysis, and qualification of MSR components.

Within MIMOSA, a full experimental program has been proposed [31] to study corrosion on several samples of metallic and ceramic materials, in association with the two fuel salt compositions defined for the project. Specific equipment is also being designed and built to study corrosion in static and dynamic conditions. In addition, a molten salt proton irradiation facility was designed during the project [32] and is now commissioned and in service. Besides, a separate neutron irradiation facility has been designed for use at the HFR in Petten, to study the speciation of fission products and irradiated salt and investigate the interaction with salt-bearing materials. In parallel, corrosion monitoring and mitigation techniques have been developed and analysed.

On its side, the ENDURANCE project seeks to characterize the interaction between salt corrosion mechanisms, irradiation, and mechanical stress of structural materials.

4.1. Description and results of the corrosion tests performed within MIMOSA

A test matrix for corrosion studies has been completed, with four phases of increasing complexity and duration. The simplest stage – the so-called ‘phase 0’ – is a high throughput exploration of the sample space. It consists of a partial exposure: a salt droplet fused on top of a material coupon, based on the methodology described by Wang et al. [33]. It is also a shorter exposure (120 h) than the ensuing, more complex phases. At the time of this writing, all the selected metallic materials have been covered. A critical analysis of the results will inform a narrower selection of these materials to take further to the next battery of tests (phases 1 to 3).

Meanwhile, Schunk Carbon Technology has manufactured a variety of silicon carbide samples, paying special attention to the porosity of the finished material. Porosity and free silicon content are two important parameters which may affect the corrosion resistance of these kinds of materials in molten salt environments. The samples have been delivered to TU Delft to be included in phase 0 tests. At NRG, larger specimens have also undergone mechanical testing. The mechanical properties before and after salt immersion will then be compared to assess the effect of chemical interactions between molten salt and material on their structural performance.

At JRC-Karlsruhe, full immersion static corrosion tests have been executed (phase 1) with surrogate salts. A new crucible designed at the institute allows the immersion of small coupons, in the order of a few mm2, in hundreds of mg of salt. The design enables immersion tests with actinide-bearing salts which are difficult to manufacture and handle in large amounts due to the specialized infrastructure required, while still providing standard-compliant results. Figure 7 shows a stainless-steel coupon before and after exposure to molten chloride salt.

|

Fig. 7. Small coupon immersion at JRC Karlsruhe. Before exposure (left) and after exposure (right) to a chloride salt bath for 500 hours. |

Finally, two irradiation setups have been designed during the project although they will not be used within it. One is the in-pile irradiation facility designed by JRC-Petten and NRG, specifically for use at the HFR, and the second is the DIFFER Irradiation Corrosion Experiment (DICE).

NRG has performed a pre-feasibility study on a molten salt irradiation test facility to irradiate representative, actinide-bearing salts on the order of a few ml, building on the SALIENT molten salt test facilities irradiated in the past [21, 34]. These irradiation facilities are cylindrical, with multiple cylindrical containments, equipped with thermocouples, to be placed in a low-medium neutron flux irradiation position in the core of the HFR in Petten. The main fissile actinide used in these tests is LWR-plutonium, although its content needs to be limited in order to keep power production within the capsules at a manageable level. The preparation of the salt irradiation (synthesis of salt, manufacturing of capsules…), the irradiation itself, and the post-irradiation examinations, however, it is not a part of MIMOSA due to budget constraints.

In parallel, the Dutch Institute for Fundamental Energy Research (DIFFER) has designed the DICE facility, which is a molten salt chamber connected to a proton accelerator. In this facility, a thin sheet of material is exposed to high energy protons on one side, and molten salt on the other. Since the material is thin, the proton energy is deposited in the region which is in contact with the molten salt, such that the sample is simultaneously corroded and irradiated (Fig. 8) While other research instruments are able to produce simultaneous corrosion-irradiation environments, the DICE facility is unique in the large damage rate it is able to impose (e.g., 0.9 dpa/24 h at a depth of 25 microns using a current of 30 μA on a 1 cm2 spot), surpassing the prior state of the art by an order of magnitude [35]. With such a damage rate, it is possible to achieve dpa levels representative of in-core damage in a few days, which makes DICE a very useful characterization platform for nuclear materials in service environments. As for the molten salt irradiation test in the core of the HFR in Petten, construction and tests in DICE do not take place in the MIMOSA framework due to budget constraints. However, the device has been built, and first tests have been done outside the MIMOSA project.

|

Fig. 8. Schematic illustration of DIFFER's DICE facility. The proton beam collides with the sample on the left and produces radiation damage up to the metal/salt interface on the right. |

4.2. Description and results of the corrosion mitigation analysis within MIMOSA

To gain a better understanding of the corrosion chemistry, MIMOSA investigates the effects of corrosion products on the salt properties and develops corrosion control methods for molten salts in MSRs.

A literature review of corrosion chemistry in chloride salts was performed and identified chromium and iron as two key elements susceptible to dissolve into the salt, thereby affecting the salt properties. Detailed experimental studies of the NaCl-CrCl2, NaCl-FeCl2, NdCl3-CrCl2 and NdCl3-FeCl2 systems were initiated, combining synthesis of relevant stable phases, and phase diagram equilibria investigations by Differential Scanning Calorimetry and X-ray diffraction. Thermodynamic modelling of the NaCl-CrCl2 and NaCl-CrCl3, FeCl2-CrCl2 systems was performed, leading to one publication [36]. Higher order corrosion systems involving the aforementioned binaries are under study as well.

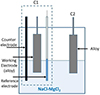

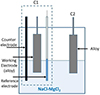

CNRS has started corrosion experiments in order to study several ways for corrosion mitigation in molten salt environment. Bibliographic study has evidenced the strong correlation between the redox potential of the molten salt and the corrosion rate of metallic alloys. Therefore, the objective of the work done in CNRS is to propose several ways to control the redox potential in the salt in a domain where the corrosion of materials does not occur. The first study has consisted in realising immersion of samples in NaCl-MgCl2 at 550°C without any control of the redox potential to have a corrosion reference point. The experimental device is presented in Figure 9.

|

Fig. 9. Experimental device used for corrosion studies. |

On Figure 9, the part C1 leads to record the open circuit potential (OCP) of the sample during the immersion duration. C2 correspond to the sample immersed. No measurement occurs on C2. The first results obtained are presented in Figure 10. We observe on the alloy surface (C2) a corrosion on the surface of the alloy characterized by the formation of a layer which is not adherent: big parts of the surface are not covered by the oxide layer. The average weight loss measured for seven days of immersion is 0.3 mg/cm2.

|

Fig. 10. Photos of the surface of C276 after 7 days of immersion in NaCl-MgCl2 at 550°C. |

4.3. Discussion and perspectives within MIMOSA

The next stage of corrosion tests will be phase 2, comprising static immersion tests of samples which can then undergo mechanical testing. Building on the knowledge gained from the previous stages, phase 3 will focus on dynamic corrosion testing, and will involve the use of a small thermal-gradient-driven loop as well as a novel electrochemical cell to be constructed at the TU Delft. Next immersion studies will be done in NaCl-MgCl2 mixture with a control of the redox potential of the salt and the samples after immersion will be compared with the samples immersed in the salt without control of the redox potential.

4.4. Discussion and perspectives within ENDURANCE

To evaluate the combined effects of mechanical stress and irradiation with salt corrosion, different sets of experiments will be performed in the context of the ENDURANCE project. First, sequential corrosion and mechanical experiments will be carried out, involving static tests where specimens with specific geometries will be exposed to fluoride salts. The samples will be also characterised with mechanical tests, such as tensile tests, miniaturised tensile tests, and small punch tests. Corrosion-creep experiments in fluoride salt melts at high temperatures will combine simultaneous corrosion and mechanical load at high temperature, where mechanical stress will be applied by an experimental device. Finally, post-irradiation examination (PIE) of the SALIENT-03 irradiation campaign, consisting of 5 sealed Hastelloy N capsules containing LiF-ThF4-UFx-PuF3 salts with some compositional variation, will be performed. In particular, 2D gamma emission spectroscopy and puncturing to obtain fission gas release fractions will be done on the capsules to analyse fission product volatilization and deposition under MSR representative conditions. Quantitative gamma analysis and calibrated burn-up analysis will be carried out. Thanks to microscopy, Cr and Fe distributions in Hastelloy N will be estimated, giving insight into the effect of irradiation on the extent of the corrosion.

5. Analysis of spent fuel salts management options

The reprocessing of Spent Nuclear Fuel (SNF) and the selective separation of fission products and actinides form the cornerstone of any nuclear material recycling strategy and the implementation of advanced nuclear systems, such as the MSR, requires the development of new technologies associated with the back end of the fuel cycle and/or the adaptation of existing technologies. Within MIMOSA, we develop methods for treatment and recycling of spent fuel salts, with a primary emphasis on enhancing sustainability and efficiency of waste management. The primary goals include studying the integration of spent fuel salt treatment within the La Hague hydro-metallurgical reprocessing scheme, exploring alternatives such as pyrochemical treatments and direct glass conversion, and analysing these treatment options to recommend the optimal route (Fig. 11). Within ENDURANCE, different salt clean-up techniques and reprocessing schemes will be evaluated.

|

Fig. 11. Main recycling scenarios considered within MIMOSA. Some key technological solutions (depicted in yellow) are under study to assess and compare the fuel treatment options identified. |

5.1. Description and results of the study of treatment and recycling salt in La Hague within MIMOSA

This study focuses on assessing the compatibility of chloride-based nuclear fuel with the La Hague reprocessing facility. Orano is conducting an in-depth technical study to determine the requirements to integrate chloride fuel into La Hague's existing reprocessing streams. Key challenges addressed in the study include minimizing chlorine inventory to prevent equipment corrosion, and understanding the impact of unconventional concentrations of actinides, fission products and primary fuel constituents (e.g., Na, Mg) on the facility's process, waste generation, regulatory compliance and criticality aspects. In collaboration with CNRS, the work has also involved defining eight reference scenarios (Fig. 12), each representing different strategic choices and assumptions about fuel salt compositions and reactor designs. These scenarios include variations such as Mg-based salts vs Th-based salts, First-of-a-Kind (FOAK) reactors vs reactor fleets and a range of projected technological maturity levels, all aligned with the previous configurations and scenarios described in chapters 2, 3 and 4.

|

Fig. 12. Reference scenarios considered for salt treatment. |

For each scenario, the evolution of fuel composition over time has been calculated to provide input compositions essential for evaluating treatment options. In this framework, spent fuel in chloride form undergoes complete conversion through a pre-dissolution step, transforming it into a chemical form compatible with the current streams at the La Hague facility. Simultaneously, the JRC is conducting a complementary study focused on optimizing the dissolution and recovery of chlorides in nitric acid. A representative salt sample, incorporating select fission and corrosion products that may pose challenges during dissolution, is being prepared for testing. This experimental approach will allow, within MIMOSA, to identify and address specific dissolution challenges related to chlorides and other potential impurities, contributing valuable insights to the overall chloride fuel treatment strategy. The technical study's findings will ultimately yield critical compatibility guidelines, including optimal dilution parameters, that will inform the necessary adaptations for chloride fuel integration within La Hague's operations, in case this option would be implemented in the future.

5.2. Description and results of the study of treatment and recycling salt with a pyrochemical process within MIMOSA

In parallel, CNRS is investigating pyrochemical processes to remove neutron poisons (primarily rare earth elements) and minor actinides from spent fuel salt. In doing so and depending on the separation efficiency achieved, only a small amount of the salt – compared to the total amount treated in a purely hydrometallurgical process – will need to be processed and conditioned as waste. These methods, which have lower TRL, offer potential advantages, simplifying the overall scheme while reducing the amount of salt produced, transported and treated.

Current research progress includes a comprehensive review of the different pyrochemical strategies and the selection of the most suitable extraction methods using liquid metals or solid electrodes. Experimental results have identified the most effective liquid metals for extraction with promising outcomes for the reductive extraction of lanthanides and actinides. By optimizing surface contact between the alloy and the salt, a complete extraction of cerium has been achieved in less than an hour (Fig. 13). Similar experiments will be now carried out on other elements to verify the extraction efficiency obtained. Finally, fundamental data on the electrochemical behaviour and chemical stability of target elements are being gathered to develop a selective extraction approach for lanthanides and minor actinides.

|

Fig. 13. Experimental assembly used for the reductive extraction experiments of cerium on a metallic alloy. |

5.3. Description and results of the study of salt vitrification within MIMOSA

As part of a multi-recycling scheme for plutonium waste, chloride waste containing fission products will have to be conditioned for final storage. A promising alternative to the current solution, particularly compatible with pyrochemical processes, involves stripping halides directly from the cations using an appropriate halide gas former. NRG is focused on this task, aiming to convert chloride waste into either borosilicate or phosphate glass. Initial experiments have been conducted on representative chloride salt compositions, incorporating key fission products in a laboratory setting (Fig. 14). The goal is to establish a robust vitrification method, with ongoing experiments aimed at refining this process. Future tests will target actual chloride waste to ensure that the vitrified waste meets all necessary standards for safe storage and disposal.

|

Fig. 14. A vitrified sample of surrogate materials as LiCl-ZrCl4 in borosilicate glass. |

5.4. Discussion and perspectives within MIMOSA

When results from studies on La Hague processing and pyro-processing will be available, MIMOSA project will compare the various salt treatment methods studied to recommend the most efficient and effective route. This analysis will synthesize the findings from the previous tasks to provide a comprehensive strategy for treating spent fuel salt, ensuring optimal safety, efficiency, and environmental protection.

These efforts are crucial in advancing sustainable and safe methods for treating spent fuel salt, contributing to the broader goals of efficient nuclear waste management and environmental protection.

5.5. Discussion and perspectives within ENDURANCE

The evaluation of nuclide flow, which is critical for assessing the source term, radioactive inventory, and investigating the MSR proliferation resistance, is strictly related to removal rates and efficiencies for the reprocessing schemes. Therefore, different salt clean-up techniques, which remove fission products without a strong change in salt composition, and reprocessing techniques, which affect deeply the salt composition, will be explored within ENDURANCE. In particular, the efficiency, pace, and reprocessed batch size for different salt clean-up and reprocessing schemes will be analysed to give insights on their impact on fuel performance, on safety, and on proliferation resistance. The initial simulations will be based on the reprocessing techniques and efficiencies described in SAMOSAFER deliverables. At the same time, it is foreseen to accomplish a literature review combined with an expert assessment of each individual reprocessing technique. Based on the collected data, impact of each partial repro processing step on waste amount, fuel cycle sustainability, and proliferation risk will be evaluated.

Another ENDURANCE project task is to propose and investigate a passive salt clean-up technique as an alternative to the off-gas system based on active He sparging. This passive off-gas system relies on negative pressure difference, which provides safety and economic benefits by simplifying and reducing gas pressure in a system that carries radiotoxicity. In particular, the fuel salt should be partly redirected from the primary circuit to a salt shower passing through a low-pressure chamber. The high surface of the droplets will accelerate the gaseous fission products release, and the splashing of the droplets on the walls may result in metallic particle deposition. Thanks to the tools developed in the context of the SAMOSAFER project [37, 38], the radionuclide releases from fuel salt during nominal conditions and at elevated salt temperatures will be simulated, allowing for a comparison with the performance of standard off-gas systems.

6. Value assessment of radionuclides produced in a MSR and analysis of recovery techniques

Due to its particularity of using a liquid fuel, the MSR offers the possibility of recovering certain radionuclides just after their production in the core and, therefore, before their decay. This is the case for gaseous fission products and solid particles. The gaseous elements are naturally removed from the salt immediately after their production. The solid particles such as metallic elements can be removed with the gas through a flotation process, previously observed in the case of MSRE at ORNL.

Within MIMOSA, we evaluate the possibility of recovering some valuable isotopes produced in MSR. We have established the list of elements that could be valued. Tests are performed to explore on one hand the possibility of separating the platinoids by chlorination, and on the other hand of extracting both fission gas and solid particles with a bubbling device designed for that purpose.

6.1. Market assessment of valuable isotopes within MIMOSA

A global view of all the valuable radioisotopes and materials that could be extracted from a Molten Salt Reactor has been established. Among them, we can cite: PGM (Platinum Group Metals) elements which are used in many applications (chemistry, CO2 conversion or hydrogen production), Xe-133 and Mo-99 for medical applications and Kr-85 for measurement and electronics application, e.g., in the growing electric cars battery production market (thickness measurement). PGM elements and Mo are fission products which are theoretically formed in the core as metallic particles. Xe and Kr are gaseous elements.

Several criteria have been considered to evaluate the interest to develop an extraction for these isotopes: production capacity, financial impact, market, technical complexity to recover the elements. It was shown that 3 elements could have a high financial impact. This is the case of Rh (all isotopes), Sr-90 and Kr-85. The extraction of these elements could be considered for future research.

6.2. Description and results of the study of recovering valuable isotopes within MIMOSA

As part of the MIMOSA project, the metallic state of the fission products formed in the core fuel salt, specifically Pd, Ru and Mo (elements of PGM group) is being verified experimentally. A thermodynamic database of the main elements of the PGM group is also established to explore the possibility of separating these platinoid elements by chlorination. In this context, the thermodynamic database of Mo and Nb have been already determined. Next studies will be focused on Rh which was identified as element with a high financial impact.

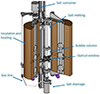

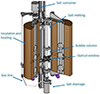

Obviously, the gaseous fission products formed in the fuel salt, because of their low solubility in the molten salt, will be naturally removed from the fuel salt and managed in a special gas unit next to the reactor. As it was evidenced by the Oak Ridge National Laboratory during the Molten Salt Reactor Experiment (MSRE based on a fluoride salt) operation, the gas bubbles formed in the reactor carry through a flotation phenomenon the solid particles formed in the reactor. It is this particularity that we wish to exploit to recover gases and solids of interest at the same time and at the same place. In the frame of MIMOSA project, one objective is to experimentally verify the flotation process in a chloride molten salt. During the first period of the project, a device in aqueous solution was developed. Based on this first experimental feedback, a new device able to study the flotation in a molten salt is under construction in Delft (Fig. 15). Several parameters will be studied at the rate of gas flow in the column and the size of the solid particles on the extraction efficiency. Results will be available by the end of the project.

|

Fig. 15. Design of the molten salt bubble column with viewing ports, insulation, loading and drainage. |

6.3. Discussion and perspectives within MIMOSA

MIMOSA will attempt to verify the proportion of metal particles recovered by gas bubbling. MIMOSA will also attempt to verify experimentally the proportion of metallic particles recovered by gas bubbling. The device with molten salt is currently being developed in TU Delft, and the first results are expected mid-2025.

7. Modelling and experimental activities to enable safety assessment and licensing

Given the requirement to satisfy safety functions with a high degree of reliability, the ENDURANCE project will perform experimental activities to characterise phenomena inherent to the MSR technology and relevant for safety-related components. Furthermore, considering the licensing process of the MSR technology, molten salt designs are required to match the European regulatory environment, which includes recognised and shared practices and high-level standards. Within this process, the safety assessment imposes the identification and quantification of uncertainties deriving from a lack of extensive practical experience and modelling assumptions.

Concerning the experimental campaigns on phenomena relevant for safety, the experiment specifications will be guided by an accurate PIRT analysis and supported by existing advanced simulation tools. In a second stage, a comparison between numerical models implementing experimental conditions and the experimental results will be carried out. Also, specification requirements for large experimental facilities to qualify materials and components will be defined.

First, a new experimental facility will be devoted to obtaining data on the interactions between the solid fission products and the noble gas bubbles, on their transport in a molten salt two-phase flow (i.e., fuel salt and gas bubbles), and on the deposition of metallic particles on the surface walls of the circuit. These phenomena are relevant for safety due to build-up on structural walls and possible clogging of heat exchangers channels, resulting in localised heat loads and radioactive sources. The experimental dataset will then be used to extend and validate numerical models for the transport of the solid fission products, deposition on the structural components, and interaction with the bubbling system for the removal of gaseous fission products. Additionally, two experimental campaigns will generate new nuclear data representative of the influence of structural materials and salts on neutronics parameters. The first experiment will exploit the LR-0 research reactor to perform static measurements on different structural materials and fluoride salts to assess their impact on reactivity worth and neutron spectrum [39]. The second experiment is meant to study radiation shielding and neutron slowdown and will be carried out in the LVR-15 reactor. The neutron beam of this reactor will allow to characterise the neutron transport and penetration in the selected structural material thanks to flux attenuation and neutron spectrum measurements [40]. Two sets of experiments will be developed to collect data on the stability of natural circulation considering internal heat generation in complex cavities and 3D configurations. First, a new experimental setup will allow for the measurement of the flow time fluctuations and flow spatial distribution in complex 2D or pseudo 3D geometries. Then, the DYNASTY discharge tank [41] will be employed to characterize the three-dimensional effects related to recirculation regions and local turbulence in natural circulation regime within a cylindrical cavity with external (heating stripes) or internal (hot wire) heat generation.

As previously mentioned, in light of the licensing process of the MSR technology, the uncertainties deriving from a lack of extensive practical experience and modelling assumptions should be quantified and assigned to risk assessment metrics, setting specific modelling tool requirements for safety-related processes. In terms of MSRs, the characteristics inherent in a circulating fuel salt justified extensive research efforts to develop multiphysics tools [42] to describe phenomena such as delayed neutron precursor drift, strong coupling between neutronics and fluid dynamics, internal heat generation, transport and deposition of fission products, and salt chemistry. Nonetheless, these simulations suffer from a lack of a proper description of the heat exchangers, the intermediate circuit, and the energy conversion system and may hinder the inclusion of the uncertainty quantification process. Therefore, the ENDURANCE project aims to develop computational chains able to combine well-elaborated systems codes and high-fidelity tools to allow a proper evaluation of the uncertainties and demonstrate the modelling preparedness for safety assessment and licensing.

First, safety-related phenomena relevant to analysing compliance of different MSR concepts with current regulatory requirements will be identified and ranked according to a PIRT. These processes should be simulated adopting either multiphysics or system code modelling and considered in the safety assessment process for MSR systems. The outcomes of the PIRT will serve to establish Target Accuracy Requirements (TARs) for the tools that define acceptance limits or compliance criteria required by the safety assessment. Given the needs and requirements for modelling and simulation highlighted by the PIRT and the TARs, two coupling approaches between multiphysics codes and system-level tools will be developed, i.e., domain overlap (CFX and TRACE [43]) and Functional Mockup Interface (PoliMi with OpenFOAM and Modelica [44]). Following the Hi2Lo methodology, reduced order models, meta-models, and correlations will be derived and included in Best Estimate codes with internal assessment of uncertainty, i.e., TRACE, ATHLET, and CATHARE. The ultimate goal is to provide informed system-level tools with high-fidelity capability. The feasibility of non-intrusive, general-purpose uncertainty and sensitivity analysis methods to be applied to the computational chains will then be investigated.

Finally, these computational chains will be verified and tested on respectively experimental and purposefully developed problem-oriented numerical benchmarks. The objective of this latter is to evaluate the preparedness of the modelling tools with respect to compliance with the safety assessment requirements and demonstrate the possibility to compensate for the lack of practical experience. Furthermore, the feasibility of the BEPU (Best Estimate Plus Uncertainty) approach for MSR systems will be addressed along with a comprehensive analysis of the modelling uncertainties and discrepancies. Thanks to these activities, recommendations on the evaluation and design of problem-oriented experiments and safety assessment requirements will be established.

8. Integration of MSRs in decarbonised energy scenarios and multi-recycling scenarios in Europe

MIMOSA and ENDURANCE both investigate the potential of MSRs in terms of integration in decarbonised energy systems, with a particular focus within MIMOSA on the role of MSRs in multi-recycling scenarios in the EU. Within ENDURANCE, insights on safeguards, security, and sustainability topics will be provided, as well as the assessment of the safety aspects of the MSR flexibility in terms of operation and poly-generation requirements.

These studies are nourished by all the experiments and calculations performed in the MIMOSA and ENDURANCE projects, that allow to assess Critical Technology Elements of molten salt technologies, to finally give a global and holistic view on MSR characteristics and capabilities in the hypothesis of a future deployment in Europe.

8.1. Description and results of the scenarios study within MIMOSA

Within MIMOSA, we analyse strategies for multi-recycling of SNF from LWR in European countries, with a special focus on the role that MSRs could play in such advanced nuclear energy systems. These strategies take full account of past and present SNF and Pu/REPU (reprocessed Uranium) management in Europe, with future scenarios based on the most reasonable deployment of nuclear infrastructure, i.e., nuclear power plants and fuel cycle infrastructures, as well as Deep Geological Facilities (DGF). MSR are assumed to achieve the long-term sustainability, both by providing the non-electric energy generation function and the multi-recycling function, reducing the amount and longevity of high-level waste to be disposed of.

The assessment of the MSR in EU addresses two essential dimensions, i.e., the energy market dimension in which MSRs can bring co-generation solution to a variety of end-users, on the intra-nuclear dimension in which MSRs perform the multi-recycling function of nuclear materials from different spent fuel origins.

A two-track approach (see Fig. 16) is used to project the deployment scenarios for MSRs throughout the EU along these two dimensions. A first round of scenario analysis projects the addressable nuclear energy demand in the EU and the possible deployment of MSRs serving this energy demand. It also estimates the future LWR SNF-arising's throughout the EU and assesses the possible deployment of MSRs for the multi-recycling of these SNF with the prime perspective to relieve the SNF-inventory in various EU countries. The second round of scenario analysis then confronts the two dimensions to seek the synergies between them and present more realistic, albeit illustrative, MSR-deployment scenarios in the EU.

|

Fig. 16. Two-track approach to assess the energy and the intra-nuclear function of MSRs. |

MIMOSA has already provided a comprehensive view on the future prospects for nuclear energy in Europe and the projected inventories of SNF and fuel cycle service needs for the decades to come. It is largely based on ‘evolutionary’ scenarios with LWR-technology and gradually some LWR-technology SMRs and Fast Reactors though not yet introducing molten salt reactors (MSRs) as such. The outcome of this analysis is the projected SNF amounts, separated nuclear materials and waste arising, includes the isotopic compositions for all these materials, for the decades to come.

The projected trans-uranics (TRU) quantities and isotopic compositions that would be separated and destined for vitrification, if not sent to MSRs, has been analysed. Figure 17 shows, the scenario in France where the TRU-flows are among the first in the foreseeable future, such main annual TRU-flow from reprocessing with the key isotopes to be managed over time, and thus possibly destined for management in MSRs. The differences in fuel cycle options clearly impact the requirements for MSRs.

|

Fig. 17. Projected possible TRU-flow from reprocessing SNF from the French nuclear reactor fleet. |

In parallel, a Reduced Order Model (ROM) of MSR has been developed, to represent the in-core burn-up evolutions for a variety of input compositions coming from recycling scenarios. Specifically, the possibility to model batch-fuelled as well as continuous fuelling operational modes of MSRs have been finalised in view of performing an updated round of scenarios analysis. The work is driven by a desire to replace regular burnup analysis where a large set of ordinary differential equations for the nuclide densities are solved, by an almost equivalent, but smaller set that is less computationally intense. The ROM model has been verified and is now integrated within the DANESS scenario analysis code by Nuclear-21.

8.2. Discussion and perspectives within MIMOSA

Future work on the ROM model will focus on inclusion of more sophisticated functions, e.g., online chemical reprocessing and bubbling. Further, more practical salt initial compositions will be considered to produce snapshots. Finally, means to include the shape of the neutron spectrum will be investigated.

The second round of scenarios, which has already started, will combine the two tracks and present more integrated energy/intra-nuclear scenarios for MSRs. This second round of scenarios will also integrate a more detailed assessment of the security and safeguards considerations for such advanced fuel cycles next to economic evaluations of such scenarios.

All the results and supporting analyses will be gathered and shared with all kinds of stakeholders such as EC and national energy policy makers, citizens, MSR research and innovation community and designers, end-users (utilities, industries, …).

8.3. Discussion and perspectives within ENDURANCE

The ENDURANCE project will pursue a huge effort in the evaluation of sustainability, proliferation resistance, and safeguardability of MSRs that are strictly related to the flexibility in the fuel cycle and reprocessing schemes of this reactor concept. First, a standardised approach will be developed to evaluate the fuel cycle sustainability performance in terms of resource utilisation, waste production, long-term radiotoxicity, proliferation resistance, and possible radiotoxicity release during an accident. Indeed, different tools will be exploited in the performance evaluation, implemented either in infinite lattice or full core levels. These analyses will support the optimisation process based on sustainable indicators such as waste volume, radiotoxicity, fissile inventory, and mining activity. Proliferation resistance and safeguardability of different fuel cycle options and reprocessing schemes will be also evaluated. Starting from the waste treatment, parameters for cask size and waste will be characterised considering MSR-glass matrixes. The gamma spectroscopy on fuel related waste will be analysed for the MSR fuel streams in order to provide practical guidelines. Moreover, general and high-level considerations on proliferation resistance and safeguardability of the MSR technology will be highlighted, focusing on the design technical features, and nuclear material characteristics.

The integration of MSRs in decarbonised energy scenarios calls for the assessment of the safety aspects of the MSR flexibility in terms of operation and poly-generation requirements. The interest stems from the growing penetration of variable renewable energy sources, which necessitates a transition from the traditional use of continuous baseload power and the high temperatures of the MSR nuclear process, which enhance the efficiency of non-electrical applications. Within ENDURANCE, a trade study approach will highlight a first vision of the operational strategy for electrical and non-electrical end-uses and the potential limitations and opportunities for flexible use of MSRs. Subsequently, different poly-generation options will be identified and analysed, focussing on hydrogen production systems, thermal storages, and industrial heat applications. The selection of poly-generation configurations and the evaluation of the design constraints on structures, systems, and components will guide the assessment of preliminary plant architectures. The evaluation of the MSR operational flexibility will be supported by the use of numerical simulation tools to analyse the operational transients induced by non-electrical applications. The dynamics analyses will focus on the whole plant arrangement, composed by the nuclear part and the poly-generation systems in the various configurations selected. Both multiphysics codes and system codes modelling approaches will be considered exploiting a TFM-OpenFOAM coupled code [45] and Modelica [46], respectively. Furthermore, an integrated framework for the Real-Time Optimization of the system operation policies of the poly-generation production strategies will be developed. Concerning the identification of safety concerns related to the flexible use and poly-generation configurations, a functional safety analysis will be performed. Thanks to the activity previously described, a shortlist of potential safety issues will be outlined, as well as possible initiator events and complementary requirements and recommendations for MSR designs.

9. Conclusions

To achieve Europe's goals of energy resilience, independence and competitiveness, a fast transition to a more sustainable energy system is essential. Nuclear energy has proven to be a safe, reliable and decarbonized energy source. Renewed projections, particularly in light of geopolitical situations and the EU target of energy independence and security, have shown a growing prospect for the inclusion of the nuclear energy in the energy mix. The use of nuclear energy goes with the generation of spent nuclear fuel, presenting socio-political concerns, particularly due to delayed deployment of final management solutions, together with the very long-term stewardship required for such spent fuels. In this context, MSR appears as one of the most promising technologies for the future energy systems of European countries due to their inherently high safety level, fuel cycle flexibility, reliability, load-following capabilities, and potential for multi-recycling of materials contained in LWR spent nuclear fuels.

The aim of the two ongoing EURATOM-funded projects, MIMOSA and ENDURANCE, is to explore MSRs’ safety and performance features, as well as fuel cycle aspects, to assess and demonstrate their potential for future deployment in Europe. Both projects share a systematic approach to improve the maturity of both reactor and fuel salt aspects. In this respect, they show many similarities, namely the methodical assessment of the most critical technology elements and the parallel use and benchmark of experimental results and simulations. While they address complementary fields of knowledge that will finally map a broad spectrum of technical topics linked to MSR, (1) MIMOSA focuses on chloride salts and fast spectrum MSR only, with the goal of assessing their multi-recycling capabilities within realistic deployment scenarios in European countries, while ENDURANCE addresses both types of salt (fluoride and chloride), with a focus on safety-related phenomena assessment and licensing approach, safeguarding and flexibility capabilities; (2) MIMOSA has chosen specific families of salts and hypothetic MSR designs to develop various fuel-related scenarios, whereas ENDURANCE has chosen to support existing European MSR developers with their own MSR designs, to address their specific R&D requirements in terms of performance and safety demonstration.

MIMOSA, which is in its middle phase, has already delivered important results that have been described in this paper. ENDURANCE is in its early stages and will expand the MSR knowledge base on many aspects. Both MIMOSA and ENDURANCE strongly advocate for the continued prioritization of MSR research within the Euratom Research and Training Programme and for specific calls for proposals in the upcoming work programme that support the advancement of this innovative technology, which holds great promise for Europe's energy future. Such targeted support would enable the EU to build on the significant progress already achieved in MSR research and development.

Moreover, given the global interest in MSR technology–notably in the United States, international collaboration remains essential. Strengthening cross-border cooperation will facilitate knowledge sharing, accelerate advancements, and position Europe as a central player in MSR innovation. The development of a cohesive, global approach to MSR research should be a strategic objective for all stakeholders.

Acknowledgments

The authors are grateful for the funding provided by the European Union in the framework of the Euratom Research & Training Programme under Grant Agreement n° 101061142 and 101165896. Views and opinions expressed are however those of the authors only and do not necessarily reflect those of the European Union or EC-Euratom. Neither the European Union nor EC-Euratom can be held responsible for them. The authors are also very grateful to all the contributors to the MIMOSA and ENDURANCE projects.

The authors are grateful for the funding provided by the European Union in the framework of the Euratom Research & Training Programme under Grant Agreement n° 101061142 and 101165896. Views and opinions expressed are however those of the authors only and do not necessarily reflect those of the European Union or EC-Euratom. Neither the European Union nor EC-Euratom can be held responsible for them. The authors are also very grateful to all the contributors to the MIMOSA and ENDURANCE projects.

Conflicts of interest

The authors certify that they have no conflict of interest in connection with this article.

Data availability statement

The results from the neutronic calculations within the MIMOSA project are stored by Research Centre Řež (CVR) and will be made available upon request.

Author contribution statement

Conceptualization, S. Lorenzi, S. Deanesi, I. Morlaes and E. Guillaut; Original Draft Preparation, S. Lorenzi, S. Deanesi, I. Morlaes and E. Guillaut; Writing for ENDURANCE, S. Lorenzi, S. Deanesi; S. Dulla, N. Girault, J.M. Hamy, J. Krepel, P. Rubiolo; A. Smith, E. Merle; Writing for MIMOSA, I. Morlaes, E. Guillaut, L. Van den Durpel, A. Smith, D.C. Visser, E. Losa, J. Ocadiz Flores, E. Capelli, S. Delpech, L. Clot, E. Merle, A. Laureau, L. Giot, Review & Editing, S. Deanesi and C. Marozzi; Supervision, E. Guillaut.

Glossary

BEPU Best Estimate Plus Uncertainty

CTE Critical Technology Element

EU European Union

HFR High Flux Reactor

JRC Joint Research Centre

LWR Light Water Reactor

MOx Mixed Oxide

PIE Post-Irradiation Examination

PIM Polarisable Ion Model

PIRT Phenomena Identification Ranking Table

REPU Reprocessed Uranium

SNF Spent Nuclear Fuel

TAR Target Accuracy Requirement

TRL Technology Readiness Level

References

- https://single-market-economy.ec.europa.eu/industry/industrial-alliances/european-industrial-alliance-small-modular-reactors_en [Google Scholar]

- http://samofar.eu/ [Google Scholar]

- https://samosafer.eu/ [Google Scholar]

- https://www.mimosa-euratom.eu/ [Google Scholar]

- https://www.endurance-msr-project.eu/ [Google Scholar]

- O. Beneš, R.J.M. Konings, J. Chem. Thermodyn. 41, 1086 (2009) [CrossRef] [Google Scholar]

- O. Beneš, R.J.M. Konings, Thermodynamic evaluation of the NaCl-MgCl2-UCl3-PuCl3 system, J. Nucl. Mater. 375, 202 (2008) [CrossRef] [Google Scholar]

- E. Capelli, O. Beneš, R.J.M. Konings, J. Nucl. Mater. 501, 238 (2018) [CrossRef] [Google Scholar]

- A. Tosolin, P. Souček, O. Beneš, L. Luzzi, R.J.M. Konings, J. Nucl. Mater. 503, 171 (2018) [CrossRef] [Google Scholar]

- T. Dumaire, J.A. Ocadiz-Flores, R.J.M. Konings, A.L. Smith, A promising fuel for fast neutron spectrum Molten Salt Reactor: NaCl-ThCl4-PuCl3, Calphad 79, 102496 (2022) [CrossRef] [Google Scholar]

- R. Chieu, et al., Round Robin Measurements of Molten Salt Properties for a Common Batch of LiF-NaF-KF (FliNaK) and NaCl-KCl Eutectic Mixtures, Nuclear and Chemical Engineering Data (paper in preparation) [Google Scholar]