| Issue |

EPJ Nuclear Sci. Technol.

Volume 2, 2016

|

|

|---|---|---|

| Article Number | 29 | |

| Number of page(s) | 12 | |

| DOI | https://doi.org/10.1051/epjn/2016022 | |

| Published online | 06 June 2016 | |

https://doi.org/10.1051/epjn/2016022

Regular Article

Three-component U-Pu-Th fuel for plutonium irradiation in heavy water reactors

1 Department of Materials Science and Engineering, University of Sheffield, Sir Robert Hadfield Building, Mappin Street, Sheffield, S1 3JD, UK

2 Nuclear-21.net, Waasmunster, Belgium

3 University of Sheffield, Sheffield, UK

4 University of Liverpool, Liverpool, UK

⁎ e-mail: rpeel@sheffield.ac.uk

Received:

6

October

2015

Received in final form:

15

March

2016

Accepted:

8

April

2016

Published online: 6 June 2016

This paper discusses concepts for three-component fuel bundles containing plutonium, uranium and thorium for use in pressurised heavy water reactors, and cases for and against implementation of such a nuclear energy system in the United Kingdom. Heavy water reactors are used extensively in Canada, and are deploying within India and China, whilst the UK is considering the use of heavy water reactors to manage its plutonium inventory of 140 tonnes. The UK heavy water reactor proposal uses a mixed oxide (MOX) fuel of plutonium in depleted uranium, within the enhanced CANDU-6 (EC-6) reactor. This work proposes an alternative heterogeneous fuel concept based on the same reactor and CANFLEX fuel bundle, with eight large-diameter fuel elements loaded with natural thorium oxide and 35 small-diameter fuel elements loaded with a MOX of plutonium and reprocessed uranium stocks from UK MAGNOX and AGR reactors. Indicative neutronic calculations suggest that such a fuel would be neutronically feasible. A similar MOX may alternatively be fabricated from reprocessed <5% enriched light water reactor fuel, such as the fuel of the AREVA EPR reactor, to consume newly produced plutonium from reprocessing, similar to the DUPIC (direct use of PWR fuel in CANDU) process.

© R. Peel et al., published by EDP Sciences, 2016

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

The aim of this work was to perform a screening study into alternative fuel compositions for pressurised heavy water reactors (PHWR), which would incorporate plutonium and reprocessed and/or depleted uranium alongside thorium. The outcomes of the screening study will be used to inform further development work into the feasibility of such fuels.

The United Kingdom holds a large inventory of separated plutonium. Plutonium may be used in the manufacture of nuclear weapon fissile cores, with a critical mass of approximately 10 kg when assembled from a suitable isotopic mixture. When current reprocessing contracts end in 2018, the quantity of nationally owned separated plutonium is expected to reach 140 teHM.

The UK Government views the development of a suitable disposition strategy for this material as a high priority, partly due to the annual cost of £80 million ($115 million) for safe storage of the material. The plutonium has a highly variable isotopic composition throughout the inventory due to it having been produced from a number of reactor types with different power and burnup histories. The material has aged in storage for up to 60 years, during which time decay products have built up, such as americium-241.

The UK National Nuclear Laboratory (NNL) has the task of assessing options for plutonium disposition. They are considering four main options [1]:

- –

immobilisation in a suitable engineered waste form, followed by disposal in a mined deep geological repository;

- –

production of MOX fuel for use in a suitable light water reactor (LWR) such as the AREVA EPR, General Electric-Hitachi Nuclear Energy ABWR, Westinghouse AP1000 or China General Nuclear Power Company Ltd./China National Nuclear Corporation HPR1000;

- –

production of a MOX fuel, with a lower plutonium fraction than LWR MOX fuel, suitable for use in a PHWR such as the Atomic Energy of Canada Ltd. (AECL) EC-6;

- –

production of a metallic alloy fuel of plutonium, zirconium and uranium suitable for use in the GE-Hitachi PRISM, a liquid sodium-cooled fast reactor.

The disposal option focuses on the disposal of all or the majority of the total plutonium inventory. It is expected that even if one or more reuse options are selected, there will remain a requirement to dispose of at least some amount of lower quality material directly. However, analyses carried out by CANDU Energy have shown that all UK plutonium is suitable for either direct use in the EC-6 reactor, or can be blended with other plutonium stocks in the inventory to be made suitable for reactor use [2].

As of early 2014, the preferred option of the UK Department of Energy & Climate Change (DECC) for plutonium disposition was reuse in a MOX fuel in LWRs scheduled to be built in the UK in the next 10–15 years. Previous attempts to produce MOX fuel in the UK have had limited success. The Sellafield facility designed for the fabrication of MOX operated from 2002–2011 with a design capacity of 120 te/year, reduced to 72 te/year during commissioning. However, during its first five years of operation, the plant produced only 5.2 te of MOX fuel [3], and produced less than 15 te over its life to 2010. It has also been calculated that the true cost of design, construction and operation of any replacement MOX plant would be higher than the value of all fuel produced by the plant [4].

The UK Nuclear Decommissioning Authority and NNL have accepted alternative proposals from other agencies, and three have been put forward. AREVA has proposed the construction of a MOX fabrication plant capable of producing mixed oxide (MOX) fuels for use in LWRs, although currently there are no requirements for plant operators to irradiate the resulting MOX fuel. The proposal from GE-Hitachi Nuclear Energy considers the use of the PRISM reactor, and the NDA have indicated “no fundamental impediments” to the licensing of this reactor, but are yet to declare the proposal to be credible [1]. The AREVA and GE-Hitachi proposals have a number of merits, but these proposals will not be discussed further in this paper. Instead, the focus will be on the proposal from AECL, UK CANMOX. The UK CANMOX proposal suggests the irradiation of the plutonium inventory as part of a MOX fuel with depleted uranium tails in a PHWR, the EC-6 reactor. It is a complete fuel cycle proposal, including the construction and operation of a fuel fabrication facility and sufficient reactors to irradiate the resulting fuel, as well as consideration given to spent fuel management.

The AECL proposal suggests the use of two MOX fuels containing approximately 2.5 and 5% plutonium mixed homogeneously with a depleted uranium host. These fuel blends would be fabricated into 43-element “CANFLEX” fuel bundles, and would be irradiated to 20,000 MWd/te within EC-6 reactors. Thirty-five of the 43 fuel elements would contain the MOX fuel, with the other eight containing dysprosium oxide (Dy2O3) in depleted uranium oxide. Dy2O3 is a burnable neutron absorber, used for radial flux flattening across the bundle. The dysprosium loading fraction in the fuel elements is unknown. Each reactor would consume approximately 1.3 tePu/yr from the inventory, requiring four units running over a 30-year lifetime to consume the UK stockpile [5]. The EC-6 reactor has an operational design lifetime of 60 years, with a mid-life shut down period for refurbishment of key reactor components, notably the pressure tubes which hold the fuel bundles and carry the pressurised heavy water coolant. It is anticipated that following this mid-life refurbishment the reactor would then be operated for the second 30 years of its life with a uranic fuel. The NDA have declared the proposal to be a “credible” option [1].

The spent fuel from UK CANMOX does still contain significant quantities of plutonium. However, in-core irradiation will alter the isotopic ratio to reduce the fissile quality of the material. A burnup of approximately 20,000 MWd/te has been proposed for UK CANMOX fuel, compared to the approximately 7000 MWd/te burnup of natural uranium fuelled CANDU reactors, and this will induce a significant isotopic conversion of the plutonium. The spent fuel would not be reprocessed prior to disposal, maximising the proliferation resistance of the material. Spent fuel quantities from heavy water reactors are generally much greater than those from LWRs for the same power output due to the lower burnups achieved. A given quantity of heavy water reactor natural uranium spent fuel may be emplaced into a smaller volume in a geological repository as the fuel is also less heat generating [2]. However, this may not be the case for MOX fuels containing significant quantities of plutonium.

As well as the plutonium inventory built up from reprocessing activities, the UK also holds an inventory of uranic materials, including depleted uranium tails from enrichment activities, MAGNOX depleted uranium (MDU) from reprocessing of MAGNOX reactor fuels, and ThORP product uranium (TPU) from reprocessing uranium oxide fuels from advanced gas-cooled reactors (AGR). EDF Energy, the operator of the AGR fleet, also owns a significant quantity of TPU. The inventory is detailed in Table 1 [6,7]. If these inventories were to be used in nuclear fuels the result would be to reduce the overall quantity of natural uranium required per kilowatt-hour of electricity generated in the UK.

The EC-6 is described as fuel flexible, and AECL have proposed multiple alternative fuelling regimes suitable for the reactor, including plutonium-thorium MOX fuels and reprocessed uranium fuels [8]. There is ongoing work into the development of natural uranium equivalent (NUE) fuels which blend depleted and reprocessed uranium stocks to produce a synthetic uranium oxide fuel with similar properties to natural uranium [9].

The work described here details initial studies into alternative two- and three-component nuclear fuel concepts for the EC-6 reactor. Neutronic feasibility studies and nuclear fuel materials availability assessments have been performed into the use of U-Pu and U-Pu-Th nuclear fuels in the EC-6 PHWR. Six uranium sources were considered: depleted uranium tails, natural uranium, reprocessed uranium from an EPR fuelled with enriched uranium, reprocessed uranium from an EPR fuelled with U-Pu MOX, MDU and TPU. Three plutonium sources were considered: an average plutonium composition from the UK inventory, reprocessed plutonium from an EPR fuelled with enriched uranium and reprocessed plutonium from an EPR fuelled with U-Pu MOX. The isotopic compositions of these uranium and plutonium sources are listed in Table 2 [10,11] and Table 3 [11,12]. Only natural thorium was considered, being 100% Th-232.

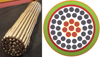

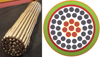

The concept fuels developed for this study were based on the CANFLEX 43-element fuel bundle, shown in Figure 1. While these concepts include two-component MOX fuels based on uranium and plutonium, the larger focus is on three-component fuels which also include thorium. Thorium is fertile, whilst uranium and plutonium can be both fertile and fissile. In the proposed concepts thorium oxide fuel elements would replace the burnable neutron absorber elements from the UK CANMOX proposal. As a fertile material thorium can become fissile through the neutron capture process, producing additional useable fuel material, uranium-233, after undergoing radioactive decay through protactinium-233, which has a half-life of 27 days. Neutron capture on Pa-233 may lead to the production of U-232, a problematic, non-fissile nuclide, and is to be avoided. Thorium is currently produced as an impure by-product of the rare earth mining and purification process from monazite ore, but is largely disposed of as a hazardous waste material despite potential reactor fuel applications.

CANFLEX bundles include three different fuel element types arranged in three concentric rings surrounding a central element [13]. The central element and inner ring of seven elements have a diameter of 13.5 mm, and contain fuel pellets composed of a dysprosium oxide burnable neutron absorber in depleted uranium oxide. The 14 elements in the intermediate ring and 21 elements in the outer ring have a diameter of 11.5 mm. In UK CANMOX fuel, the outer ring contains approximately 2.5% Pu in depleted uranium, while the intermediate ring contains approximately 5% Pu in depleted uranium. Such a design gives improved flux flattening across the bundle with more effective heat transfer to the coolant when compared to the currently used 37-element bundle, which uses in a single fuel element diameter [14]. Bundles are ∼500 mm long and 100 mm in diameter. The EC-6 core has 380 horizontal fuel channels, each of which holds 12 bundles [15].

The proposed three-component fuel concepts use a heterogeneous fuel bundle, with thorium oxide in the eight large-diameter inner fuel elements and a uranium-plutonium MOX in the 35 small-diameter outer fuel elements. Doing so means the thorium and U-Pu MOX are physically and chemically separated, and so minimises fuel cycle back end processing difficulties associated with the three-component fuel. Any back end process may begin with an automated disassembly of the bundles, allowing separate treatment of U-Pu MOX and thorium oxide spent fuel elements.

The thorium replaces the burnable absorber in the central eight fuel elements of the UK CANMOX proposal. As the thermal neutron flux in the centre of the bundle is low due to the shielding provided by the MOX elements, the capture of neutrons by Pa-233 is reduced and should allow for a higher conversion of thorium to fissile U-233. This separation of the fissile and fertile fuel regions is in-line with other thorium CANFLEX concepts [16]. It is anticipated that the neutronic coupling of thorium and plutonium will produce some mutual self-shielding effects. Neutron capture on both Th-232 and Pa-233 will be reduced due to captures on Pu-240 and Am-241 present in the plutonium. Such capture reactions will also reduce the fission of Pu-239.

|

Fig. 1 Left: photograph of 43-fuel element CANFLEX fuel bundles; right: diagram showing CANFLEX fuel elements in pressure tube (red) with annular gas space (green) contained within calandria tube (orange). |

2 Neutronic analysis of fuel concepts

An empirical calculation method was developed to perform calculations on the neutronic feasibility of the various fuel combinations. A total of 36 fuel bundle composition concepts were suggested, each with differing plutonium:uranium ratios. Of these, 20 were subsequently evaluated, as preliminary analyses indicated that reprocessed uranium from LWR MOX fuels would perform less well than depleted uranium tails whilst being more problematic to fabricate due to its U-234 and U-236 content, and that the use of natural uranium would not bring any of the desired sustainability advantages to the fuel concept. Only one fuel based on AGR reprocessed uranium was considered during the early stages of the work due to the limited availability of the material, although this was developed further in later stages.

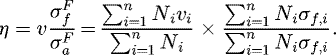

The common fuel for CANDU reactors is natural uranium oxide. All fuel concepts studied in this work are compared to natural uranium as the reference fuel. The screening was performed by comparing the fuel reproduction factor η, also known as the neutron yield factor, and fission:capture ratio α−1, of each fuel concept to the reference fuel. The formula for reproduction factor, the number of fast neutrons produced per thermal neutron capture in the fuel, is given in equation (1), where ν is the average number of neutrons produced per fission in the fuel, σF is the microscopic neutron cross section for fission or absorption in the fuel as denoted by the subscript f or a respectively, Σ is the sum operator, n is the total number of fuel isotopes, i is a number representing each fuel isotope, and N is the number density of the isotope in the fuel bundle. (1)

(1)

The fission:capture ratio, the overall ratio of microscopic fission capture cross section to microscopic capture cross section, is calculated using equation (2). (2)

(2)

The calculation method used for the initial screening study does not account for the neutronic contributions of structural materials or the heavy water moderator and coolant. Only fuel isotopes are considered. The results of the calculations therefore do not give an absolute value for the whole core multiplication factor or absolute fission:capture ratio. Instead results for the reproduction factor are presented as comparisons against the reference natural uranium fuel, as well as a number of operating and proposed fuel compositions calculated under the same method. Structural materials and moderator are present equally in all fuel concepts and have little effect on reproduction factor. The fuel cladding and structural materials are largely zirconium alloys, and the moderator and coolant are heavy water. These materials have a low capture cross section relative to fuel materials, and so neutronic contributions from non-fuel materials may be ignored when using this comparative approach. This was demonstrated and is shown below in Section 3. All calculations are for fresh, unirradiated fuel.

The number densities of the atoms of each isotope were calculated as follows. The total mass of each isotope of uranium, plutonium and thorium present in the concept fuel bundle was calculated from the geometry of the fuel pellet stacks [9], density [17] and isotopic composition data. Pellets were assumed to be uniform cylinders, although real pellets have chamfered edges and dished end faces, meaning that the total mass of fuel is slightly overestimated. The total volume of the outer and intermediate ring fuel pellets was calculated to be 1500 cm3, while the total volume of the inner ring and central fuel element pellets was calculated to be 478.4 cm3, based on the diameter of the pellets and the pellet stack length. The total masses of the two fuel pellet sets were then calculated based on the plutonium loading fraction and the theoretical densities of UO2, PuO2 and ThO2, using an assumption of 95% of the theoretical material density in the pellets. The masses of elemental thorium, uranium, plutonium and other elements were then calculated, and the isotopic compositions in Tables 2 and 3 used to calculate the mass of each fuel isotope in the bundle.

For this screening study, it was assumed that the fuel isotopes were homogeneously distributed through the volume of the fuel bundle. The masses of each isotope were used to calculate the atomic density of each isotope across the fuel bundle total volume of 3927 cm3. Although the homogeneity assumption has a significant effect on the validity of the calculation, the results are presented only in relative terms, and should not be used to infer absolute performance of the fuel concepts. Thermal neutron interaction data at 300 K from the JENDL-4.0 data library [18] were used with the atomic densities to analytically calculate the macroscopic cross sections for fission, capture and scattering, and the reproduction factor η and fission:capture ratio α−1 were evaluated. Only thermal neutron interactions were considered, fast neutron interactions were not included in screening the concepts. The lack of fast neutron induced fission in the calculation meant that the core initial reactivity would be underestimated.

3 Neutronic analysis results

Table 4 shows the results from the neutronic feasibility assessment for the concept fuels proposed, alongside results for a variety of more developed fuels studied under the same method for comparison and validation. One fuel in particular, comprising 2.5% UK inventory plutonium in depleted uranium, was selected to represent a mimic for UK CANMOX fuel. While this fraction is below the actual average plutonium loading of the fuel, it also does not account for dysprosium as the fraction is unknown. Detailed development of UK CANMOX fuel is given below in Figure 2 and the associated text.

The results shown are normalised to the results for natural uranium. Values greater than unity for the normalised reproduction factor and fission:capture ratio are taken to indicate neutronic feasibility for the fresh unirradiated fuel. Fuel concepts 1–9 are two-component MOX fuels. Fuel concepts 10–18 use the same MOX compositions as fuels 1–9 respectively, but are three-component fuels with a thorium core region. The effect of the addition of the thorium region can be seen by comparing the three-component fuel of interest to the equivalent MOX two-component fuel. Fuels 19 and 20 are additional fuel concepts using additional uranic materials.

Two-component MOX nuclear fuels based on depleted uranium are seen to require a minimum loading of ∼2–3 wt% Pu to be comparable with natural uranium. Reprocessed uranium from MAGNOX reactors only provides a minor neutronic advantage when compared to uranium enrichment tails. In practice, this advantage may not outweigh the difficulties introduced to fuel fabrication when working with irradiated uranium. The UO2-fuelled EPR reprocessed uranium gives a significant neutronic benefit, allowing lower plutonium fractions when compared to other fuels, thus maximising the energy value of the plutonium – the quantity of electrical energy produced per unit mass of inventory plutonium irradiated in the core. However, studies into the effect of burnup would be required to confirm this.

The three-component fuels 10–18 suffer significant neutronic penalties due to the replacement of fissile MOX by thorium when compared with their equivalent two-component MOX fuels, and necessitate increased plutonium loading to offset the use of the fertile material. At 1% plutonium loading only fuels 16, 17 and 19 have normalised neutronic values equal to or greater than unity, suggesting the requirement for slightly enriched uranium. In addition, higher plutonium fractions allow the use of lower quality fissile uranium resources.

Some three-component fuels may be comparable with the UK CANMOX mimic fuel. Concept fuels 16, 17, 19 and 20 have similar calculated neutronic parameters to 2.5% plutonium loaded within a depleted uranium host, although approximately 5% Pu would be required in the concept fuels to match the calculated reproduction factor and fission:capture ratio of the UK CANMOX mimic.

The calculation method used here does not allow for accurate calculation of achievable fuel burnup in the reactor, as the reproduction factor is only a measure of instantaneous reactivity, which does not account for differences in the slope of reactivity depletion caused by fuel composition changes. As such, it was not possible to study whether the comparatively high levels of burnup desired in the UK CANMOX proposal are actually achievable with the proposed fuel concepts using the calculation tools available. Some estimates are provided for proposed fuel concepts based on the assumption of equivalent reactivity depletion over time. However, these are only intended to inform as to a possible starting point for further detailed calculation beyond the scope of this screening study.

Fuels 17 and 19 are of interest for further study. Fuel 19 should be developed further as an option for the irradiation of the UK plutonium inventory in the EC-6 reactor, as it can allow the reuse of reprocessed uranium stocks from AGR reactors. Fuel 17 should be developed as an alternative option to LWR MOX in the UK; reprocessing of LWR spent fuel produces a product that appears to be suitable for refabrication into a three-component nuclear fuel for irradiation in EC-6 reactors. Fuel 16 is potentially less interesting as it requires reprocessing of EPR spent fuel without considering the future of the plutonium produced, and fuel 20 is less interesting as it uses natural uranium, and a secondary aim of this work was to reduce the requirement for fresh natural uranium.

The neutron reproduction factor and fission:capture ratio do not give a complete representation of homogeneous reactor neutronic multiplicity. In order to determine the impact of other reactor structural materials and the moderator on the neutronic performance, a more in-depth calculation has been performed on some selected fuels. UK CANMOX fuel with a range of burnable absorber loadings and fuel concepts 17 and 19 with a range of plutonium loadings were studied in greater detail, with natural uranium in a 37-element CANDU bundle used as a reference. The reproduction factor is one of the terms of the six-factor formula for neutron multiplicity in a finite homogeneous reactor, given in equation (3), where keff is the effective multiplicity factor, η is the reproduction factor, p is the resonance escape probability, ε is the fast fission factor, PFNL is the fast non-leakage probability and PTNL is the thermal non-leakage probability. (3)

(3)

Data on reactor and fuel geometry and materials taken from work by Türkmen and Zabunoğlu [13] has been used to estimate the total mass of heavy water moderator and coolant, structural zircaloy-4, fuel and carbon dioxide insulating gas in the core, as presented in Table 5. The structural materials considered are the pressure and calandria tubes, fuel cladding and fuel bundle structures, but not the calandria tank vessel or components associated with core control such as control rods or dissolved boron in the moderator.

Thermal spectrum neutron cross sections and resonance capture integrals from the JENL-4.0 library [18] were used to determine values for the thermal utilisation factor f, resonance escape probability p, thermal non-leakage probability PTNL and fast non-leakage probability PFNL. The fast fission factor was set to unity. The neutron multiplicity factor keff was then evaluated using these factors and the reproduction factor as previously calculated. For a typical thermal reactor, the fast fission factor is slightly greater than unity, and as such it is expected that keff is slightly underpredicted by this method.

Calculations of keff, p, f, η, PFNL and PTNL were carried out for a natural uranium fuel in a standard 37-element CANDU fuel bundle. The results for the natural uranium fuel are shown in Table 6.

The value of 1.131 for the effective multiplicity factor seems an appropriate initial value for a reactor with relatively low final burnup such as a CANDU reactor with natural uranium fuel.

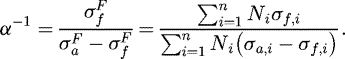

Results of the final neutronic factors for CANMOX fuel and fuel concepts 17 and 19 are presented in Figures 2, 3 and 4. Only those factors which vary as a function of the plutonium or dysprosium loading are presented. In all cases the fast non-leakage probability was found to be very close to unity, the thermal non-leakage probability was found to be 0.99, and the fast fission factor was assumed to be 1.00.

It can be seen in Figure 2 that the UK CANMOX fuel has an initial keff that is heavily dependent upon the level of loaded burnable absorber. With no initial dysprosium keff may be up to 1.48 under the previously discussed assumptions, falling to a value of 1.00 with 3.84% Dy loading. An equivalent initial multiplicity factor to natural uranium fuel in a 37-element fuel bundle may be achieved with 2.46% Dy. The actual fraction of Dy loading is unknown, but it may be assumed that the actual loading is unlikely to be significantly greater than 4% by mass in the eight central fuel elements.

The proposed three-component fuel concepts have a highly variable keff which reaches a maximum value at approximately 8.8% plutonium loading, although it remains within 90% of this maximum value over the range of 2–30% plutonium loading. Below approximately 4%Pu, the reproduction factor reduces rapidly as the Pu fraction tends to zero. At high Pu% additional plutonium has little impact on the reproduction factor, but resonance absorption has an increasing negative impact on the keff.

The calculation of neutronic factors here is only for a complete core of unirradiated fuel. It is anticipated that in operation, depleted uranium fuel bundles will be placed through the core to balance the initial reactivity excess and power profile. This will be used in conjunction with boron chemical shim control [2].

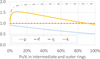

Calculated relative reproduction factors and fission:capture ratios for two and three-component mixed oxide (MOX) concepts with 1, 2 and 3% by mass plutonium loading in MOX fuel elements.

|

Fig. 2 Evaluated values of neutronic factors as affected by dysprosium burnable absorber loading in UK CANMOX fuel. |

Mass of material in homogeneous core.

|

Fig. 3 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 17, comprising a mixed oxide fuel of UO2-fuelled EPR reprocessed uranium and plutonium in the seed region and natural thorium oxide in the blanket region of the CANFLEX fuel bundle. |

|

Fig. 4 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 19, comprising a mixed oxide fuel of UK inventory plutonium and ThORP product uranium in the seed region and natural thorium oxide in the blanket region of the CANFLEX fuel bundle. |

4 Nuclear materials availability for fuel concepts

In addition to neutronic feasibility, calculations were undertaken to determine whether there would be sufficient nuclear material to fuel the EC-6 plant over the 30-year MOX operational period. Thirty years was selected as the operational time period in order to be in-line with the proposed timescale for UK CANMOX, although the design operating lifetime for the EC-6 reactor is 60 years. For fuels based on EPR reprocessed materials, a LWR:EC-6 support ratio has been determined, based on the lifetime spent fuel produced from an EPR and the EC-6 fuel requirements. The LWR:EC-6 calculations are for fuel production/use in equilibrium, and do not take account of the transient availability of spent nuclear fuel from LWRs. For fuels based on UK inventory materials, calculations have been undertaken to determine the number of EC-6 reactors required to consume the UK inventory over the course of the 30-year period, whilst ensuring the availability of sufficient uranium to produce the desired MOX component of the fuel.

When producing fuels based on spent fuel and inventory material, the availability of material in sufficient quantity must be determined. The annual fuel requirement for an EC-6 is calculated using equation (4), where P is the reactor electrical power in megawatts, C is the reactor capacity factor, ε is the reactor thermal efficiency and BU is the fuel discharge burnup in megawatt days per tonne [14]. (4)

(4)

Assuming equivalent reactivity depletion with natural uranium, for a fuel with similar neutronic parameters to natural uranium with 1% Pu and 7000 MWd/te burnup, 112,100 kg/yr of fuel will be required. For a fuel similar to the proposed UK CANMOX fuel with 5% Pu and 20,000 MWd/te burnup, assuming equivalent reactivity depletion, 39,200 kg/yr of fuel will be required. These values convert to requirements of 6300 and 2200 fuel bundles per reactor.year, respectively. For a three-component fuel loaded with 1 or 5% plutonium in the MOX fuel, the annual and 30-year fuel requirements are displayed in Table 7.

If the assumption is made that matching the neutronic parameters to the more well studied fuels will allow similar discharge burnups to be achieved, the results above indicate that approximately 104 te of separated UK plutonium could be irradiated to 7000 MWd/te with four EC-6 reactors burning the proposed three-component fuels with 1% Pu MOX over a 30-year period. Similarly, 91 te of the inventory could be irradiated to 20,000 MWd/te if 5% plutonium loading were used in three EC-6 reactors over 30 years. However, further work will be required to determine a reliable relationship between fuel burnup and reactivity.

With regard to uranium resources, using a 1% plutonium loading with four reactors, a total of 10,300 te of uranium would be required. For the 5% Pu, 20,000 MWd/te scenario with three reactors, 2600 te of uranium would be required. The data provided in Table 1 indicate the availability of approximately 5600 te of TPU. Thus, it would be possible to operate three EC-6 reactors using fuel concept 19 in high burnup mode, consuming 137 te of UK inventory Pu and 2600 te of existing TPU. However, there is insufficient TPU to operate fuel concept 19 in the low burnup mode.

Using a blend of the available 5600 te of TPU and 4700 te of MDU, a sufficient uranium stock to operate fuel concept 19 in low burnup mode could be created. This blended uranium would have 0.62% U-235. The six-factor formula neutronic parameters which vary with plutonium fraction are shown in Figure 5. It can be seen that the use of the blended uranium has a minimal impact on the multiplicity factor.

If three-component fuels were to be fabricated from EPR spent fuel as in the case of fuel concept 17, an EPR:EC-6 support ratio must be calculated. The various options for fuel plutonium fraction, composition, burnup, and the number of reactors of each type define a large envelope within which any real support ratio will be found. However, some possible scenarios with associated ratios are defined here.

In the low burnup mode, a 0.3% Pu loading is required for the calculated multiplicity factor to be greater than that of natural uranium. Such a low plutonium fraction would mean that only 7.8 te of plutonium would be consumed in each EC-6 over 30 years, and 2600 te of uranium would be required to support this.

In high burnup mode, 5.7% Pu loading is required for the calculated multiplicity factor to be greater than that of the mimic CANMOX fuel, giving a Pu requirement of 52 te and U requirement of 860 te per EC-6 reactor over a 30-year period.

An EPR fuelled by 5% enriched UO2 over its life will produce 3400 spent fuel assemblies [19], giving a lifetime spent fuel production of 22.5 te Pu and 1650 te U [11]. Thus, in low burnup mode, the support ratio might be 3 EC-6 reactors per 2 EPR reactors, selected on the basis on plutonium management, requiring a makeup of 250 te of inventory uranium and producing an excess of 0.9 te of plutonium over the 30 years. In high burnup mode, the ratio might be 2.3 EPR reactors per EC-6 reactor, which would use all produced plutonium but produce an excess of 3000 te uranium. Alternatively, two EC-6 reactors might be operated per EPR, consuming all produced uranium but producing a 30-year excess of over 80 te of plutonium.

In the case of excess uranium production, referring back to Table 2, it can be seen that EPR reprocessed uranium is the most enriched in U-235 of all the uranium sources, and this material might be blended with some quantity of uranium enrichment tails to produce a NUE fuel [8]. Excess plutonium is not acceptable, as it goes against the key reason for implementing EC-6 reactors in the first place.

Annual and 30-year fuel materials requirements per enhanced CANDU-6 with proposed three-component fuel.

|

Fig. 5 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 19 with blended uranium produced from 5600 te TPU and 4700 te MDU. |

5 Fuel cycle integration

Four three-component fuel concepts are suggested for further development for future deployment in the United Kingdom. The first pair use materials from the UK inventory, the second pair are for irradiation of MOX fuels produced from reprocessing of spent fuel produced by the planned UK EPR reactors. Four EPRs are currently planned for the UK, thus calculations have been performed to determine the reactor support ratio and whether there will be a surplus or net deficit of nuclear material to run an EC-6.

It can be seen that the lower burnup options, while not irradiating the plutonium as strongly, gives a better energy value for the plutonium by allowing the operation of a larger number of reactors. However, it should be borne in mind that the quantity of spent fuel produced by an EC-6 reactor in low burnup mode will be approximately three times greater than for an EC-6 in high burnup mode. Also the spent fuel from a low burnup reactor will retain a higher fissile plutonium fraction when compared to a high burnup fuel. The radiation field from a low burnup fuel would be expected to be lower, potentially facilitating fuel cycle back end operations, although the field strength would still prevent anything less than hot cell processing.

The high burnup, high plutonium fuel produced from the UK nuclear materials inventory might be composed of 7.5% inventory plutonium in TPU. Over 30 years, two EC-6 reactors could irradiate 137 te Pu and 1690 te TPU to 20,000 MWd/te, operating under the previous key assumption of equivalent reactivity depletion compared to the reference fuels.

The low burnup, low plutonium fuel produced from the UK inventory might be composed of 1.3% plutonium in TPU. Over 30 years, 135 te Pu, 5600 te TPU and 4700 te MDU would be irradiated to 7000 MWd/te in four reactors.

The high burnup, high plutonium fuel produced from reprocessing UK EPR spent fuel might be composed of 5.7% EPR plutonium in EPR reprocessed uranium. One EC-6 in this configuration could consume the plutonium of 2.3 EPRs over 30 years. With the addition of a supplementary 118 te of inventory Pu, the spent fuel from the four planned UK EPRs will be sufficient to operate four EC-6 reactors at high burnup over the course of 30 years. The EC-6 reactors would not be able to consume all EPR reprocessed uranium, and the lifetime net production of reprocessed uranium would be 3150 te.

The low burnup, low plutonium fuel produced from reprocessed UK EPR spent fuel would be composed of 1.35% EPR plutonium in EPR reprocessed uranium. One EC-6 can consume the plutonium and uranium produced from 1.56 EPRs. Four EPRs will provide enough plutonium and uranium to supply six EC-6 reactors if supplemented by 121 te of inventory plutonium, 5600 te of TPU and 3240 te of MDU over the course of 30 years.

The use of reprocessed EPR spent fuel materials in the three-component fuel would mean that it would not be possible to dispose of all inventory plutonium within the 30-year time frame proposed by UK CANMOX to DECC. This may be resolved by only reprocessing a proportion of the EPR spent fuel, or by taking the decision to reprocess and make use of all EPR spent fuel over the full 60 years of the EC-6 life. In either case no MOX fuel would be able to be irradiated in the EC-6 until the first EPR fuel had been reprocessed, giving a year for first three-component MOX irradiations of at least 2030. The time scale for fabrication of a MOX fuel from inventory materials only is shorter, being governed by the time taken to bring a fuel fabrication facility to operational status.

6 Conclusions and future work

Three-component U-Pu-Th fuels have been studied using a simplified model giving early indications of their potential feasibility for use in the EC-6 reactor using the CANFLEX 43-element fuel bundle. Although the method is based on significant assumptions, results can be considered as at least indicative, as they are presented as relative to other fuels which have been studied in more detail, specifically the currently used natural uranium fuel, a mimic for the proposed UK CANMOX fuel [5], low Pu-DU MOX fuels [12] and Pu-Th fuels [20].

Two possible operation modes have been suggested, low and high burnups. The low burnup mode uses fuels calculated to have similar neutronic parameters to natural uranium fuel in the EC-6 reactor. The high burnup mode uses fuels calculated to have similar neutronic parameters to a 2.5% Pu MOX fuel selected to mimic the UK CANMOX fuel suggested by AECL for UK plutonium inventory disposition.

Calculations indicate that there are several feasible fuel concepts. Based on these, a recommendation is made to further develop fuel cycle options for a three-component fuel in the EC-6 reactor.

The first concept uses only UK inventory nuclear materials. Depending on the desired level of burnup in the final fuel, it may be decided to adopt either of the inventory materials concepts described in this work. The low burnup fuel concept does not irradiate the fuel as heavily, and will give a larger overall EC-6 spent fuel inventory, converting materials which are currently a low risk for disposal such as reprocessed uranium into higher risk spent fuel.

The second fuel concept encourages blending of current uranic inventory materials with new reprocessed spent fuel materials from LWRs, specifically the AREVA EPR. The UK is moving away from nuclear fuel reprocessing, but if reprocessing were to restart it has been shown that these fuel concepts will allow the treatment of the plutonium and uranium products. The deployment of appropriate fuel cycle facilities and LWRs strongly determines the feasibility of such concepts.

The use of three-component fuels adds significantly to the complexity of fuel cycle operations, but the potential advantages are significant and may outweigh the drawbacks related to this increased complexity.

Heavy water reactors have a number of disadvantages when compared to LWRs, including the greater production of spent fuel, the cost of heavy water and the possibility of licensing difficulties due to their positive void coefficient [21]. However, the EC-6, at low plutonium loading levels, produces a large quantity of energy per unit of plutonium fuel and is a complete proposal for plutonium disposition based on generally very mature technologies. UK CANMOX will be a strong option for NNL when selecting an option for UK plutonium disposition if energy value is an important criterion. Three-component fuels can provide benefits over the proposed UK CANMOX fuel in terms of nuclear materials inventory utilisation, and the use of a thorium region in the fuel may be beneficial in terms of extending fuel lifetimes in the core as the thorium is converted to fissile uranium-233.

Of the various fuelling options discussed in this paper, it is the authors’ recommendation at this stage that the high burnup fuels be preferred. The rapid disposition of inventory plutonium should be prioritised, and high burnup operation using inventory materials only for the first 30 years of the EC-6 operation cycle will be effective in achieving this. For the second 30 years of operation, MOX fuels based on LWR reprocessing products might be developed as an alternative to operation with natural uranium or natural equivalent fuel based on inventory uranic materials, for example a TPU/MDU blend.

A significant amount of development work remains to be carried out before the most promising three-component fuel options from this screening study may be considered as a feasible option for use in a reactor core. The neutronic behaviour of the various fuel components with one another and the other materials within the core must be studied. In particular it is anticipated that the use of multiple fuel materials together may produce complex neutronic interactions that cannot be easily predicted. Heterogeneous features of the fuel bundle and core will also have significant impacts which this study cannot foresee.

The irradiation history impacts on the fuel must be established with various levels of burnup, as well as the impact of burnup on reactivity. The EC-6 reactor is refuelled continuously at power, with several refuelling operations carried out per week according to the power profile and actual burnup in the core. It will be necessary to determine if and how a core composed of many three-component fuel bundles may be operated. Linear fuel element power ratings are expected to be a strong limiting factor in determining the plutonium loading limits, and thorium conversion may also drive increases in the element power. The neutronic parameters calculated in this work must be validated by a robust neutronics calculation technique. For these purposes a Monte Carlo neutronics simulation is suggested, either using a stochastic modelling code or a deterministic code suitable for PHWRs such as WIMS-AECL [22] and RFSP [23] or a combination of DRAGON [24] and DONJON [25].

Additional studies would also need to consider fuel cycle options for such fuels – how they may be manufactured and handled before irradiation and how operators might deal with spent fuel bundles according to their heat generation and radiation field. Dynamic analyses of strategies for how such fuels might fit into the existing nuclear energy systems of the United Kingdom are suggested.

In summary, this work has suggested that there may be feasible EC-6 reactor fuel compositions based on reprocessed plutonium and uranium MOX fissile drivers operating alongside thorium oxide fertile regions within a CANFLEX fuel bundle. The quantity of suitable plutonium and uranic materials to produce these fuels appears to be available in the United Kingdom. However, this work represents a mere first step in the exploration of these fuel options, and further work is required before such fuels might be deemed to be feasible.

Acknowledgments

The primary author would like to thank AREVA for providing data and support during the course of this work, which was largely carried out during the course of an internship with the company.

Thanks also go to the UK Engineering and Physical Sciences Research Council, the Nuclear FiRST Doctoral Training Centre and ERASMUS+ who provided funding for this work.

Nomenclature

ABWR: advanced boiling water reactor

AECL: Atomic Energy of Canada Ltd.

AGR: advanced gas-cooled reactor

AP1000: advanced passive 1000 (reactor)

CANDU: Canadian deuterium uranium (reactor)

DECC: Department of Energy & Climate Change

EC-6: enhanced CANDU-6 (reactor)

EPR: European pressurised reactor – or – evolutionary power reactor

HPR1000: reactor design formally known as “Hualong One”.

IAEA: International Atomic Energy Agency

MAGNOX: magnesium non-oxidising. Refers to a UK reactor design which used this material as a fuel cladding

NDA: Nuclear Decommissioning Authority

NNL: National Nuclear Laboratory

PHWR: pressurised heavy water reactor

PRISM: power reactor – inherently safe module

ThORP: thermal oxide reprocessing plant

References

- UK Nuclear Decommissioning Authority Report No. SMS/TS/B1-PLUT/002/A, 2014, http://www.nda.gov.uk/publication/progress-on-approaches-to-the-management-of-separated-plutonium-position-paper/ [Google Scholar]

- P.J. Reid, in Proceedings of the CANDU Energy Academic Information Series, University of Manchester, 18–19 March, 2015 (unpublished) (2015) [Google Scholar]

- UK House of Commons, M. Wicks, UK Parliament Report No. HC Deb 22 Feb 2008, Vol. 472, Column 1032W, 2008, http://www.publications.parliament.uk/ [Google Scholar]

- UK Committee of Public Accounts, UK Parliament Report No. HC 708, 2014, http://www.publications.parliament.uk/ [Google Scholar]

- A. Simper, Plutonium management (Cambridge Nuclear Energy Centre, Cambridge, 2014), http://www.cnec.group.cam.ac.uk/ [Google Scholar]

- UK Nuclear Decommissioning Authority, 2013, http://www.nda.gov.uk/ [Google Scholar]

- UK Nuclear Decommissioning Authority Report No. Technical Note 16518861, 2012, http://www.nda.gov.uk/ [Google Scholar]

- S. Azeez, J. Hopwood, in Proceedings of the International Conference on Opportunities and Challenges for Water Cooled Reactors in the 21st Century, Vienna, Austria (2009), http://www-pub.iaea.org/ [Google Scholar]

- V. Aleyaseen, C.M. Cottrell, S. Kuran, Demonstration of a new recycled fuel for CANDU, 2014, http://www.neimagazine.com/ [Google Scholar]

- D.R. Parker, R.W. Mills, British Nuclear Fuels Ltd. Report No. RAT 1972, 2001, http://www.oecd-nea.org/ [Google Scholar]

- B. Carlier, J.Y. Doriath, J.P. Grouiller, P. Tetart (unpublished) [Google Scholar]

- J. Lonchampt (unpublished) [Google Scholar]

- M. Türkmen, O.H. Zabunoğlu, J. Nucl. Mater. 429, 263 (2012) [CrossRef] [Google Scholar]

- W.W.R. Inch, J.H. Lau, P.D. Thompson, P.J. Reid, in Proceedings of the COG/IAEA 6th Technical Committee Meeting on the Exchange of Operational Safety Experience of Pressurised Heavy Water Reactors, Trois Rivières, Quebec (2000) [Google Scholar]

- CANDU Energy Inc., Enhanced CANDU-6 Technical Summary, 2012, http://www.candu.com/ [Google Scholar]

- P.G. Boczar, B. Hyland, K. Bradley, S. Kuran, in Proceedings of the 18th International Conference on Nuclear Engineering 2010, New York (American Society of Mechanical Engineers, 2011), Vol. 6 [Google Scholar]

- S.G. Popov, J.J. Carbajo, V.K. Ivanov, G.L. Yoder, Oak Ridge National Laboratory Report No. ORNL/TM-2000/351, 2000, http://web.ornl.gov/ [Google Scholar]

- K. Shibata, O. Iwamoto, T. Nakagawa, N. Iwamoto, A. Ichihara, S. Kunieda, S. Chiba, K. Furutaka, N. Otuka, T. Ohasawa, T. Murata, H. Matsunobu, A. Zukeran, S. Kamada, J.-I. Katakura, J. Nucl. Sci. Technol. 48, 1 (2011) [Google Scholar]

- S. Greenwood, G. Craig, S. Rosenberger, C. Bonnet, R. Thouvenot, AREVA NP Report No. NESH-G/2008/en/0123, 2008, http://www.epr-reactor.co.uk/ [Google Scholar]

- S. Zheng, J. Lonchampt, B. Winterholer (unpublished) [Google Scholar]

- V.G. Snell, J.Q. Howieson, Chernobyl – A Canadian perspective (AECL, 1991) [Google Scholar]

- J. Griffiths, Atomic Energy of Canada Ltd. Report No. RC-1776, 1994 [Google Scholar]

- B. Rouben, Atomic Energy of Canada Ltd. Report No. AECL-11407, 1996 [Google Scholar]

- G. Marleau, R. Roy, A. Hebert, École polytechnique de Montréal Report No. IGE-157 Montreal, Canada, 1993 [Google Scholar]

- A. Hebert, D. Sekki, R. Chambron, École polytechnique de Montréal Report No. IGE-300 Montreal, Canada, 2016 [Google Scholar]

Cite this article as: Ross Peel, Luc Van Den Durpel, Mark Daniel Ogden, Karl Rhys Whittle, Three-component U-Pu-Th fuel for plutonium irradiation in heavy water reactors, EPJ Nuclear Sci. Technol. 2, 29 (2016)

All Tables

Calculated relative reproduction factors and fission:capture ratios for two and three-component mixed oxide (MOX) concepts with 1, 2 and 3% by mass plutonium loading in MOX fuel elements.

Annual and 30-year fuel materials requirements per enhanced CANDU-6 with proposed three-component fuel.

All Figures

|

Fig. 1 Left: photograph of 43-fuel element CANFLEX fuel bundles; right: diagram showing CANFLEX fuel elements in pressure tube (red) with annular gas space (green) contained within calandria tube (orange). |

| In the text | |

|

Fig. 2 Evaluated values of neutronic factors as affected by dysprosium burnable absorber loading in UK CANMOX fuel. |

| In the text | |

|

Fig. 3 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 17, comprising a mixed oxide fuel of UO2-fuelled EPR reprocessed uranium and plutonium in the seed region and natural thorium oxide in the blanket region of the CANFLEX fuel bundle. |

| In the text | |

|

Fig. 4 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 19, comprising a mixed oxide fuel of UK inventory plutonium and ThORP product uranium in the seed region and natural thorium oxide in the blanket region of the CANFLEX fuel bundle. |

| In the text | |

|

Fig. 5 Evaluated values of neutronic factors affected by plutonium loading in proposed fuel concept 19 with blended uranium produced from 5600 te TPU and 4700 te MDU. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.