| Issue |

EPJ Nuclear Sci. Technol.

Volume 11, 2025

Euratom Research and Training in 2025: ‘Challenges, achievements and future perspectives’, edited by Roger Garbil, Seif Ben Hadj Hassine, Patrick Blaise, and Christophe Girold

|

|

|---|---|---|

| Article Number | 37 | |

| Number of page(s) | 5 | |

| DOI | https://doi.org/10.1051/epjn/2025037 | |

| Published online | 22 July 2025 | |

https://doi.org/10.1051/epjn/2025037

Regular Article

ASVAD

A new safety element to avoid the complications of the undesired nitrogen injection to PWR reactors

ASVAD INTL SL Tarragona Spain

* e-mail: alaborda@asvad-nuclear.com

Received:

20

February

2025

Received in final form:

1

May

2025

Accepted:

27

June

2025

Published online: 22 July 2025

During a Long-Term Station Blackout (LTSBO) accident like the Fukushima accident, the main way to remove decay heat from Pressurized Water Reactors (PWRs) is the Steam Generators (SGs). During these accidents, a Loss of Coolant Accident (LOCA) can also occur, as the main pump seals degrade quickly without proper cooling. To cope with LOCA, all current PWRs are equipped with 3 or more accumulators. Each accumulator consists of a tank filled with subcooled borated water. These tanks are pressurized with nitrogen to a pressure of around 4.5 MPa. When the primary pressure falls below the initial accumulator pressure, its water is pushed by the pressurized nitrogen into the primary system, increasing the mass inventory and cooling the reactor. This system has the advantage of being fully passive. However, nitrogen may flow into the primary system once the water has been depleted. To avoid gas intrusion, the isolation valve must be closed in time. However, this is very difficult to do when there is no power. If the valve isn’t closed in time and successfully, nitrogen will enter the primary system as soon as the accumulator is depleted. This nitrogen soon reaches and accumulates in the SG tubes. Here, the gas will significantly decrease steam condensation, which is the main method of cooling the core. This leads to a sudden increase in primary pressure and a strong decrease in natural circulation, threatening core cooling. To avoid all these complications, a special valve has been designed. The ASVAD valve is fully passive and automatic. It automatically vents the nitrogen at the correct moment, when the accumulator empties, preventing nitrogen from reaching the SG tubes. Being fully passive and automatic guarantees its proper operation without any operator action even during LTSBO scenarios. With ASVAD, operators are relieved from managing nitrogen injection and can remain focused on recovery tasks. By allowing further primary depressurization, the valve facilitates accident recovery, gives a longer coping time. The overall safety of the PWR reactors can be improved by installing ASVAD on each accumulator.

© A. Laborda, Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1. Introduction

This paper introduces a new technology rather than engaging in a detailed scientific discussion of the issues caused by non-condensable gases in a nuclear reactor. Although it does not strictly meet all the requirements for a scientific publication, its diffusion is valuable to show this new and original solution to the Nuclear community.

There is a serious complication with a high probability of occurrence during a Station Blackout (SBO) or a Loss of Coolant Accident (LOCA): the inflow of nitrogen into the Reactor Coolant System (RCS) from the accumulators.

The nitrogen inside the system can seriously disturb core cooling by disrupting the natural circulation in the Steam Generators (SGs), among other complications.

The current strategies to avoid this injection rely on active elements and operator actions:

-

Closing the accumulator output isolation valve.

-

Opening the accumulator relief valve.

-

Maintaining the RCS pressure above the residual nitrogen pressure.

The ASVAD valve [1] is an innovative safety valve that can easily avoid this problem. This valve is a passive and automatic element that can precisely detect the correct moment to act by monitoring the residual pressure in the accumulator. Only when the accumulator is empty, does the valve opens and vents the nitrogen into containment, making sure that nitrogen will never reach the RCS pipes.

The ASVAD valve provides the following main advantages:

-

it is a passive device and does not require any external energy to actuate.

-

It is fully automatic and does not need any operator assistance.

-

It actuates at the required moment–just when the accumulator is nearly depleted.

-

It is available at all times, protecting the RCS from nitrogen.

-

It allows depressurization of the RCS to lower pressures, thus diminishing the leakage rate and facilitating recovery.

2. The nitrogen threat

Nitrogen is a gas widely used in PWR pressurized accumulators, make-up tanks, or similar equipment systems. It allows passive water injection into the RCS when a LOCA depressurizes the system. However, once its function is complete, it must be isolated to prevent it from entering the RCS pipes. If this isolation is not performed in time, the gas can seriously threaten core cooling and fuel integrity.

Once nitrogen reaches the RCS, it unleashes several complications (see refs [2–17]):

-

natural circulation in the SGs diminishes or even stops, and heat transfer is seriously reduced by the presence of nitrogen.

-

RCS pressure rises–and remains high–due to nitrogen expansion caused by heating. This will hinder or even impede the low-pressure pumps from injecting into the RCS.

-

Nitrogen can even reach the Residual Heat Removal (RHR) pumps, rendering them inoperable.

-

If the temperature rises enough, nitrogen will accelerate fuel cladding oxidation [7].

In the event of an SBO accident, nearly all plant equipment is lost. Under these circumstances, only passive elements operate. The principal way to maintain core cooling is through the SGs by natural circulation. Unfortunately, this SBO accident triggers another serious accident: a LOCA. As this leak is permanent, sooner or later the water in these accumulators runs out, and at that moment, the nitrogen threat begins. If the RCS pressure cannot be maintained above the nitrogen pressure, nitrogen will start to enter the RCS pipes, soon reach the core, and disseminate throughout the system, eventually reaching the SGs and rendering them useless for cooling the RCS.

Why does this nitrogen injection have a high probability of occurring?

-

Because the LOCA is permanent, and the RCS pressure will drop constantly (unless operator actions can temporarily stop this drop).

-

Because nitrogen is already inside the system–and in large quantities!

-

Because it has an open and direct path to the reactor.

-

Because it is constantly attempting to enter the RCS; it only needs a moment of low pressure.

-

Because the only element able to stop it–the accumulator isolation valve–is an active element that requires energy to close.

Therefore, it is only a matter of time before nitrogen enters the RCS and disturbs core cooling. These are not merely assumptions or opinions; there have been some notable events in the past related to nitrogen intrusion in the pipes [6].

3. Current strategies

To prevent this nitrogen from reaching the RCS pipes, only three strategies may be employed [18, 19]:

-

closing (on time) the accumulator output isolation valve.

-

Venting (on time) the residual nitrogen to the containment building.

-

Maintaining the RCS pressure above the nitrogen pressure.

All these strategies have common drawbacks or weaknesses during an SBO accident.

They require the deployment and proper actuation of active elements such as FLEX AC generators, FLEX pumps and compressors, isolation or venting valves, and all their support systems. Since all these elements are active, they need energy to operate.

They also require operator intervention. These elements are not automatic; they must be deployed and operated by recovery personnel. This necessitates not only significant organizational effort, but also sound procedures and a well-trained team to implement the recovery strategies.

These strategies have another important drawback: TIME. It is not easy to determine when isolation should occur. If done too soon, some water will be wasted in the accumulator. If done too late, nitrogen injection will occur. Moreover, these actions must be performed simultaneously for all accumulators, as they work in parallel, making these strategies timecritical.

All these strategies rely on a long chain of active components (operators included). If something fails in this chain, nitrogen injection will occur. A good example is the isolation valves: even when closed, they leak nitrogen throughout the recovery because they are not gas-tight.

The last strategy–maintaining the RCS pressure–is only a temporary measure. Sooner or later, the RCS will be fully depressurized, and then one of the two previous strategies must be employed (with all its drawbacks).

4. The ASVAD valve

The (ASVAD) Automatic Safety Valve for Accumulator Depressurization [1] is the response to the nitrogen injection issue. It is a unique kind of safety valve, with one main difference from standard safety valves: the ASVAD only actuates when the pressure drops below a present level. This level can be adjusted to correspond to the point at which the accumulator becomes empty of water.

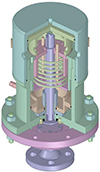

Figure 1 is an internal view of the valve's components. Figure 2 is a simplified representation of the ASVAD valve. It has a pressurized chamber (1) connected to the accumulator's nitrogen side. This chamber is sealed by a hollow obturator (2) and a gasket. A preloaded spring (3), whose preload is adjusted by an adjustment disc (4) threaded over the obturator, is also present.

|

Fig. 1. Inner view of the ASVAD valve internal elements. |

|

Fig. 2. ASVAD valve simplified operation diagram. |

The operation of the ASVAD valve is based on the imbalance between the forces exerted on the obturator. On the bottom side, the accumulator's internal pressure exerts a force that firmly pushes up the obturator, keeping it closed. On the upper side, the preloaded spring exerts a constant force that pushes the obturator downward, attempting to open it. As long as the force exerted by the accumulator's normal pressure (thick arrow) is greater than the force exerted by the spring (thin arrow), the obturator remains firmly closed. During normal operation, the force ratio is 3:1.

The spring is pre-set to match the force of the nitrogen pressure when the accumulator is empty. When these conditions are with the accumulator nearly depleted, the spring overcomes the force exerted by the residual pressure and suddenly pushes down the obturator. This opens a communication channel from the pressure chamber (1) through the obturator holes and its hollow body to the outside. Once the obturator has left its seat, the pressure in the chamber falls further, leaving the valve permanently open due to the continuous spring action.

This is a very simple principle, with a passive and automatic operation. Simplicity means also reliability.

Additionally, the valve has also other optional elements to allow its remote manual operation (open & close), but usually is not needed.

The ASVAD Valve has the following advantages.

Main advantages:

-

the ASVAD Valve will be available at all times after its installation, always waiting for its moment to act.

-

It completely prevents nitrogen injection.

-

It is based on two simple and universal physical principles (force and pressure).

-

It is fully passive; it does not require any external energy.

-

It is fully automatic; it does not need any operator assistance.

-

It acts at the right time and across all accumulators. No time-critical operations are needed–it does so automatically by sensing the accumulator pressure. It is also able to self-adapt its opening point to the existing environmental conditions, maximizing the water volume injected from the accumulator.

-

It completely vents the accumulator, so no further nitrogen injections will be possible.

-

It allows depressurization of the RCS to lower pressures, which will greatly facilitate further accident recovery (this could be its best advantage).

-

It will save the organization's efforts, allowing them to focus on other recovery tasks.

-

It does not interfere with normal operation.

Secondary advantages:

-

it is highly reliable due to its simple and robust design and physical operating principle.

-

It is robust enough to withstand the post-LOCA environment; it is made of stainless steel.

-

It is very easy to install in the system and does not require significant modification.

-

It does not add any new failure modes beyond those already analyzed.

-

It is intrinsically safe, with no electromagnetic issues. It's fireproof, does not add any fire load, it is not sensitive for radiation, moisture, or flooding.

-

It also has a manual operation feature; it can be remotely actuated when required.

-

It's maintenance is simple. There is no wear. It just requires a few spare parts. Minimum maintenance cost.

-

The desired actuating pressure is easy to adjust and check.

-

It is economical and does not require complex or expensive system modifications.

-

It's qualified life is very long.

About the ASVAD Valve problems:

no specific problems are known yet, as its simplicity implies that there are few elements that can fail. A possible problem during operation could occur if the valve leaks nitrogen to the atmosphere.

However, this kind of problem is extremely unlikely and very easy to fix by isolating the valve. It must be taken into account that as long as there is enough pressure in the accumulator, the closing force will keep the obturator firmly closed. Another unlikely problem is if the obturator gets stuck in the closed state. The obturator geometry makes this kind of failure extremely improbable, as there is no way for any pollution to enter the valve.

5. Termohidraulic analysis of ASVAD behaviour

Few analyses of the ASVAD valve performance have been carried out yet. The main one is reference [1] which studies the beneficial effect of the valve during a Reactor bottom LOCA. This study evaluates how the ASVAD valve can solve a former experiment, test 6–2 from the OECD/NEA ROSA-1 project, carried out at the Large Scale Test Facility (LSTF) in Japan.

This experiment had to be aborted to protect the installation due to the negative effects of nitrogen. In the conclusion, the simulation shows that using ASVAD, the core damage would have been avoided.

Other more recent analyses [20] were done by the Spanish Nuclear Regulator (Consejo de Seguridad Nuclear). They thoroughly evaluated both, the constructive aspects of the valve, and its expected effects on design accidents at Westinghouse PWR-type power plants. They have given their approval to the use of the ASVAD valve in the Spanish Nuclear Plants.

Unfortunately, this study is not published due to its proprietary nature. Nevertheless, it can be directly provided by the author when asked.

6. Conclusions

Nitrogen injection into the RCS is a complication that can seriously threaten core cooling and fuel integrity during an SBO/LOCA accident. It is highly likely to occur during an SBO.

The current strategies to avoid it are too weak to be relied on. All of them use active components that require energy and multiple operators to perform time-critical actions simultaneously on different elements. This is like a chain: if any link fails, the whole operation fails.

Using ASVAD, nitrogen injection into the RCS can be easily avoided. ASVAD allows operators to be freed from dealing with this issue. This way, they can remain focused on core cooling or other recovery tasks. By allowing further RCS depressurization, it can facilitate accident recovery, giving a longer coping time.

ASVAD is a passive device that automatically vents the nitrogen at the correct moment. Overall plant safety can be improved by installing this valve on each accumulator.

Acknowledgments

The author acknowledges the help of the company Ringo Valves (Samson group) who made real this project, by building and testing the first ASVAD prototype. He also acknowledges the contribution of the staff from the Universidad Politecnica de Cataluña (UPC) and the Consejo de Seguridad Nuclear (CSN) who evaluated the ASVAD's performance.

Funding

All the work presented in this paper was carried out by the author without any financial support from third parties.

Conflicts of interest

All the work of this paper was done in accordance with the ethical standards of scientific communications. There are also other interests besides improving PWR reactors safety. The ASVAD valve is patented in different countries. Patent rights protect all the work involved in its development. The author controls the ASVAD patent, and this represents his legitimate interest.

Data availability statement

Any additional data about the aspects of the non-condensable behaviour inside the reactor cooling systems, or the current strategies to avoid it, can be found in the referenced documents. Additional data, detailed descriptions, and test results about ASVAD valve can be found at www.asvad-nuclear.com or directly asking the author.

Author contribution statement

As there is only one author, all the work was done by Arnaldo Laborda.

References

- J. Freixa, A. Laborda, V. Martinez, Effectiveness of the ASVAD valve in a RPV bottom leak, Ann. Nucl. Energy (2021), https://authors.elsevier.com/sd/article/S0306454921002632 [Google Scholar]

- C. Sarrette, Effect of Noncondensable Gases on Circulation of Primary Coolant in Nuclear Power Plants in Abnormal Situations (Lappeenranta University of Technology, Finland, 2003) [Google Scholar]

- T. Nagae, T. Chikusa, M. Murase, N. Minami, Analysis of non-condensable gas recirculation flow in steam generator U-tubes during reflux condensation using RELAP5, J. Nucl. Sci. Technol. 44, 1395 (2007) [Google Scholar]

- L. Yuquan, H. Botao, Z. Jia, W. Nan, Comparative experiments to assess the effects of accumulator nitrogen injection on passive core cooling during small break LOCA, Nucl. Eng. Technol. 49, 54 (2017) [Google Scholar]

- T. Takeda, A. Ohnuki, D. Kanamori, I. Ohtsu, ROSA/LSTF tests and RELAP5 posttest analyses for PWR safety system using SG's secondary – side depressurization against effects of release of nitrogen gas dissolved in accumulator water, Sci. Technol. Nucl. Install. 2016, 7481793 (2016) [Google Scholar]

- Various Authors, Various incidents in the US plants related with nitrogen. NRC GL-2008-01, IN-97-40, IN-89-67, ML031050497, ML031060539, ML031180745, ML090980303 [Google Scholar]

- M. Steinbrueck, F. Oliveira da Silva, M. Grosse, Oxidation of Zircaloy-4 in steam-nitrogen mixtures at 600–1200°C, J. Nucl. Mater. 490, 226 (2017) [Google Scholar]

- S. Gallardo, V. Abella, G. Verdu, Assessment of TRACE 5.0 against ROSA Test 6-2, Vessel Lower Plenum SBLOCA, Tech. Rep. (2011) [Google Scholar]

- J. Kang, B. Yun, An experimental study of steam condensation with the presence of air under free convection condition, in Nureth-18 (2019), pp. 1893–1906 [Google Scholar]

- J. Lee, G.-C. Park, H.K. Cho, Validation of wall film condensation model in the presence of NC gas for two-fluid model, in NUTHOS-11 (2016), pp. 1–15 [Google Scholar]

- K.-W. Lee, H. C. No, I.-C. Chu, Y. M. Moon, M.-H. Chun, Local heat transfer during reflux condensation mode in a U-tube with and without noncondensible gases, Int. J. Heat Mass Transf. 49, 1813 (2006) [Google Scholar]

- T.-J. Liu, Reflux condensation behavior in a U-tube steam generator with or without noncondensables, Nucl. Eng. Design 204, 221 (2001) [Google Scholar]

- H.-S. Park, H.C. No, Y.S. Bang, Analysis of experiments for in-tube steam condensation in the presence of noncondensable gases at a low pressure using the RELAP5/MOD3.2 code modified with a non-iterative condensation model, Nucl. Eng. Design 225, 173 (2003) [Google Scholar]

- V. Riikonen, V. Kouhia, O. Kauppinen, H. Sjovall, J. Hyvarinen, Experimental observation of adverse and beneficial effects of nitrogen on reactor core cooling, Nucl. Eng. Design 332, 111 (2018) [Google Scholar]

- T. Takeda, M. Suzuki, H. Asaka, H. Nakamura, Quick-look Data Report of OECD/NEA ROSA Project Test 6-2 (0.1% 15 Pressure Vessel Bottom Small Break LOCA Experiment), Tech. Rep. JAEA-Research 2006-9002 (Japan Atomic Energy Agency, 2006) [Google Scholar]

- J. Yeong-Jun, C. Dong-Jae, L. Yeon-Gun, K. Sin, J. Dong-Wook, Experimental study of condensation heat transfer in the presence of noncondensable gas on the vertical tube, in International Topical Meeting on Nuclear Reactor Thermal Hydraulics 2015, NURETH 2015 7 (2015), pp. 6096–6109 [Google Scholar]

- The ASVAD Valve: visit www.asvad-nuclear.com [Google Scholar]

- Various Authors, WCAP-17601-P Rev.1, Reactor Coolant System Response to the Extended Loss of AC Power Event for Westinghouse, Combustion Engineering and Babcock & Wilcox NSSS Designs, Westinghouse Proprietary Class 2, (2013) [Google Scholar]

- Various Authors, FSG-10 Rev.1, Passive RCS injection isolation, Background information for Westinghouse Owners Group Emergency Response Guidelines, PWROG, (2014) [Google Scholar]

- The ASVAD Valve validation by the Spanish Consejo de Seguridad Nuclear (CSN): CSN/C/SG/TGE/24/05. INSI/OTROS/2022/128 02/02/2024 [Google Scholar]

Cite this article as: Arnaldo Laborda. ASVAD. A new safety element to avoid the complications of the undesired nitrogen injection to PWR reactors, EPJ Nuclear Sci. Technol. 11, 37 (2025). https://doi.org/10.1051/epjn/2025037

All Figures

|

Fig. 1. Inner view of the ASVAD valve internal elements. |

| In the text | |

|

Fig. 2. ASVAD valve simplified operation diagram. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.