Fig. 1

Download original image

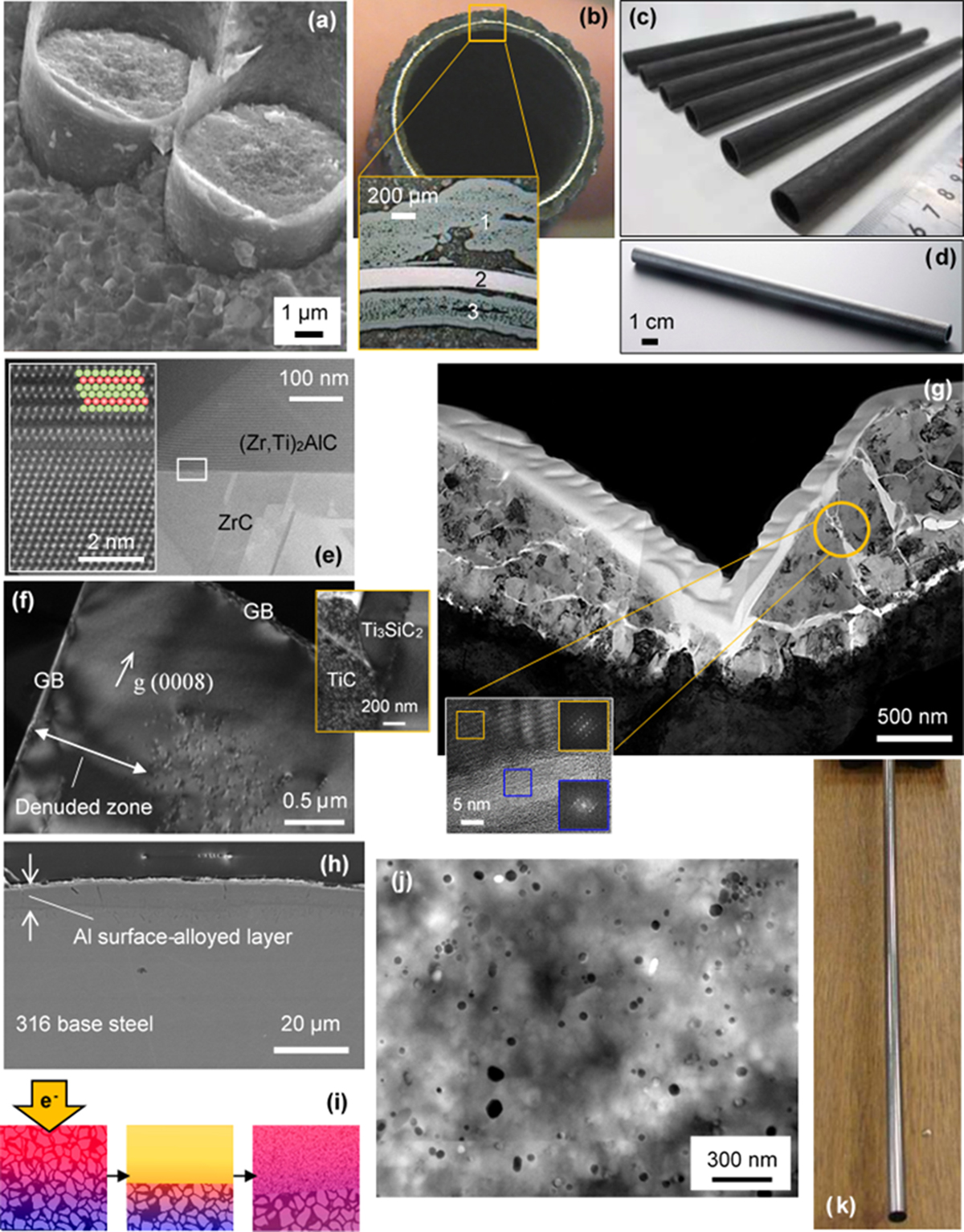

(a–d) SiC/SiC composite clads: (a,c) DEMO-NITE SiC/SiC fracture surface and tubes; (b,d) CEA “sandwich” SiC/SiC cross-section and tube. (e) STEM image of a (Zr,Ti)2AlC MAX phase grain next to a ZrC “impurity” grain. The magnified inset is a STEM image of the (Zr,Ti)2AlC/ZrC interface. (f) Neutron-irradiated Ti3SiC2 (∼735 °C, 3.4 dpa): defect-denuded zones are established next to grain boundaries (GBs) acting as potent defect “sinks”. The magnified inset shows more damage in the “impurity” TiC grain than in Ti3SiC2. (g) TEM images of a nano-impacted, ion-irradiated (150 dpa) Al2O3 coating: the crack-like features are filled with vitreous matter. (h) GESA Al surface-alloyed 316 L steel exposed to liquid LBE (10 000 h, 600 °C, C O ≈ 10−6 mass%). (i) GESA surface modification by an intense pulsed electron beam: volumetric heating → formation of a melt layer → restructured surface layer. (j) TEM image of a Fe-20Cr-5Al-0.5Ti-0.5Y2O3 alloy with nano-sized dispersoids. (k) Fe-14Cr ODS tube produced by CEA.

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.