| Issue |

EPJ Nuclear Sci. Technol.

Volume 11, 2025

Euratom Research and Training in 2025: ‘Challenges, achievements and future perspectives’, edited by Roger Garbil, Seif Ben Hadj Hassine, Patrick Blaise, and Christophe Girold

|

|

|---|---|---|

| Article Number | 33 | |

| Number of page(s) | 13 | |

| DOI | https://doi.org/10.1051/epjn/2025023 | |

| Published online | 07 July 2025 | |

https://doi.org/10.1051/epjn/2025023

Review Article

Main goals and research outcomes of the EU Projects ELSMOR, McSAFER, and EASI-SMR: regulatory, experimental and analytical safety-related investigations

1

VTT Technical Centre of Finland ltd, Kivimiehentie 3, 02044 Espoo, Finland

2

Karlsruhe Institute of Technology (KIT), Hermann-vom-Helmholtz-Platz-1, 76244 Eggenstein-Leopoldshafen, Germany

3

EDF R&D, 6 quai Wattier, 78400 Chatou, France

* e-mail: ville.tulkki@vtt.fi

Received:

11

November

2024

Received in final form:

3

March

2025

Accepted:

23

April

2025

Published online: 7 July 2025

Small modular reactors are being developed globally with first new builds being planned within a decade. The most near-term designs are based on light water reactor technologies. While the fundamental technology is well known, the designs aim to utilize passive safety functions and simplifies systems to drive down costs. The correct operation of these functions must be ensured for these new nuclear reactors to be licensed in Europe. This paper discusses three projects funded by Euratom Research and Training programme: ELSMOR, McSAFER, and EASI-SMR.

In this paper, the main goals and selected outcomes of two European research projects that finished some months ago will be presented and discussed. In addition, the main goals and the research program of the EASI-SMR project will be described.

© V. Tulkki et al., Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1. Introduction

A large number of water-cooled Small modular reactors (SMRs) are being developed not only for electricity but also e.g., for process heating, water desalination, hydrogen. The first new builds are planned within a decade from now. At present, two main trends can be observed: innovative SMR concepts with integrated Reactor Pressure Vessel (RPV), where pumps, heat exchangers, and pressurizer are located in the RPV such as the SMART, NuScale, CAREM, and SMR-concepts based on proven LWR-technologies such as the AP-300, the CAP-100, BWRX-300, NUWARD SMR, and Rolls-Royce SMR. While the fundamental technology is well known, the designs aim to utilize passive safety functions and simplifies systems to drive down costs. One of the common features is the compact core with higher heterogeneity than the one of large LWRs, and an increased number of fuel rods containing burnable absorbers. Different number of heat exchangers of helical-coiled design are foreseen e.g., six for SMART, 12 for CAREM and 2 for NuScale. Recently, the LDR-50 SMR for process heat production at low temperature was developed by VTT. The different SMR-designs are equipped with passive safety systems to remove the residual heat in the short and long term in case of accidents. Hence, the different European projects are being funded by the EU with the goal of study the potential gaps in European competences for assessing the safety of light water SMRs (H2020 ELSMOR), to investigate experimentally safety-relevant phenomena and performing comparative analysis of different safety analysis tools for the analysis of core transients and plant transients (H2020 McSAFER) and to ensure the highest level of safety of LW-SMRs based on passive systems, assess the safety impact of LW-SMRs designs’ specificities and address regulatory and societal challenges towards the deployment of SMRs in Europe (EASI-SMR).

This paper discusses the main research goals and main outcomes of ELSMOR and McSAFER, which was finalized some months ago, and the research goals of the just started Horizon Europe Project EASI-SMR.

2. ELSMOR

The ELSMOR project [1] aims to enhance the European capability to assess and develop the innovative SMR concepts and their novel safety features. The work aims to investigate the safety of the Light Water Small Modular Reactors holistically as well as to drill down in set of topics identified by the consortium to be the most vital in ensuring the compliance of the future SMRs to the safety objectives as established by the amended Directive 2009/71/Euratom. Figure 1 depicts the organizational structure of the project. The initial work consisted of a review improvements proposed by various SMR designs and the applicability of European regulations for them (WP1), followed by in-depth investigations of various safety relevant issues and development of safety case methodology suitable for LW-SMRs (WP2). The passive safety functions of SMRs were investigated in WP3 and WP4, with the aim of looking at functions similar to what was proposed for the French SMR design at the time. These investigations were combined in an example of the safety case in WP5.

|

Fig. 1. ELSMOR workflow and project consortium. |

2.1. Selected results

The project produced a state-of-the-art review of the proposed near term LW-SMRs and their proposed safety features. A methodology for safety analysis was developed for the innovative LW-SMRs based on the experience in both large reactor analysis methodology as well as the experience in implementing such high-level methodology for Generation IV reactors, which is elaborated in project deliverable “Overview of safety methodologies for innovative reactor designs, and proposal of a general methodology for LW-SMR” [2]. The proposed ELSMOR methodology is mainly derived from the insights provided by the SARGEN_IV project. These insights are complemented with the HARMONICS method to develop high-level safety goals into more concrete requirements in a systematic and hierarchical manner allowing to provide a framework for defining requirements of different level of detail and for documenting the results of different types of safety assessments.

Third and fourth work packages investigated the cooling related safety functions in more detail. For core cooling, experimental facility is to investigate the functioning of compact plate type heat exchangers was built at SIET. The facility is depicted in Figure 2. An experimental campaign was run [3], and some of the results are available on request at EC's STRESA (Storage of Thermal Reactor Safety Analysis data, https://storage-thermal-reactor-safety-analysis-data.jrc.ec.europa.eu/facilities) system.

|

Fig. 2. ELSMOR experimental facility at SIET [3]. The performance of steam generator in the middle of the figure (S-CSG) with various fractions of non-condensable gasses is of the interest. Water is electrically heated in the primary circuit and the steam quality is controlled in the steam-water separator, whereas the fraction of noncondensable gases is controlled on the secondary side. |

Last technical work package of ELSMOR investigated integrated safety assessment for design basis accidents as well as severe accidents. In order to enable this, a new E-SMR (“European/ELSMOR-SMR”) design dataset was created. The design was inspired by the early publicly available French SMR design, with some parts integrating elements from several other SMR designs. The aim of the dataset was to provide a starting point for investigating the French SMR for education and R&D purposes, as at the time only a limited amount of public data could be found. As it is, the E-SMR shares its safety philosophy with the early French SMR design, but the technical design differs. Some of the non-published data was supplemented with data from similar SMR designs that are publicly available, supported by engineering judgment and sensitivity analysis. The initial design was iterated during the ELSMOR project to fulfill some chosen safety goals for design basis accidents. The dataset describing the E-SMR [4] is shared through FAIRDATA with CC-BY-NC 4.0 license. The complementary report [5] of the dataset provides an example calculation of Station Black-Out (SBO) case.

The E-SMR describes an integral PWR in a submerged containment inside a pool, as schematically described in Figure 3. The design utilizes six parallel identical Compact Steam Generators (CSG) for normal operation, producing heat to secondary circuit, while two Safety Compact Steam Generators (SCG) are used for decay heat removal to the water wall during transient conditions. Figure 3 also depicts the simulation scheme where ‘CSG1’ and ‘CSG2’ represent the 3-3 CSGs while ‘SCSG’ denotes the two safety heat exchangers. The right hand side of the figure provides the same information in a schematic way that was implemented in the simulation codes [5]. The schematic representation includes the static boundary conditions used in the simulations.

|

Fig. 3. Image of E-SMR design and schematic description of the primary circuit with Lower and Upper plenum (LP, UP), Pressurizer (PRZ), CSGs (simulated with boundary conditions BC), and SCSGs. |

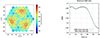

The SBO example case described in the model report [5] provides a set of initial boundary conditions as well as some reference results simulated with APROS code by VTT. The temperatures and pressures decrease initially fast, but the pressure and temperature gradients decay after a few hours, leading to flow instabilities as the driving forces of the passive system are reduced. Figure 4 describes the containment atmosphere (left) and water pool (right) temperature evolution during the 72 hours after the onset of the transient. Water pool features strong temperature stratification, and the top of the pool is near boiling-point at the end of the 72-hour period. However, the temperatures at the bottom of the pool and the inlet of the safety condenser (P-COND) have not varied much, ensuring the efficient removal of the decay heat. In case of the containment, the passive heat removal system heating became quite notable in the late section of the simulation, despite the 50 mm insulation blanket enveloping the P-COND and its adjacent piping. The results demonstrate that the safety approach adopted by the French SMR concept at the time of analysis (2022) could provide long-term core cooling function, and demonstrate the reliance of passive systems for the temperature and pressure differences to drive the safety function. However, as the SMR design was recently redone, the simulation model does not represent the current design.

|

Fig. 4. Containment atmosphere (left) and water pool (right) temperature evolution during the SBO scenario. |

3. McSAFER

The McSAFER project [6], was focused on experimental and numerical investigations for the safety evaluation of water-cooled SMRs such as NuScale, SMART, CAREM and F-SMR. It started in September 2020 and ended in February 2024 and consists of 13 partners from universities, TSOs, research organizations, and industry. It is organized in four technical work packages in addition to one for the management and another one for dissemination, communication, and exploitation, Figure 5.

|

Fig. 5. McSAFER consortium members (left) and Work packages (right). |

3.1. Research goals

The main research goals were to advance the methods for safety evaluation of water-cooled SMRs and to provide experimental data of safety-relevant phenomena in the core and integrated reactor pressure vessel (RPV). The experimental program consisted in test series at three European experimental facilities e.g., MOTEL at LUT, HWAT at KTH and COSMOS-S at KIT [7]. The experiments covered safety-relevant phenomena such as the cross-flow in the core, the performance of the helical-coiled heat exchanger, forced and natural circulation and its transition, etc. The data was used for the validation of thermal hydraulic codes (CFD, subchannel and system thermal hydraulic codes). The numerical part was devoted to the analysis of the core behavior under normal and accidental conditions (REA, Cold water injection) of four SMR-designs (CAREM, NuScale, KSMR, and F-SMR) using both industry-like and advanced transport (deterministic and Monte Carlo) Multiphysics computational routes. The behavior of a NuScale core loaded with Accident Tolerant Fuel (ATF), which consists of U3Si2 as fuel and FeCrAl as cladding, fuel under REA-conditions was investigated with three different high-fidelity coupling of neutronic, thermo-mechanics and thermal hydraulic codes and the obtained results were compared to the ones predicted for a core loaded with UO2. Finally, selected accidental sequences such as the Steam Line Break for NuScale and SMART were analyzed with three different coupled code approaches including system thermal hydraulic codes and 3D nodal diffusion codes, system thermal hydraulic codes coupled with subchannel and 3D nodal diffusion codes, and system thermal hydraulic codes coupled with CFD and 3D nodal diffusion codes. This paper will present and discuss the main outcomes of the core and plant analysis using Multiphysics and multi-scale methods with emphasis on the capabilities and future improvements for a more realistic prediction of safety parameters of SMRs as well the potentials of the methods for the analysis of transients in nuclear power plants of Gen-2 and -3.

3.2. Selected results

In this subchapter, selected results of the large research outcome of the McSAFER-project are shortly described. It is worth to mention that all public deliverables and published papers are stored and publicly available at this repository: https://zenodo.org/communities/mcsafer/. New experimental data on safety-relevant phenomena obtained at MOTEL [8], HWAT [9], and COSMOS-H [10] facilities: MOTEL tests focused on the study of the helical coil steam generator performance when performing steady state tests at different re power levels e.g., 250 kW, 500 kW, 750 kW, and 1 MW (first test) as well as 75 kW, 100 kW, 125 kW, and 150 kW (second test). The steam generator is equipped with 80 thermocouples, where five thermocouples are located along the tube length of steam generator tube [9]. MOTEL crossflow tests [10] devoted to investigating the mixing between core subchannels for uniform and nonuniform radial and axial power distributions within the core. These test series was also subdivided into two parts: experiments with an even radial core power distribution and experiments with a skewed radial core power distribution. The core consists of 212 temperature measurement points located in the heater rods and measurement rods at different axial levels.

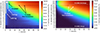

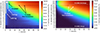

The validation of CFD [7], system [11], and subchannel [12] thermal hydraulics were performed once data of the different facilities became available. In Figure 6 (left), a comparison of the predicted temperature of the Steam Generator (SG) tube along the elevation for four power levels with the measured data is shown. An excellent agreement is observed between data and predictions. Figure 6 (right), shows a very good agreement of the coolant temperature along the core height predicted by ANSYS CFX with the measured one for the cross-flow test at the location-14.

|

Fig. 6. MOTEL: comparison of the coolant temperature measured along the axial elevation of the steam generator primary side with the one predicted by FLUENT (left) and the comparison of the measured coolant temperature at the radial location-14 along the core height with the one predicted by ANSYS-CFX (right). |

HWAT is a high-pressure, high-temperature water loop for investigation of two-phase flows equipped with an electrically heated test section (heated riser), a condenser, preheater, and a canned pump [13]. The focus of the first test series was transients from forced to natural circulation. In total 24 tests were performed. The boundary conditions such as pressure, flow rate and riser inlet temperature are kept constant while the riser power is increased step-wise with small increments. Data for the characterization of the flow at the riser outlet (local temperature, dynamic pressure and void) and for the thermal hydraulic performance of the condenser and for the detection of CHF-phenomena was measured [7, 13]. The focus of the second test series done in April-March 2024 was transients such as LOCA, Loss of Heat Sink (LOHS), power transients under natural circulation conditions as well as transients initiated by the perturbation of parameters in the primary, secondary and tertiary circuits [14]. It consists of three loops, an auxiliary system, a differential pressure measurement setup, and integrates four components that simulate a reactor core, a pressurizer (one per each loop), a steam generator and a PRHR (Passive Residual Heat Removal) pool. Typical HWAT-parameter ranges are the following: primary/secondary pressure (9–15 MPa/3.5–7 MPa), mass flow rate (0.3–0.5/0.05–0.15 kg/s), and power for the forced convection (80 kW) and natural convection (20–25 kW). The first group of tests are named commissioning and model calibration tests (TG01) and transients (TG02). In total seven TG01 and nine TG02 tests were performed. This data could not be used for code validation anymore in McSAFER since the measurements were done at the end of the project.

HWAT data of the first test series (test Nr. 32) was used for the validation of CFD-codes. In Figure 7 the comparison of the void fraction (left) measured along the tube radius and wall temperature (right) measured along tube elevation is compared with the OpenFOAM-predictions. It is worth noting that a tube of 1cm diameter and 4m height is located in the test section. It can be observed that near the wall (left figure), the void fraction is good agreement with the data and this agreement is getting worse above a radius larger than 0.005 m. On the other hand, the wall temperature predicted by OpenFOAM at the upper part of the test section (tube) is in a good agreement with the measured values [7, 15]. It was measured using a multi-sensor probe device located at the top of the test section, specifically developed for this purpose.

|

Fig. 7. HWAT: comparison of predicted and measured void fraction along the radius of the test tube (left) and comparison of the tube wall temperature as predicted and measured at the upper part of the test section. The predictions were done with OpenFOAM. |

The COSMOS-H (Critical Heat Flux on Smooth and Modified Surfaces - High Pressure Loop) is built for the detailed investigation of thermal hydraulic phenomena, such as convective heat transfer, nucleate boiling and CHF, for a single or up to five rods [16]. Due to delays of supply of important parts for COSMOS-H during COVID-pandemic, merely the commissioning tests were performed with success. During the first test campaigns leakages, and corrosion issues appeared at the facility entrance so that five CHF-values could be measured which were corrupted by the coolant quality. Such data is not appropriate for code validation.

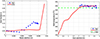

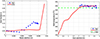

Transient analysis of different water-cooled SMR-cores with different computational routes: two transients core transients were investigated for four core designs with different computational approaches: industry-like approach base on 3D nodal diffusion with 1D thermal hydraulics, Low-order transport coupled with subchannel codes, and Multiphysics codes base on Monte Carlo and subchannel codes [17]. A cold-water injection (CWI) transient was simulated for CAREM and F-SMR cores. For the first time, a long CWI-transient lasting for 50 s was simulated with the high-fidelity code Serpent/Subchanflow obtaining novel results [18]. Figure 8 shows the 2D fuel temperature distribution of the core at transient begin (axial level 14 (left)), where the hottest and coldest pin can be identified while on the right side, the DNBR predicted by the coupled code is shown.

|

Fig. 8. CAREM CWI transient analysed with Serpent2/Subchanflow: predicted pin-wise fuel temperature in the core (left) and DNBR (right). |

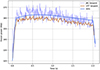

A rod ejection accident (REA) was analyzed for the KSMR and NuScale cores using high fidelity coupled codes [18]. The NuScale REA for a core loaded with normal and ATF-fuel was analyzed with three different coupling approaches including neutronic, thermal hydraulic and thermo-mechanics. VTT used the Python/socket-based coupling of Serpent2/Subchanflow/Transuranus, JRC KA applied the ICoCo-based coupling of Serpent2 /Subchanflow/Transuranus and LUT used a Perl-base supervisor for the three codes with a tight coupling between Subchanflow and Transuranus. Figure 9 shows the comparison of the fission power predicted with the high-fidelity tools (JRC KA and VTT) and the one predicted by the nodal diffusion solver ANTS of VTT. Similar trends are predicted by the three approaches. The nodal diffusion code ANTS predicts higher values than the ones of VTT and lower than the ones of JRC KA. The large oscillations of the JRC KA solution are due to the quite small number of cycles and histories used compared to VTT [19].

|

Fig. 9. Comparison of the fission power evolution after REA of the NuScale core as predicted by two high-fidelity solutions and one diffusion solver (ANTS). |

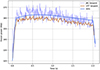

Multi-physics/-scale Analysis of water-cooled SMR Plant Transients: the main steam line break (MSLB) transient was analysed for the SMART NuScale [20] reactors using multi-scale/-physics computational routes that comprises industry-like tools and advanced tools under development such as the coupling of system thermal hydraulic/3D neutron kinetics/subchannel codes and system thermal hydraulic/3D neutron kinetics/CFD codes. Three novel coupled codes were partly developed and applied here: the ICoCo-based coupling of TRACE/PARCS/OpenFOAM (KIT) and ATHLET/DYN3D/TrioCFD (HZDR), the Python/socket-based coupling implemented in the Kraken Framework named TRACE/ANTS/OpenFOAM (VTT) and the user-defined coupling of ATHLET/DYN3D/FLUENT (UJV). In [21] and [20] the details of the results obtained with the multi-physics/ -scale computational routes listed before can be found. In general, it can be stated that the evolution of global parameters such as power, reactivity, etc. are qualitatively similar. Quantitatively, some differences exist among the different solutions due to differences in the coupling approaches, in the steady state conditions predicted by each code, the break modelling and last but not least the modelling of the passive heat removal system, especially the condensation inside the tubes and also the heat transfer in the helical-coiled steam generator tubes. Thanks to the use of CFD-tools to describe the phenomena in the down comer and lower plenum, the detailed 3d distributions of key parameters such as coolant temperature, velocities, pressures in the computational regions as well as at the core inlet plena could be predicted during the evolution of the Steam Line Break transient. It could be demonstrated that the coolant temperature is very good mixed at the core entrance for the NuScale and SMART designs minimizing the risk for non-symmetrical transient.

4. EASI-SMR

The EASI-SMR (Ensuring Assessment of Safety Innovation for SMR) project will address the various technological challenges linked to the safety of the main innovations in light water SMRs that have been identified within the R&D roadmap of the EU SMR pre-partnership [22] with a specific focus on passive systems (Fig. 10). The work aims to help with the licensing and deployment of European light water SMRs, in particular the NUWARD SMR developed by NUWARD and the LDR-50 developed by Steady Energy. The EDF-led consortium includes 38 partners from 16 European countries and the total budget for the project is €24M, including €15M in grants over 4 years. The project was launched in September 2024 and will end in August 2028.

|

Fig. 10. EASI-SMR project consortium. |

4.1. Research goals

LW-SMRs rely on well-proven technologies from currently operating LW reactors, as well as on upcoming innovations to strengthen safety and increase economic competitiveness. The EASI-SMR project will focus on the most challenging issues for the deployment of safe LWR-SMR's in the EU by early next decade: passive safety systems, human and organisation factors at stake in LW-SMRs operation (multi-units operation), core physics of boron free cores, co-generation and hybridisation, additive manufacturing to improve compactness of nuclear steam supply system, harmonisation of licensing and acceptability. Even if light water SMR benefit from the large light water reactor operation, currently no SMRs are in operation in Europe and the operational experience on passive systems is quite limited. Within this regard, EASI-SMR project will provide new and unique experimental data for characterizing passive system operation and for code validation.

The expected impacts of the project are:

-

increased knowledge of passive system physics. In particular, separate effect tests will be developed in order to improve the models of thermal hydraulic system codes.

-

Enhanced safety assessment methodologies for LW-SMRs used in the licensing process, particularly for the quantification of the reliability of passive safety systems.

-

Improved Technology Readiness Level and regulatory approval for nuclear components fabricated by additive manufacturing techniques.

-

Support for the selection of the appropriate core design for water-cooled SMRs under development.

-

Support a shared and coherent approach among regulators regarding safety requirements for LW-SMRs.

-

Better understanding and acceptance of LW-SMRs in the EU.

The safety functions covered by the studied passive systems are:

-

heat removal from the reactor core, the containment and via cooling chains.

-

Replenishing coolant.

-

Pressure and temperature limitation in the reactor system and in the containment.

4.2. Work outlook

The R&D roadmap of the European SMR pre-partnership identified several R&D gaps among 7 topics: core and fuel, NSSS and its internals, passive safety systems, severe accidents, modularization, human factors and use beyond electricity. This roadmap has been revised with a special focus on passive systems to structure the EASI-SMR project into 7 technical work packages. Figure 11 shows the interactions between the work packages, their activities, and outcomes.

|

Fig. 11. Overall organization of EASI-SMR activities. |

The work of WP1 on acceptability and licensing aims to facilitate this deployment, by:

-

providing guideline on harmonized licensing, starting from the work of the HARMONISE project [23] and involving regulator active in SMR licensing.

-

Ensuring waste management system are compatible with LW-SMR by connecting with EURAD-2 [24] project to share LW-SMR specificities to the waste management community.

-

Creating manuals for stakeholder engagement, to help vendor and utilities with them interaction with the local communities.

-

Clarifying the co-location problematic by determining Emergency Planning Zone (EPZ) size with calculations using ELSMOR methodology and data from WP7.

-

Integrating SMR in the hybrid energy system. Simulation of thermohydraulic transients will analyses the impact of industrial heat production and district heating on the LW-SMR safety. The SMR input deck, which was conceived by the ELSMOR project (E-SMR), will be utilized in this task. The requirement on electrical grid for safe and economical deployment of SMR will also be assessed.

-

Performing safety and security analysis on Ukrainian war to search for lessons on improving the resilience of LW-SMR.

The safety assessment of passive systems relies on calculations codes that must be qualified with a strong experimental basis. To complement past experimental projects, and in particular the ELSMOR project dedicated to SMR and PASTELS dedicated to passive systems, a set of 9 experiments will be performed in WP2. The experimental program of WP2 illustrated in Figure 12 is established to cover to entire chain of heat removal from the core to ultimate heat sink, through Steam Generator (SG) and safety condenser (SACO) for DBC (design basis conditions) and DEC-A (design extension conditions: operating conditions with multiple faults) and through the vessel and the containment for DEC-B (design extension conditions: operating conditions with core meltdown). The 9 experiments in the test program are detailed below by physical phenomenon of interest.

|

Fig. 12. The nine experiments of WP2 with their location in the power removal chain. |

The physical phenomena of interest are:

-

steam condensation in a SACO tube: COSAC will cover the full range of steam pressures and temperatures likely to be generated in an SMR safety loop and PRECISE will provide complementary high resolution data for CFD validation (film condensation with non-condensable gases).

-

Single-phase and two-phase natural circulation:

-

IVR: natural convection outside the RPV for boiling (critical heat flux measurement) and thermosiphon configuration.

-

PANDA: natural convention around a 3rd barrier containment immerged in a large water pool during a postulated severe accident.

-

-

Natural circulation in a large loop: the ALCINA test facility will determine the pressure drops and heat exchanges in a large two-phase flow thermosiphon loop with a hot and cold source.

-

Thermal exchange in a plate heat exchanger: the purpose of the ECRINS loop is to investigate steam condensation in narrow channels (hydraulic diameter < 3mm) in presence of non-condensable gases.

-

Gravity injection from a gravity accumulator passive system: the GRADAC experiment consists in reproducing the initial pressurization phase of this component, until equilibrium is reached. The condensation of injected steam on the cold free liquid surface will also be studied and modelled, as well the thermal absorption of the upper metal walls.

The FHEASIK CET is representative of the Emergency core cooling system (ECCS) on Steady Energy's LDR-50 reactor. This is a passive heat transfer route from the reactor pressure vessel, through the partially water-filled containment to the reactor pool. ECCS transfers heat efficiently through the water-filled elevations but also the gas-filled elevations participate significantly. Localized, heat transfer increasing evaporation-condensation cycle is expected to form into the containment. The FHEASIK test facility focuses on the partially water-filled containment and its interaction with the reactor pool.

The CET ELSMOR II will pursue a set of experimental tests to extend the work done during the ELSMOR project, by extending the modelling of the experimental loop, now limited to the secondary two-phase loop. The ELSMOR test facility in SIET characterizes the operation of a safety condenser loop as decay heat removal and primary circuit depressurization system present in the European integral E-SMR. Phase 1 will concern the realization of LOOP or SBO type pseudo transients to develop and validate the PSA methodology adapted to the passive systems of WP4. The models developed in WP3 will be used to quantify the functional failure rate of passive systems. Phase 2, outside the benchmark, will consist in studying the two-phase operation of a plate heat exchanger, with a sensitivity study on the concentration of incondensable matter on the primary circuit side.

Based on the experimental results provided by WP2, eight benchmark exercises will be proposed in WP3, having as a target to assess the capability of the codes to predict specific phenomena, investigated in ad hoc SETF, and identified the reason of possible discrepancies (code modelling deficiencies, users not experienced with passive system modelling, etc).

Codes used in WP3 are the following:

-

severe Accident codes: MAAP [28](EDF version), ASTEC [29], AC2 [30];

-

CFD codes: code_saturne/neptune_cfd [31], ContainmentFOAM [32], OpenFOAM [33], StarCCM+ [34].

The results of the benchmark will then be used to identify the need in terms of code development and validation, as well as to develop user guidelines on passive system modelling.

In addition, WP3 has as a target to develop a feasibility study of a large scale IETF for contributing to thermal-hydraulically characterize LW-SMR designs, with particular emphasis to the European SMR designs characteristics. This activity can benefit of the work done already in ELSMOR project for the E-SMR.

The safety assessment of passive systems will be studied in WP4 with probabilistic and deterministic methodologies. The Probabilistic Safety Assessment (PSA) needs realistic probabilities of failure for passive systems. The additional calculations required for the quantification of the functional failure rate will use assessed codes of WP3. The long-term transient SBO scenario in the ELSMOR II facility will be considered as reference to develop and validate the PSA model adapted to Passive systems. In addition to the reliability of passive systems, Human Reliability Analysis (HRA) will be performed for human actions involving passive systems, using the insights on operator behaviour from WP5. Methodological work on multi-unit PSA will also be done in this work package to provide guidelines for PSA modelling of several units of SMR.

In deterministic safety assessment, the challenge is to assess reasonably conservative characteristics of passive systems that does not lead to a system undue oversizing. A method will therefore be proposed to assess these characteristics.

The main objective of WP5 is to create new knowledge about the safety of LW-SMRs from the point of view of human and organizational factors (HOF). The use of passive safety system in LW-SMR and multi-units operation in the same control room will affect the way operators monitor and pilot the SMR. Scenarios relevant to these issues will be played on the SMR simulator of IFE in Halden (Norway) with a team of NPP operators. The experiment will provide lessons learned for LW-SMR designers, as well as insights for the HRA activity in WP3.

SMR rely on modularization and the development of a dedicated supply chain for their economic competitiveness. A socio-technical analysis of potential SMR supply chain will be realized to identify the potential safety issues. The compactness of SMRs may create maintenance difficulties. Human & organizational analysis will be done on these topics to provide guideline for efficient and safe maintenance of SMR.

In addition, the behavior of SMR operators during cyber-security attack will be assessed through experiments on the IFE simulator and cybersecurity center to improve the robustness of procedures and organizations.

Within WP6, actions devoted to the qualification of SG mockups fabricated with additive manufacturing techniques will be carried out. Advance manufacturing as additive manufacturing, or 3D printing, have significant advantages compared to conventional manufacturing methods: production of components with complex geometries much faster and with higher performance compared to conventional manufacturing.

A big mock-up (1 to 2m) of a tube-type GV design with tube sheet will be fabricated with Inconel 625 and DED-LB/Mp) methodology, focusing on the tube plates area. Other small mockups representative of advances SG designs (compact SG with narrow channels) will be fabricated by L-PBF with Inconel 625 and alloy 800.

Mock-ups will be produced, and destructive and non-destructive characterization will be performed. A methodology report on elaboration of a guidelines for pre-qualification of AM heat exchanger will then be prepared based on the experimental results. These activities will feed into ASME and AFCEN committees

In the McSAFER project, the behaviour of four SMR-core designs and representative transients were analysed with four different computational routes including industry-like codes, deterministic transport and Monte Carlo coupled with 1D and subchannel thermal hydraulics. WP7 aims to pursue the findings of McSAFER with the PRATIC and the LDR-lite boron free cores. On both cores, reactivity control during the depletion cycles works without boron in the coolant. Moreover, the estimation of the nuclide inventories and vectors of spent fuel from the operation of boron-free SMR-cores is an important aspect that needs investigations and comparisons with the ones of a large LWR-core. Isotopic composition of the cores will be used for EPZ calculations in WP1.

5. Discussion

ELSMOR work concluded that on the high level, the requirements, tools, and methodologies intended for safety analyses of light water SMRs are suitable for their purpose, however several open questions were identified. These included reliability of passive systems, multi-unit operations, and human and operational issues for SMRs. These open questions were input for the European pre-partnership SMR work, which in part created the framework for the EASI-SMR project.

For passive systems research, ELSMOR created test facility at SIET and ran test with compact heat exchangers, and these tests will be continued in EASI-SMR with SBO type pseudo transients and two-phase flow operation of the plate heat exchanger with a sensitivity study on the concentration of non-condensable gases on the primary side. E-SMR database representing a prototypical SMR design was created in ELSMOR, and it will adapted in EASI-SMR for future safety case studies.

McSAFER performed tests dedicated to cross-flow in the core, performance of helical-coiled heat exchanges, transition from forced to natural circulation and vice-versa in experimental facilities considering thermal hydraulic conditions and geometrical specificities of water-cooled SMRs. Hence, experimental data was generated for validation of safety analysis tools. In addition, the behavior of SMR-cores loaded with fresh fuel with boron (NuScale) and without boron (CAREM, F-SMR, KSMR) were extensively investigated with different numerical approaches from industry-like, research tools and advanced high-fidelity based on Monte Carlo coupled with subchannel thermal hydraulics. In the Work Package 7 of the EASI-SMR project, the static, depletion, and transient behavior of two boron free-SMR-core (PRATIC and LDR-50) will be investigated with different approaches including high-fidelity methods as continuation of McSAFER. The complementary analysis of design basis accidents of water-cooled SMRs performed in ELSMOR (E-SMR) and McSAFER (NuScale, SMART) using both system thermal hydraulic codes but also new developments based on multi-scale/-physics safety analysis tools - that includes 3D nodal solvers, subchannel and CFD coupled with system thermal hydraulic codes- are very important to describe more precisely the 3D thermal hydraulic phenomena of small cores, and SMR-plants equipped with integrated-RPV and passive heat removal systems.

In addition to continuing the activities of the ELSMOR and MCSAFER projects on acceptability, licensing, safety study tools and neutron modeling of boron-free cores, the EASI-SMR project will address most of the R&D gaps identified in the R&D roadmap of the European SMR pre-partnership. An impressive test program on passive systems will provide validation data for safety calculation codes and improve reliability methods for passive systems. HOF at stake in LW-SMRs operation will be studied and advanced manufacturing of specific component will be addressed.

Small modular reactors hold promise on contributing to European competitiveness and light water technology is the one most likely adopted for near future construction. ELSMOR, McSAFER, and EASI-SMR advance European competences and understanding in assessing the safety of these light water SMRs, and aim to enable their adoption in Europe. All these projects contribute also to the experimental database generation for the validation of safety-relevant phenomena of water-cooled SMRs. These investigations are in line with the European SMR Industrial Alliance that aims to facilitate the first European SMR projects.

While on general level the capabilities to assess light water SMRs are sufficient, there are some specific issues especially when it comes to novel safety functions that are being proposed. These need to be verified, as well as the high-fidelity tools, with new and improved data.

Acknowledgments

The authors would like to acknowledge the work of and thank all the participants of McSAFER, ELSMOR, and EASI-SMR projects.

Funding

ELSMOR received funding from the Euratom research and training programme 2014-2018 under Grant Agreement No. 847553. The authors thank the Horizon 2020 McSAFER project for the funding from the Euratom research and training programme 2019-2020 under the grant agreement No 945063. EASI-SMR has received funding from the Euratom research and training programme 2023-25-NRT-01-02 under grant agreement No 101164810.

Conflicts of interest

Authors VT, VS, and NS certify that they have no financial conflicts of interest (eg., consultancies, stock ownership, equity interest, patent/licensing arrangements, etc.) in connection with this article.

Data availability statement

This article has no associated data generated and/or analyzed.

Author contribution statement

Individual contributions to chapters: on ELSMOR, VT; McSAFER, VS; EASI-SMR, NS. All authors contributed equally to the rest of the review article.

References

- ELSMOR, Towards European Licencing of Small Modular Reactors, EU, 1 September 2019, [Online], Available: https://cordis.europa.eu/project/id/847553/reporting/fr [Accessed 25 Mai 2022] [Google Scholar]

- S. Lansou et al., ELSMOR – towards European Licensing of Small Modular Reactors: Methodology recommendations for light-water small modular reactors safety assessment [version 2; peer review: 2 approved, 3 approved with reservations]., Open Res. Europe 3, 158 (2024) [CrossRef] [Google Scholar]

- R. Ferri, A. Achilli, C. Congiu, S. Marcianò, S. Gandolfi, M. Marengoni, A. Bersani, A.P. D’Entreves, ELSMOR European Project: Experimental Results on an Innovative Decay Heat Removal System Based on a Plate-Type Heat Exchanger, Sci. Technol. Nucl. Installations, Article ID 6672504 (2023) [Google Scholar]

- ELSMOR E-SMR dataset, https://doi.org/10.23729/474d23cf-60a7-4f78-9d6e-1e2d8633db4b [Google Scholar]

- F. Davelaar, N. Bakouta, A. Bersano, J. Bittan, S. Buchholz, C. Lombardo, A. Kaliatka, C. Liegeard, S. Lorenzi, K. Nikitin, M. Ricotti, M. Szogradi, M. Valinčius, E-SMR dataset description, ELSMOR Deliverable D5.2_public (2023) [Google Scholar]

- V.H. Sanchez-Espinoza, S. Gabriel, H. Suikkanen, J. Telkkä, V. Valtavirta, M. Bencik, S. Kliem, C. Queral, A. Farda, F. Abéguilé, P. Smith, P.V. Uffelen, L. Ammirabile, M. Seidl, C. Schneidesch, D. Grishchenko, H. Lestani, The H2020 McSAFER Project: Main goals, technical work, program, and status, Energies, 6348, 14 (2021) [Google Scholar]

- H. Suikkanen, J. Tellkä, V. Kouhia, S. Gabriel, G. Albrecht, W. Heiler, F. Heineken, M. Bencik, L. Vyskocil, V. Dolecek, C. Queral, K. Fernadez-Cosials, L. Rueda-Villegas, C. Schneidesch, Thermal Hydraulic Experiments and Code Validation for LWR SMRs within the European McSAFER Project: Overview of Activities and Current Status, in Intern. Conference NURETH-20. August., (Washington, D.C. USA, 2023) [Google Scholar]

- J. Telkkä, A. Räsänen, E. Kotro, H. Suikkanen, Results of the MOTEL Helical Coil Steam Generator Behaviour Experiments (D2.5) (McSAFER, Helsinki, 2021) [Google Scholar]

- D. Grishchenko, HWAT Experimental Setup and Test Matrix for First Test Series. D2.7 (McSAFER Project, Stockholm, 2021) [Google Scholar]

- S. Gabriel, G. Albrecht, W. Heiler, F. Heineken, COSMOS-H Experimental Setup and Tests (McSAFER. Deliverable Number 2.1, Karlsruhe, 2021) [Google Scholar]

- L. Rueda-Villegas, V. Sunkova, V. Dolecek, S. Gabriel, U. Imke, Validation of Subchannel Codes with the COSMOS-H and MOTEL experiments (McSAFER D2.12) (McSAFER, Bruessel, 2023) [Google Scholar]

- D. Grishchenko, A. Kipiela, H. Li, P. Kudinov, HWAT Results from the First Test Series (McSAFER D2.8) (McSAFER, Stockolm, 2024) [Google Scholar]

- J. Tellkä, H. Suikkanen, A. Räsänen, E. Kotro, Results of the MOTEL Transverse Flow Experiments. D2.6 (LUT, Laaperanda, 2022) [Google Scholar]

- M. Bencik, V. Sanchez, K. Zhang, N. Palmans, C. Queral, J. Sanchez-Torrijos, A. Garcia-Berrocal, L. Ammirabile, O. Parera-Villacampa, E. Diaz-Pescador, V. Jammot, K. Fernandez-Cosials, A. Grahn, L. Vyskocil, R. Meca, S. Kliem, Final Comparison of System Codes and Mutliscale Analysis (McSAFER D4.9) (McSAFER, Prague, 2024) [Google Scholar]

- D. Grishchenko, A. Kipiela, H. Li, M. Persson, P. Kudinov, HWAT Results From the Second Test Series (McSAFER D2.10) (McSAFER, Stockholm, 2024) [Google Scholar]

- K. Tielinen, J. Telkkä, E. Kotro, V. Kouhia, H. Suikkanen, Description of the MOTEL Facility and Instrumentation (McSAFER. Deliverable 2., Helsinki, 2021) [Google Scholar]

- D. Grishchenko, X. Wang, H. Li, P. Kudinov, HWAT Experimental Setup and Test Matrix for the Second Test Series (McSAFER D2.9) (McSAFER, Stockholm, 2022) [Google Scholar]

- E. Fridman, Y. Bilodid, M. Dalinger, H. Lestani, E. Lopasso, A. Weir, R.P. Salazar, J. Blanco, L. Mercatali, V. Sanchez, A. Farda, V. Valtavirta, A. Jambrina, M. Seidl, D.D. Meyer, H.F.R. Vocka, Stat-of-the-art Solutions for th Transient Scenarions in the Four SMR-cores. D3.4 (McSAFER, Karlsruhe, 2022) [Google Scholar]

- L. Mercatali, G. Huaccho, U. Imke, V. Sanchez-Espinoza, V. Valtavirta, P. Van-Uffelen, Z. Soti, H. Suikkanen, A. Charles, High-fidelity Solutions for the Transient Scenarios in the Three SMR-cores (McSAFER D3.8) (McSAFER, Karlsruhe, 2024) [Google Scholar]

- A. Grahn, S. Kliem, R. Meca, O. Petrášek, L. Vyskočil, V. Valtavirta, R. Tuominen, J.-P. Ikonen, R. Komu, Multiscale System/CFD Safety Analyses of NuScale Reactor System and Intercomparison Between Codes (McSafer D5.6) (McSAFER, Dresden, 2024) [Google Scholar]

- H. Suikkanen, V. Valtavirta, Z. Soti, Simulation of the ATF Core Transient Using High-fidelity Tools and Intercomparison with Results from T3.4 (non-ATF case) (McSAFER D3.11) (McSAFER, Helsinki, 2024) [Google Scholar]

- K. Zhang, V. Sanchez, J. Sanchez-Torrijos, Multi-Scale Thermal Hydraulics (TH) Analysis of a Steam Line Break (SLB) Accident for SMART with TRACE/PARCS/OpenFOAM (McSafer D5.5) (McSAFER, Karlsruhe, 2024) [Google Scholar]

- HARMONISE, Towards harmonisation in licensing of future nuclear power technologies in Europe, 2022-2025, Available: https://cordis.europa.eu/project/id/101061643 [Google Scholar]

- EURAD-2, European Partnership on Radioactive Waste Management – 2, 2024-2029, Available: https://cordis.europa.eu/project/id/101166718 [Google Scholar]

- CATHARE, Available: https://cathare.cea.fr/ [Google Scholar]

- APROS, Available: https://www.apros.fi/ [Google Scholar]

- SPECTRA, Available: https://www.ensuringnuclearperformance.com/producten/safe-operations/veiligheidsanalyses/spectra [Google Scholar]

- MAAP, Available: https://www.epri.com/research/products/3002012555 [Google Scholar]

- ASTEC, Available: https://en.irsn.fr/research/astec-software-system#::text=The%20ASTEC%20(Accident%20Source%20Term,outside%20the%20containment%20%5B1%5D [Google Scholar]

- AC2, Available: https://www.grs.de/en/research-and-assessment/reactor-safety/code-package-ac2 [Google Scholar]

- code_saturne/neptune_cfd, Available: https://www.code-saturne.org/cms/web/ [Google Scholar]

- ContainmentFOAM, Available: https://iffgit.fz-juelich.de/containmentfoam_developers/containmentfoam_of6 [Google Scholar]

- OpenFoam, Available: https://www.openfoam.com/documentation/guides/latest/doc/index.html [Google Scholar]

- StarCCM+, Available: https://plm.sw.siemens.com/en-US/simcenter/fluids-thermal-simulation/star-ccm/ [Google Scholar]

Cite this article as: Ville Tulkki, Victor Hugo Sanchez-Espinoza, Nicolas Sobecki. Main goals and research outcomes of the EU Projects ELSMOR, McSAFER, and EASI-SMR: regulatory, experimental and analytical safety-related investigations, EPJ Nuclear Sci. Technol. 11, 33 (2025). https://doi.org/10.1051/epjn/2025023.

All Figures

|

Fig. 1. ELSMOR workflow and project consortium. |

| In the text | |

|

Fig. 2. ELSMOR experimental facility at SIET [3]. The performance of steam generator in the middle of the figure (S-CSG) with various fractions of non-condensable gasses is of the interest. Water is electrically heated in the primary circuit and the steam quality is controlled in the steam-water separator, whereas the fraction of noncondensable gases is controlled on the secondary side. |

| In the text | |

|

Fig. 3. Image of E-SMR design and schematic description of the primary circuit with Lower and Upper plenum (LP, UP), Pressurizer (PRZ), CSGs (simulated with boundary conditions BC), and SCSGs. |

| In the text | |

|

Fig. 4. Containment atmosphere (left) and water pool (right) temperature evolution during the SBO scenario. |

| In the text | |

|

Fig. 5. McSAFER consortium members (left) and Work packages (right). |

| In the text | |

|

Fig. 6. MOTEL: comparison of the coolant temperature measured along the axial elevation of the steam generator primary side with the one predicted by FLUENT (left) and the comparison of the measured coolant temperature at the radial location-14 along the core height with the one predicted by ANSYS-CFX (right). |

| In the text | |

|

Fig. 7. HWAT: comparison of predicted and measured void fraction along the radius of the test tube (left) and comparison of the tube wall temperature as predicted and measured at the upper part of the test section. The predictions were done with OpenFOAM. |

| In the text | |

|

Fig. 8. CAREM CWI transient analysed with Serpent2/Subchanflow: predicted pin-wise fuel temperature in the core (left) and DNBR (right). |

| In the text | |

|

Fig. 9. Comparison of the fission power evolution after REA of the NuScale core as predicted by two high-fidelity solutions and one diffusion solver (ANTS). |

| In the text | |

|

Fig. 10. EASI-SMR project consortium. |

| In the text | |

|

Fig. 11. Overall organization of EASI-SMR activities. |

| In the text | |

|

Fig. 12. The nine experiments of WP2 with their location in the power removal chain. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.