| Issue |

EPJ Nuclear Sci. Technol.

Volume 11, 2025

Euratom Research and Training in 2025: ‘Challenges, achievements and future perspectives’, edited by Roger Garbil, Seif Ben Hadj Hassine, Patrick Blaise, and Christophe Girold

|

|

|---|---|---|

| Article Number | 25 | |

| Number of page(s) | 11 | |

| DOI | https://doi.org/10.1051/epjn/2025021 | |

| Published online | 09 June 2025 | |

https://doi.org/10.1051/epjn/2025021

Regular Article

Advancing Gas-cooled Fast Reactor Technology: Outcomes of the Euratom SafeG Project on ALLEGRO Research and Development

1

VUJE, a. s., Okružná 5, Trnava 918 64, Slovak Republic

2

HUN-REN Centre for Energy Research, 1525 Budapest 114, P.O. Box 49, Budapest, Hungary

3

ÚJV Řež, a. s., Hlavní 130, Řež, 250 68 Husinec, Czech Republic

4

Centrum Výzkumu Řež s.r.o., Hlavní 130, 250 68 Husinec- Řež, Czech Republic

5

Department of Engineering, University of Cambridge, Trumpington Street, Cambridge CB2 1PZ, United Kingdom

* e-mail: boris.kvizda@vuje.sk

Received:

15

November

2024

Received in final form:

29

January

2025

Accepted:

23

April

2025

Published online: 9 June 2025

The paper describes R&D activities suported by Euratom funded projects (SafeG, TREASURE) focused on advancing the development of the Gas-cooled Fast Reactor (GFR) demonstrator ALLEGRO, a key technology in the Generation IV nuclear reactor systems. With the backing of the Generation IV International Forum (GIF) and European Sustainable Nuclear Industrial Initiative (ESNII) of the Sustainable Nuclear Energy Technology Platform (SNETP), GFR technology promises high efficiency in both electricity and industrial heat production, owing to its ability to achieve high core outlet temperatures and close the fuel cycle. The presented activities revolve around addressing crucial technical challenges linked to the ALLEGRO demonstrator. The described projects have brought together leading European and international experts in GFR and High-Temperature Reactor (HTR) technologies. The key outcomes of the SafeG Project include advancements in core safety (WP1), innovative materials (WP2), passive safety systems (WP3), standardization and codes (WP4), and education and training activities (WP5). The future activities are outlined for the follow-up Project TREASURE.

© B. Kvizda et al., Published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1. Introduction

A GFR is recognized as one of the six most promising advanced nuclear reactor technologies, selected by the Generation IV International Forum (GIF). The technology is supported by ESNII (European Sustainable Nuclear Industrial Initiative) within the SNETP (Sustainable Nuclear Energy Technology Platform). This advanced reactor concept is designed to provide a highly efficient and sustainable energy solution, with the potential to meet both electricity and industrial heat demands. One of the key advantages of GFR technology is its ability to operate at very high core outlet temperatures, which significantly improves thermal efficiency. Furthermore, GFR supports a closed fuel cycle, enabling the recycling of nuclear fuel and minimizing radioactive waste, contributing to long-term sustainability and resource efficiency in nuclear energy production.

The representative of GFR technology is the ALLEGRO demonstrator (Fig. 1). Its development is governed by the consortium V4G4 Centre of Excellence, established in 2012, connecting four institutes from central European countries (EK, NCBJ, UJV Řež, VUJE) and two associate members (CEA, CVR). The ALLEGRO development is supported by Euratom through the SafeG (No. 945041; https://cordis.europa.eu/project/id/945041) and TREASURE (No. 101164616; https://cordis.europa.eu/project/id/101164616) projects. Other relevant national research programs are ongoing in parallel.

|

Fig. 1. ALLEGRO 75 MW. |

The SafeG project (2020–2024) [1] was initiated as a research and innovation action aiming at acceleration of ALLEGRO R&D. It is a small-scale GFR prototype and represents an essential step toward demonstrating the feasibility of GFR technology and validating its performance in operating conditions. The SafeG project connects V4G4 members with European and international experts who possess substantial experience in GFR and HTR research, altogether 15 members. By leveraging this collective expertise, SafeG seeks to address existing technical challenges in GFR development while introducing innovative ideas and relevant know-how to enhance ALLEGRO safety.

The project is organized into seven Work Packages (WPs), each targeting a critical aspect of GFR development. The first four WPs focus on resolving open R&D issues related to core safety and proliferation resistance (WP1), advanced materials and technologies (WP2), innovative solutions for Decay Heat Removal (DHR) including experimental verification on S-Allegro test facility (WP3), and the integration of results and standardization (WP4). In addition, education and training activities are sheltered by WP5, ensuring the involvement of students and young professionals and fostering a new generation of nuclear engineers and researchers. WP6 covers dissemination and outreach activities, aiming to increase the visibility and impact of GFR research, while WP7 ensures smooth project management and execution.

The important objectives of the SafeG project were:

-

to strengthen safety of the GFR demonstrator ALLEGRO, core design optimization.

-

To review the GFR structural materials and advanced technologies for the key components.

-

To enhance the performance of the DHR system in accident conditions, leading to the practical elimination of severe accidents.

-

To propose innovative methods for instrumentation and control.

-

To experimentally verify the DHR performance using the test facility S-Allegro.

-

To bring in students and young professionals and boost their interest in GFR research.

-

To deepen the collaboration with international non-EU research teams and relevant European and international bodies.

The TREASURE project (2024–2028) is a follow-up project of the SafeG.

The main objectives of the TREASURE project are:

-

further optimization of the GFR fuel design and fuel cycle.

-

Explore possibilities to further reduce produced waste and to further enhance proliferation resistance in GFRs.

-

ALLEGRO safety concept demonstration, including large-scale experimental verification.

-

Optimization of operation flexibility and performance of GFRs, using intermediate heat storage system, cogeneration, and hydrogen production.

-

Further enhancing ALLEGRO safety via use of passive and redundant safety systems.

-

Attracting students and young professionals to work on GFR development.

2. ALLEGRO design

ALLEGRO is a concept of a demonstration unit of the GFR technology. Its main goal is to prove the viability, safety, and reliability of the whole concept of a gas-cooled reactor with a fast spectrum. It is important to mention here, that, despite the history of GFR development being surprisingly rich with many concepts originating as far into history as the 1960's, no such reactor has ever been built and operated. It was originally designed by the French Alternative and Atomic Energy Commission (CEA) as the Experimental Technology Demonstration Reactor (ETDR) [2, 3] with a power of 50 MWth. The ALLEGRO project, a 75 MWth reactor that evolved from the ETDR concept, was led by CEA until 2010. Then, the preparations for know-how transfer from CEA to the Visegrád group (V4) countries, based on the Memorandum of Understanding, started. The main technical features of ALLEGRO are listed in Table 1, and a cross-section of the facility is in Figure 2. Detailed description can be found in [4].

|

Fig. 2. ALLEGRO system arrangement. |

Main design parameters of ALLEGRO.

3. The core safety and optimisation

3.1. Material and methods

The ALLEGRO reactor has two consecutive cores: the so-called driver core and the refractory core. The inlet and outlet coolant temperature of the driver core is 260 and 520°C respectively. It has UOX or MOX fuel with stainless steel cladding. The refractory core inlet coolant temperature is 400°C while its outlet temperature is 800°C and it has carbide fuel and silicon carbide (SiC) cladding.

The optimization methodology is an iterative task between neutronics, thermal hydraulics, and thermomechanics. A list of initiating events was defined based on CATHARE2 thermal-hydraulic calculations [5], previous studies [2], and engineering judgment. Four initiating events were selected for ALLEGRO core optimization:

-

TR15 – Protected hot duct break transient aggravated by the single failure of the inadvertent opening of a DHR loop in which the blower is not started.

-

TR16 – Protected 10-inch LOCA aggravated by the single failure of the inadvertent opening of a DHR loop in which the blower is not started.

-

TR20 – Unprotected 3-inch LOCA.

-

TR22 – Unprotected control rod group withdrawal.

The acceptance criteria for fuel and cladding were defined in [6]. For neutronic calculations, the SERPENT Monte Carlo and the KIKO3DMG nodal code were used.

3.2. Results

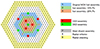

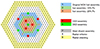

As mentioned earlier both the driver and the refractory core were optimized. During the optimization of the MOX core, the Pu content of fuel assemblies was varied to flatten the radial power distribution. Fuel assemblies with three different Pu contents were used, and the number of fuel assemblies was increased from 81 to 111, the core is referred to as MOX_v2. The target of the optimization was to decrease the maximum assembly power from 1.14 MW to around 0.74 MW (0.78 MW is reached). The SiC Displacements Per Atom (DPA) rate of the core is 10.8 DPA/year, which is above the 8 DPA/year design requirement. The maximum cycle length of the core is 641 days, and the node-wise maximum burnup at the End of Cycle is around 18 MWday/kgHM. The decay heat curves were calculated for different burnup steps using Serpent. The control rod reactivity worth was calculated. The core safety parameters were calculated for the Beginning Of Cycle of the core, and conservative frame parameters were determined to get the input of the safety analysis. The optimized MOX_v2 core defined by EK meets the SiC DPA rate requirement and satisfies the preliminary requirement for the maximum power density. Figure 3 shows the new optimized MOX_v2 core.

|

Fig. 3. The optimized ALLEGRO MOX_v2 core. |

Parallel with the MOX core optimization the UOX core [7] was also optimized. The maximum UOX enrichment was 19.5%, because of the 20% proliferation limit. Compared with the ALLEGRO CEA MOX concept, the UOX core19 core is larger - one ring of fuel assemblies was added. Fuel pellet diameters are extended as well – +19% for core 19. The objectives of optimization were as follows:

-

to have power peaking at UOX fuel as low as possible.

-

To keep DPA values at UPuC fuel S/A as high as possible.

-

The uranium enrichment varies from 17.4% to 19.5%.

The safety analysis for both MOX and UOX cores showed reasonable results using the best estimate methodology for most of the cases. On the other hand, it was pointed out that further iteration is needed when the conservative methodology is used.

Following a series of CATHARE thermal-hydraulic (TH) calculations for different core powers for the reference refractory core, a maximum allowable core power can be defined for the hot duct break transient. Using this data the maximum linear heat rate can be defined, which was an input for refractory core optimization.

In the case of refractory core [8] optimization, we supposed that the fuel sub-assembly geometry remains unchanged. We maintained the refractory core power at 75 MWth, but we lowered the average power density and created a more evenly distributed radial power with one extra ring of fuel sub-assemblies, using three different Pu contents (FU1: original, FU2: –10% Pu, FU3: –20% Pu). Using a genetic algorithm and the KIKO3DMG nodal code with six energy groups, a new refractory core configuration was selected among 1000 candidates.

3.3. Discussion

Both the driver and the refractory ALLEGRO cores were optimized. The safety analysis of the optimized driver core showed that the safety requirements are fulfilled when the best estimate methodology is used. Nevertheless, further studies are necessary for conservative safety analysis. Concerning the ALLEGRO core optimizations the following recommendations were proposed:

-

radial/axial heat transfer. Development of the best-estimate TH model.

-

Determination of the realistic heat exchange coefficient in the open gas-gap.

-

Determination of the realistic/conservative flow distribution in the core (gagging scheme).

-

Determination of the fuel assembly bypass and reflector and shielding bypass in the core during nominal operation by CFD code.

-

Determination of the core pressure drop for modified UOX and MOX cores by the CFD code.

-

Determination of the time constant of the core support plate which influences reactivity feedback contribution from the core diagrid expansion effect.

-

CSD S/As optimization in terms of the reactivity worth.

-

Determination of the main blower inertia.

-

DHR loop flow resistance.

-

DHR loop thermal pre-conditioning.

-

Neutronic and safety analyses for the whole core fuel cycle.

-

Analyze the decay heat sources in detail.

-

Determination of the uncertainties (setpoints, delay) of the measuring chain for SCRAM and ESFAS.

-

Determine the frame parameters for the UOX core and estimate their uncertainties.

4. Advanced materials and technologies

The deployment of a GFR system crucially depends on the availability of innovative materials able to withstand harsh operational and accident conditions. The most important challenges connected with materials are:

-

radiation damage due to fast neutron spectra causes embrittlement, swelling, and cracking particularly for the core structures.

-

Material degradation due to long-lasting exposure to high temperatures leading to embrittlement, creep or cracking.

-

Thermal stresses due to thermal expansion and contraction in a wide range of temperatures causing fatigue or cracking.

-

Difficulty in manufacturing and fabricating leads to high costs.

-

Coolant compatibility. Helium is an inert gas but even small impurities (O2, H2O-vapor, CO) can accelerate chemical reactions with material structures.

Several groups of materials based on their deployment in the reactor have been selected. Nickel-based alloys (Alloy 617, Haynes 230, Alloy 625, 690), austenitic stainless steel and titanium-based alloys for the high temperature out of core components. The main candidate for GFR cladding, which has also been extensively studied is the ceramic composite SiCf/SiC, i.e., silicon carbide fibres in the silicon carbide matrix. However, the design rules and joining technique of SiCf/SiC cladding also need to be developed. SiC cladding material has low neutron capture cross section and excellent material properties at high temperatures. It is planned the SiC components will be used in GFR for so-called refractory core operated at very high temperatures (Fig. 4). The Kyoto University in cooperation with EK carried out a series of experiments and examinations with SiC cladding tubes, e.g. high-temperature treatment in He atmosphere, high-temperature oxidation in steam, ring compression tests, mandrel tests, pressurization and scanning electron microscopy. The results of testing SiCf/SiC composite tubes are promising and this is the primary candidate cladding material for the refractory fuel of GFR.

|

Fig. 4. Macrograph of the SiC/SiCf samples. |

Other innovative materials developed and tested within the project, were advanced manufactured IN 617 and the oxide-dispersion strengthened ferritic FeCrAl alloys. Different additively manufactured (AM) technologies were investigated by the SafeG project partner USFD to determine the feasibility of these advanced manufacturing processes for enabling the manufacturing IN617 and the feasibility of manufacturing the selected DHR heat exchanger (HX) component. AM IN617 samples were additively manufactured using arc-wire (AW), laser-powder (LP) and laser-wire (LW) directed energy deposition (DED) capabilities, and the powder bed fusion (PBF) process. The laser powder bed fusion (LPBF) equipment, which was used to fabricate representative samples for ongoing material characterization studies, was specially selected for the fabrication of DHR heat exchanger. The full HX component in reduced scale has been fabricated by using an advanced manufacturing process, given in Figure 5.

|

Fig. 5. DHR heat exchanger produced by advanced manufacturing process – material IN617. |

Project partner NCBJ developed, manufactured, and tested the FeCrAl-based alloys with Ti and V (maximum 1 and 0.5 wt.%) and Y2O3 oxide particles (Fig. 6) [13]. Tested samples of ODS FeCrAl exhibited excellent mechanical properties at elevated temperatures that were close to the operating temperatures specified for ALLEGRO.

|

Fig. 6. SEM backscattered electron images of microstructure of selected FeCrAl-ODS bulk samples. |

Within the SafeG project selected promising material candidates has been performed and some of the materials were experimentally tested in the simulated GFR environment. A high-temperature oxidation tests have been performed based on which the tested materials have been ranked in the following order: AFA > IN617 > Alloy 800H ∼ 15-15Ti > AM IN617: LP (LPBF, LPBFHP) ∼ AW > ODS FeCrAl. This ranking highlights that AFA steels are at the top of the performance spectrum, particularly in terms of oxidation resistance and mechanical integrity at high temperatures, followed closely by IN617. IN617 is a nickel-chromium-cobalt-molybdenum alloy known for its excellent oxidation resistance at high temperatures. Additive manufacturing methods such as DED and LPBF enhance control over the microstructure of IN 617. Investigated AM IN617 materials exhibit good oxidation resistance and mechanical properties, but the specific additive manufacturing process influences the HT performance. The ODS FeCrAl samples exhibit good oxidation resistance but moderate mechanical strength. Alloy 800H (a nickel-iron-chromium alloy) and 15-15Ti (austenitic stainless steel stabilized with titanium) both offer good resistance to oxidation. Alloy 800H has good high-temperature strength, while 15-15Ti provides excellent toughness and high-temperature tensile properties. However, these materials are inferior to IN617 or AFA steel. The primary goal of evaluating these advanced materials’ resistance to high-temperature environments, simulating the conditions of helium gas coolant in a GFR system, was successfully achieved. The results demonstrate the promising oxidation resistance of the newly developed AM IN617 produced via the LPBF process. However, further research and optimization of the powder manufacturing process are required to fully realize its potential.

5. Decay Heat Removal optimization

The innovative design of the DHR system, coming from one of the Czech national R&D projects complementing the SafeG project, was investigated and further refined within the WP3 of the project. The DHR system of ALLEGRO is composed of dedicated coaxial loops connected to the Reactor Pressure Vessel (RPV), featuring a gas/water heat exchanger, and a set of valves called the preconditioning device, that allows for continuous small coolant flow through the loop in normal reactor operation, keeping the DHR system ready at all times. In this configuration, the DHR system is a passive safety system that can remove the residual heat from the core in all the cases where the main blower is tripped. An overview of the DHR system and the principle of function of the preconditioning device are shown in Figure 7.

|

Fig. 7. Decay heat removal loop (left) and the principle of operation of the preconditioning device (right). |

In the project, it was shown, that the implementation of the system helps to keep a steady flow of coolant through the system at every moment of a postulated transient, which is crucial for successful cooling of the core during transients in GFR. A representative example of the effect of the implementation of the system is shown in Figure 8. The simulated scenario was the total station blackout (SBO). It can be seen from the graphs, that the primary mass flow rate never drops to values close to zero in the case of the innovative DHR system, and the power dissipated by the heat exchanger in the DHR loop is substantially higher, especially in the first minute of the transient.

|

Fig. 8. Comparison of mass flow rate of primary coolant (left) and power dissipated by the DHR loop (right) between the legacy and the innovative passive DHR system. |

6. Emergency Core Cooling System of ALLEGRO

The Emergency Core Cooling System (ECCS) plays an essential role in the ALLEGRO safety concept. The legacy ECCS design was proposed in [9] and its main purpose is to prevent the core from melting in Design Extension Conditions (DEC). The basic idea is to inject heavy gas (nitrogen) into the main system to keep core mass flowrate to facilitate heat removal during DEC scenarios including (a) LOCA combined with total station blackout, (b) LOCA combined with a leak from closed containment (Guard Vessel), (c) unprotected LOCA and (d) total rupture of the primary system cross duct. However, recent studies [5] revealed relatively narrow safety margins for the transients with activated nitrogen injection, particularly for the LOCA combined with the total station blackout. The optimization process for the ECCS legacy design was performed within the SafeG project [10]. The method applied includes the identification of the most relevant phenomena and corresponding time intervals of occurrence. Based on this the selection of the key input parameters, listed below, have been performed.

-

Time of the DHR transition sequence including set points to start the N2 injection.

-

Size of the N2 accumulator nozzle diameter.

-

Utilization of the helium make-up system prior to N2 injection from the ECCS tanks.

-

Positioning of the N2 injection lines inlet nozzles.

Except for those mentioned above, there have been a number of less relevant parameters in this study.

6.1. Results

For the selected input parameters a huge number of TH sensitivity analyses with the ALLEGRO CATHARE2 model have been performed. The utilized TH ALLEGRO model has been validated in the code-to-code benchmark [4]. Based on these simulations the modified ECCS injection system has been proposed and analytically tested. The main modifications of the ECCS include (a) passive injection from the helium make-up tanks prior to N2 injection, (b) earlier actuation of the N2 injection, (c) modification of the injection nozzle diameter, (d) modification of the injection point to the RPV.

The performance of the modified (f1 case) and legacy ECCS (Ref. case) was compared (Figs. 9 and 10). The proposed changes prevent the core from melting in the case of LOCA combined with SBO [10].

|

Fig. 9. Maximum fuel cladding temperature. |

|

Fig. 10. The mass flow rate in the hottest channel. |

Besides the above-mentioned TH calculations, a number of CFD simulations have been performed in order to select the most effective ECCS injection point [11]. The LOCA scenarios enveloping the break size in the range from 20 mm to 100 mm and injection nozzle diameter from 20 mm to 60 mm have been calculated with the CATHARE2 code. The data were used to set up boundary conditions for the CFD model. The reactor pressure vessel and connected primary ducts have been modeled in Ansys code. Two injection positions: (a) from the RPV side and (b) from the RPV elliptical bottom were investigated. The CFD simulations clearly showed that the optimal injection point for ECCS is the RPV elliptical bottom (Fig. 11). In this case, the injected gas flows directly to the core while in the case of side position, the injected medium is entrained towards the break on the primary system cold duct (see Fig. 12).

|

Fig. 11. Injection path lines for LOCA 100 mm at 28 s (RPV bottom point). |

|

Fig. 12. Injection path lines for LOCA 100 mm at 10 s (RPV side point). |

7. Experimental verification of DHR performance on S-Allegro Integral Test Facility

The Integral Test Facility (ITF) S-Allegro [12] is operated by CVR in Pilsen, Czech Republic. The facility, with a power input of 1 MW, is designed as a scaled-down model of a GFR. It comprises a 1 MW electrically heated reactor vessel, a primary and secondary helium loop with a design temperature of up to 850°C and a pressure of 7 MPa, as well as a tertiary water loop. Additionally, a dedicated vertical passive DHR loop is connected to the reactor vessel, enabling passive heat removal through the natural convection of helium.

Two comprehensive experimental campaigns were conducted during the SafeG project. The first campaign focused on assessing natural convection within the DHR loop and the reactor vessel at reduced pressure levels, corresponding to LOCA scenarios. Three steady states were established at pressures of 3.59 MPa, 4.07 MPa, and 4.77 MPa, maintaining a constant heating power level. Measurements of helium flow rates and temperatures along the DHR loop and within the reactor vessel were taken. Additionally, a transition from the main loop's operation to the passive DHR regime was successfully executed. Results indicated that natural convection in the DHR loop was established rapidly, within less than 60 seconds, which is a favorable outcome for the design of passive systems based on natural convection.

The second experimental campaign investigated the injection of heavy gas into the DHR loop during natural convection. The injection of heavy gas is considered a potential severe accident mitigation strategy that could enhance natural circulation in the DHR loop during LOCA incidents. This experiment can be regarded as the first of its kind at this scale. Due to its complexity, slow injection rates were employed to minimize thermomechanical stresses on the facility's structures. Four steady states were achieved, beginning with stabilized pure helium natural convection at 3.54 MPa, followed by nitrogen injections that increased pressure to three levels (3.92 MPa, 4.41 MPa, and 4.95 MPa). Similar to the previous campaign, flow rates of the gas mixture and temperatures were measured to evaluate the impact of heavy gas injection on the thermal-hydraulic behavior of the DHR loop. The results indicated a positive correlation between increasing pressure and nitrogen content with enhanced natural convection and improved heat removal from the reactor vessel.

Future experimental activities at the S-Allegro facility are anticipated, involving additional complex experiments aimed at simulating various operational and accident scenarios related to GFR systems, as well as supporting the benchmarking of thermal-hydraulic codes. A depiction of the S-Allegro ITF facility is shown in Figure 13.

|

Fig. 13. S-Allegro Integral Test Facility. |

8. Education and training activities

The education and training activities within the SafeG project were focused on on-the-job training for students and young professionals. The goal was to involve them in solving cutting-edge research problems and to attract new students by offering engaging PhD and master's theses with clear applications of their results.

Master's and Ph.D. theses related to the project, along with on-the-job training activities, were successfully conducted. Within the SafeG project, master's theses focused on various aspects related to the ALLEGRO gas-cooled reactor design, material studies, safety evaluations, and hydrogen production within the context of gas-cooled reactors. These theses demonstrated students’ engagement in diverse fields and contributed to the advancement of knowledge and technologies in specific areas of nuclear energy.

The Ph.D. theses within the SafeG project delved into specialized fields such as advanced safety analyses, thermal hydraulics, innovative fuel assemblies, and severe accident mitigation approaches (core catcher design) for gas-cooled reactors. The research conducted by Ph.D. students significantly contributed to the progression of knowledge and technologies in these specific domains within the realm of nuclear energy and reactor design.

Seven master's theses were assigned, of which two have already been successfully defended. At the doctoral level, three students are working on research and preparing their theses in the field of the GFR. By offering valuable learning opportunities, the project aims to foster the growth and development of students in the nuclear field, preparing them for successful careers in the industry or further academic research.

Several events were organized focusing on Ph.D. students and young professionals. A thermal-hydraulic modelling benchmark was organized within the SafeG project. This activity was divided into two parts: the TH system code benchmark and the CFD benchmark. The primary purpose of the benchmark was educational, but the developed S-Allegro models are intended for further use in ALLEGRO-related R&D activities. Many young professionals were involved in this activity, enhancing their modelling and computational skills. The results of the thermal-hydraulics benchmark have been finalized and submitted.

The GFR Summer School was organized within the SafeG project WP5 at Centrum Výzkumu Řež (CVR), Czech Republic, in 2022. The 4-day event included technical lectures by SafeG experts and technical tours. Participants were students and young professionals from research or academic institutions involved in the SafeG project, as well as those outside the project. The lectures covered a wide range of topics related to the GFR, such as reactor concept and design, safety, materials, neutronics modelling, core layout, and thermal hydraulics. A major part of the school focused on practical exercises and hands-on experiments at CVR facilities.

Following the success of the first Summer School on GFR, the Advanced Modelling Techniques Workshop was organized within the SafeG project WP5 at the University of Cambridge, United Kingdom, in 2023. The 3.5-day workshop featured technical sessions, cultural visits, a networking social event, and a technical tour. The workshop successfully met its objectives of sharing experience, networking, and disseminating knowledge generated within the SafeG project. Lectures delivered by experts and professors covered a wide range of topics, including historical reviews and experiences of GFR, GFR design and technology, modeling methods and codes, CFD, and thermal hydraulic analysis. These sessions facilitated fruitful discussions between senior experts and young professionals from diverse research backgrounds.

Participants provided overwhelmingly positive feedback regarding both the organization and technical content of both events. The program effectively achieved the goals outlined in the work package. The number of participants at both events exceeded expectations, even at the upper bound of our Key Performance Indicator. The highest KPI for this event, defined in the project proposal, was achieved (>25 participants is considered “excellent”). To further promote the project and expand our outreach, we shared highlights of the workshop on LinkedIn following its conclusion.

9. Future research and development

Since 2024 the ALLEGRO reactor development continues under Euratom project TREASURE. The ambition is to bring the ALLEGRO demonstrator concept closer to realization by solving open issues in the safety concept. We plan to perform complex experiments and prototype testing in the S-Allegro ITF. Another task is to tackle issues connected to GFR technology in general, such as the possibility of using the produced high-temperature heat on an industrial scale while keeping the reactor operation safe and reliable at the same time. There are even more such as issues connected with nuclear waste production minimization, multiple recycling of the nuclear fuel, and easy and fast decommissioning by design in the future.

The TREASURE project is structured into work packages in a way that allows reliable verification of the project outcomes against established goals:

-

core safety and operation optimization (WP1).

-

Experimental qualification of simulation tools for Decay Heat Removal concept (WP2).

-

Application of GFR as an industrial power and heat source (WP3).

-

Enhancing GFR safety (WP4).

-

Dissemination, communication, and education (WP5).

The main objectives of the TREASURE project will be achieved through a set of targeted research and development activities focusing on newly emerged topics such as the need for flexibility of operation of nuclear reactors, or those that have not yet been thoroughly investigated in GFRs and ALLEGRO specifically. These activities cover the following areas and specific project objectives:

-

further optimization of the GFR fuel design and fuel cycle.

-

Exploring possibilities to further reduce produced waste and to further enhance proliferation resistance in GFRs.

-

ALLEGRO safety concept demonstration, including large-scale experimental verification.

-

Optimization of operation flexibility and performance of GFRs, using intermediate heat storage system, cogeneration, and hydrogen production.

-

Further enhancing ALLEGRO safety via the use of passive and redundant safety systems.

-

Attracting students and young professionals to work on GFR development.

One of the project objectives is to reach a significantly higher level of maturity of the GFR technology, and its European demonstration unit ALLEGRO by following the safety-by-design approach. It will be achieved through the continuation of a very successful and long-term international collaboration on the development of the GFR technology in Europe. The project will showcase that an advanced reactor of GFR type can be designed and operated efficiently and that it may significantly contribute to the transition to sustainable low-carbon energy production while being coherent with all the safety standards and requirements for modern advanced reactors.

A major effort is expected to be put into tasks proving that GFR can be operated reliably, and in a versatile manner, expanding the list of potential customers of its industrial units in the future. The combination of the production of high-temperature heat suitable for various industrial processes with high-efficiency electricity cogeneration, while keeping the produced spent fuel and other waste at a minimum, are the main features of the GFR technology, and the TREASURE project will contribute to further demonstrate these abilities.

Acknowledgments

The SafeG project has received funding from the Euratom Research and Training Programme 2014–2018 under grant agreement No 945041. The TREASURE project has received funding from the Euratom Research and Training Programme 2021–2025 under grant agreement No 101164616.

Conflicts of interest

The authors have nothing to disclose.

Data availability statement

Data associated with this article, except those that cannot be disclosed due to legal reason, are available in https://www.safeg.eu/documents.

Author contribution statement

Boris Kvizda: Writing of original draft, 1. Introduction, 4. Advanced materials and technologies, 6. Emergency Core Cooling System of ALLEGRO. Slavomír Bebjak: 9. Future research and development. Gusztáv Mayer: 3. The core safety and proliferation resistance. Petr Vácha: 2. ALLEGRO design, 5. Decay Heat Removal. Tomáš Melichar: 7. S-Allegro experiments. Congjin Ding: 8. Education and Training.

Glossary

AFA: Alumina-Forming Austenitic (AFA) stainless steels

CFD: Computational fluid dynamics

CSD: Control and Shutdown Device

DEC: Design Extension Conditions

DED: Directed Energy Deposition

ECCS: Emergency Core Cooling System

ESFAS: Engineered Safety Feature Actuation Systems

ESNII: European Sustainable Nuclear Industrial Initiative

ETDR: Experimental Technology Demonstration Reactor

GIF: Generation IV International Forum

LOCA: Loss of Coolant Accidents

MOX: Nuclear fuel consisting of uranium oxide and plutonium oxide

ODS: Oxide Dispersion-Strengthened material

SiC(f): Silicon Carbide (fiber)

SNETP: Sustainable Nuclear Energy Technology Platform

UOX: Nuclear fuel consisting of uranium oxide

UPuC: Nuclear fuel consisting of uranium carbide and plutonium carbide

References

- B. Hatala et al., Project SafeG: Safety of GFR through innovative materials, technologies and processes, in Proceedings of the 20th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-29), (virtual meeting) (2021) [Google Scholar]

- F. Bertrand et al., Safety approach for ETDR and elements regarding the safety options, GCFR-DEL-016 [Google Scholar]

- Ch. Poette et al., ETDR, The European Union's Experimental Gas-Cooled Fast Reactor Project, PHYSOR’08: International Conference on the Physics of Reactors ‘Nuclear Power: A Sustainable Resource’; Interlaken (Switzerland); 14–19 Sep 2008; ISBN 978-3-9521409-5-6 [Google Scholar]

- B. Kvizda et al., ALLEGRO Gas-cooled Fast Reactor (GFR) demonstrator thermal hydraulic benchmark, Nucl. Eng. Des. (2019), https://doi.org/10.1016/j.nucengdes.2019.02.006 [Google Scholar]

- G. Mayer et al., Selection of the enveloping transients of ALLEGRO reactor at the beginning of the SafeG project, in The 19th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-19), Log nr.: 35548, Brussels, Belgium, March 6–11 (2022) [Google Scholar]

- Z. Hózer et al., ALLEGRO fuel related acceptance criteria, MTA-EK, Budapest, 2016 [Google Scholar]

- P. Pónya et al., Core optimization of UO2 fuelled ALLEGRO reactor, Ann. Nucl. Energy 178, 109374 (2022), https://doi.org/10.1016/j.anucene.2022.109374 [CrossRef] [Google Scholar]

- P. Pónya et al., Evaluation of reflector design of ALLEGRO refractory core, Ann. Nucl. Energy 206, 110602 (2024), https://doi.org/10.1016/j.anucene.2024.110602 [CrossRef] [Google Scholar]

- N. Tauveron, I. Dor, F. Bentivoglio, Study of nitrogen injection to enhance forced convection for GFR demonstrator ALLEGRO, in Proceeding of ASME2010 Power Conference, (July 13–15) Chicago, Illinois USA pp. 823–834 (2010) https://doi.org/10.1115/POWER2010-27137 [Google Scholar]

- B. Kvizda, S. Bebjak, Optimization of the Emergency Coolant Injection System of ALLEGRO, in Proceedings of the 20 th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-20), August 20–25, 2023, Washington, D.C., Pages 3126–3139 https://doi.org/10.13182/NURETH20-41391 [Google Scholar]

- C. Ding, B. Kvizda et al., CFD simulation of injection point design for Emergency Core Cooling System of ALLEGRO, Ann. Nucl. Energy 213, 111084 (2025), https://doi.org/10.1016/j.anucene.2024.111084 [CrossRef] [Google Scholar]

- T. Melichar et al., in Experimental programme within the development of the ALLEGRO GFR demonstrator, Jaderna Energie (2020. Online); ISSN 2694-9024; Worldcat; 3 pp. 38–41, https://jadernaenergie.online/wp-content/uploads/2022/07/CVR_casopis_jaderna_energie_03_2022_web.pdf [Google Scholar]

- J.J. Jasinski, T. Stasiak et al., Microstructure and phase investigation of FeCrAl-Y2O3 ODS steels with different Ti and V contents, J. Nucl. Mater. 586, 154700 (2023), https://doi.org/10.1016/j.jnucmat.2023.154700 [CrossRef] [Google Scholar]

Cite this article as: Boris Kvizda, Slavomír Bebjak, Gusztáv Mayer, Petr Vácha, Tomáš Melichar, Congjin Ding. Advancing Gas-cooled Fast Reactor Technology: Outcomes of the Euratom SafeG Project on ALLEGRO Research and Development, EPJ Nuclear Sci. Technol. 11, 25 (2025). https://doi.org/10.1051/epjn/2025021.

All Tables

All Figures

|

Fig. 1. ALLEGRO 75 MW. |

| In the text | |

|

Fig. 2. ALLEGRO system arrangement. |

| In the text | |

|

Fig. 3. The optimized ALLEGRO MOX_v2 core. |

| In the text | |

|

Fig. 4. Macrograph of the SiC/SiCf samples. |

| In the text | |

|

Fig. 5. DHR heat exchanger produced by advanced manufacturing process – material IN617. |

| In the text | |

|

Fig. 6. SEM backscattered electron images of microstructure of selected FeCrAl-ODS bulk samples. |

| In the text | |

|

Fig. 7. Decay heat removal loop (left) and the principle of operation of the preconditioning device (right). |

| In the text | |

|

Fig. 8. Comparison of mass flow rate of primary coolant (left) and power dissipated by the DHR loop (right) between the legacy and the innovative passive DHR system. |

| In the text | |

|

Fig. 9. Maximum fuel cladding temperature. |

| In the text | |

|

Fig. 10. The mass flow rate in the hottest channel. |

| In the text | |

|

Fig. 11. Injection path lines for LOCA 100 mm at 28 s (RPV bottom point). |

| In the text | |

|

Fig. 12. Injection path lines for LOCA 100 mm at 10 s (RPV side point). |

| In the text | |

|

Fig. 13. S-Allegro Integral Test Facility. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.